化工学报 ›› 2020, Vol. 71 ›› Issue (2): 889-898.DOI: 10.11949/0438-1157.20190919

• 材料化学工程与纳米技术 • 上一篇

刘丽雪1,2( ),张少峰1(

),张少峰1( ),赵长伟2,宝乐尔呼2,俞灵2,王军2

),赵长伟2,宝乐尔呼2,俞灵2,王军2

收稿日期:2019-08-12

修回日期:2019-12-12

出版日期:2020-02-05

发布日期:2020-02-05

通讯作者:

张少峰

作者简介:刘丽雪(1992—),女,硕士研究生, 基金资助:

Lixue LIU1,2( ),Shaofeng ZHANG1(

),Shaofeng ZHANG1( ),Changwei ZHAO2,Erhu BAOLE2,Ling YU2,Jun WANG2

),Changwei ZHAO2,Erhu BAOLE2,Ling YU2,Jun WANG2

Received:2019-08-12

Revised:2019-12-12

Online:2020-02-05

Published:2020-02-05

Contact:

Shaofeng ZHANG

摘要:

采用β-环糊精(β-CD)作为水相单体,均苯三甲酰氯(TMC)为油相单体,通过界面聚合法制备高通量的β-CD/TMC复合纳滤膜,利用细孔模型和静电排斥-立体位阻模型探究染料分离机理。采用红外光谱仪、场发射电子显微镜、接触角测量仪及Zeta电位分析仪进行分析表征。结果表明,红外光谱中出现了酯基官能团的特征峰;Zeta电位分析表明所制备的复合纳滤膜表面荷负电;SEM图像结构和接触角数值表明β-CD浓度为4.0%时,膜表面出现大量褶皱,膜的亲水性更好,0.2 MPa压力下,纯水通量可达207.81 L·m -2·h -1,对染料刚果红(CR)、孟加拉玫瑰红(RB)、活性艳红X-3B、亚甲基蓝(MB)的截留率分别为100%、99.05%、97.65%、32.92%;6 h连续运行实验,通量呈现先下降后稳定的趋势,对染料活性艳红X-3B的截留率始终高于97%。

中图分类号:

刘丽雪, 张少峰, 赵长伟, 宝乐尔呼, 俞灵, 王军. β-环糊精为水相单体的复合纳滤膜制备及染料截留性能[J]. 化工学报, 2020, 71(2): 889-898.

Lixue LIU, Shaofeng ZHANG, Changwei ZHAO, Erhu BAOLE, Ling YU, Jun WANG. Preparation of composite nanofiltration membrane with β-cyclodextrin as aqueous monomer and dye rejection properties[J]. CIESC Journal, 2020, 71(2): 889-898.

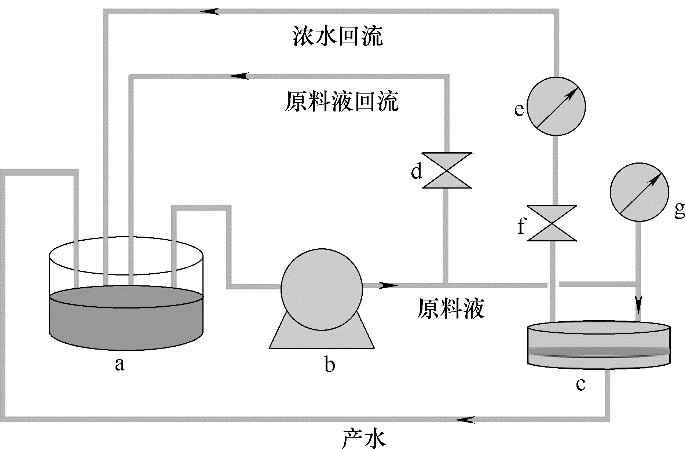

图2 平板膜性能测试装置

Fig.2 Schematic diagram of flat membrane experiment devicea—feed tank;b—feed pump;c—membrane module;d—flow valve;e—flowmeter;f—pressure valve;g—pressure gage

| 染料名称 | 摩尔质量/(g·mol -1) | Stokes半径/nm | 染料类型 | 价态 | 最大吸收波长/nm |

|---|---|---|---|---|---|

| Rose bengal(RB) | 1017 | 0.779 | 非离子型 | 0 | 548 |

| reactive red X-3B | 616 | 0.628 | 非离子型 | 0 | 537 |

| Congo red(CR) | 696 | 0.662 | 阴离子型 | -2 | 498 |

| methylene blue(MB) | 319 | 0.471 | 阳离子型 | +1 | 664 |

表1 不同类型染料数据

Table 1 Data of different dyes

| 染料名称 | 摩尔质量/(g·mol -1) | Stokes半径/nm | 染料类型 | 价态 | 最大吸收波长/nm |

|---|---|---|---|---|---|

| Rose bengal(RB) | 1017 | 0.779 | 非离子型 | 0 | 548 |

| reactive red X-3B | 616 | 0.628 | 非离子型 | 0 | 537 |

| Congo red(CR) | 696 | 0.662 | 阴离子型 | -2 | 498 |

| methylene blue(MB) | 319 | 0.471 | 阳离子型 | +1 | 664 |

| Membrane | TMC in organic phase/%(质量) | β-CD in aqueous phase/%(质量) | Zeta potential/mV |

|---|---|---|---|

| PES | 0 | 0 | -30.70 |

| β-CD1.0/TMC | 0.2 | 1.0 | -34.93 |

| β-CD1.8/TMC | 0.2 | 1.8 | -35.36 |

| β-CD3.0/TMC | 0.2 | 3.0 | -44.85 |

| β-CD4.0/TMC | 0.2 | 4.0 | -53.10 |

| β-CD5.0/TMC | 0.2 | 5.0 | -58.83 |

表2 PES与β-CD/TMC复合纳滤膜的Zeta电位

Table 2 Zeta potential of surface of PES and β-CD/TMC composite nanofiltration membrane

| Membrane | TMC in organic phase/%(质量) | β-CD in aqueous phase/%(质量) | Zeta potential/mV |

|---|---|---|---|

| PES | 0 | 0 | -30.70 |

| β-CD1.0/TMC | 0.2 | 1.0 | -34.93 |

| β-CD1.8/TMC | 0.2 | 1.8 | -35.36 |

| β-CD3.0/TMC | 0.2 | 3.0 | -44.85 |

| β-CD4.0/TMC | 0.2 | 4.0 | -53.10 |

| β-CD5.0/TMC | 0.2 | 5.0 | -58.83 |

| 水相 | 油相 | 制膜方法 | 通量/(L·m -2·h -1) | 截留率/% | 压力/MPa | 文献 |

|---|---|---|---|---|---|---|

| TEOA ① and β-CD | TMC | IP | 26 | Na 2SO 4 78 | 0.6 | [ |

| β-CD | TC ② | IP | 9.6 | MO ③ 91 | 0.1 | [ |

| β-CD | TMC | IP | 5.6 | MO 86 | 0.1 | [ |

β-CD | TMC | IP | 119.2 106.9 | CR 100 X-3B 97.6 | 0.2 | this work |

表3 β-CD为水相单体在本研究和文献中的比较

Table 3 Comparison of β-CD as aqueous monomer in this work and literatures

| 水相 | 油相 | 制膜方法 | 通量/(L·m -2·h -1) | 截留率/% | 压力/MPa | 文献 |

|---|---|---|---|---|---|---|

| TEOA ① and β-CD | TMC | IP | 26 | Na 2SO 4 78 | 0.6 | [ |

| β-CD | TC ② | IP | 9.6 | MO ③ 91 | 0.1 | [ |

| β-CD | TMC | IP | 5.6 | MO 86 | 0.1 | [ |

β-CD | TMC | IP | 119.2 106.9 | CR 100 X-3B 97.6 | 0.2 | this work |

| 1 | Ning X A, Lin M Q, Shen L Z, et al. Levels, composition profiles and risk assessment of polycyclic aromatic hydrocarbons (PAHs) in sludge from ten textile dyeing plants[J]. Environmental Research, 2014, 132: 112- 118. |

| 2 | Jhaveri J H, Murthy Z V P. A comprehensive review on anti-fouling nanocomposite membranes for pressure driven membrane separation processes[J]. Desalination, 2016, 379: 137- 154. |

| 3 | Park H B, Kamcev J, Robeson L M, et al. Maximizing the right stuff: the trade-off between membrane permeability and selectivity[J]. Science, 2017, 356( 6343): 1138- 1146. |

| 4 | 蔡卫滨, 夏阳, 王玉军, 等. 白炭黑填充PDMS/PVDF复合膜的纳滤分离性能及传质特性[J]. 化工学报, 2015, 66( 7): 2555- 2564. |

| Cai W B, Xia Y, Wang Y J, et al. Nanofiltration performance and mass transfer characteristics of PDMS/PVDF composite membranes filled with white carbon black[J]. CIESC Journal, 2015, 66( 7): 2555- 2564. | |

| 5 | Hilal N, Al-Zoubi H, Darwish N A, et al. A comprehensive review of nanofiltration membranes: treatment, pretreatment, modelling, and atomic force microscopy[J]. Desalination, 2004, 170( 3): 281- 308. |

| 6 | 唐元晖, 扈阳, 燕至琴, 等. 高浓度含盐草甘膦溶液的纳滤分离实验研究[J]. 化工学报, 2019, 70( 7): 2574- 2583. |

| Tang Y H, Hu Y, Yan Z Q, et al. Experimental study on nanofiltration separation of high concentrated saline glyphosate solution[J]. CIESC Journal, 2019, 70( 7): 2574- 2583. | |

| 7 | Babu J, Murthy Z V P. Treatment of textile dyes containing wastewaters with PES/PVA thin film composite nanofiltration membranes[J]. Separation and Purification Technology, 2017, ( 183): 66- 72. |

| 8 | Pan F S, Guo W X, Su Y L, et al. Direct growth of covalent organic framework nanofiltration membranes on modified porous substrates for dyes separation[J]. Separation and Purification Technology, 2019, ( 215): 582- 589. |

| 9 | 邱实, 吴礼光, 张林, 等. 纳滤分离机理[J]. 水处理技术, 2009, 35( 1): 20- 24. |

| Qiu S, Wu L G, Zhang L, et al. Seperation mechanisms of nanofiltration[J]. Technology of Water Treatment, 2009, 35( 1): 15- 19. | |

| 10 | 黄裕, 张晗, 董秉直, 等. 纳滤膜去除卡马西平的影响因素研究[J]. 环境科学, 2011, 32( 3): 705- 710. |

| Huang Y, Zhang H, Dong B Z, et al. Researches on factors affecting the removal of carbamazepine by nanofiltration membranes[J]. Environment Science, 2011, 32( 3): 705- 710. | |

| 11 | Wang X L, Tsuru T, Nakao S I, et al. The electrostatic and steric-hindrance model for the transport of charged solutes through nanofiltration membranes[J]. Journal of Membrane Science, 1997, 135( 1): 19- 32. |

| 12 | Attarde D, Jain M, Gupta S K. Modeling of a forward osmosis and a pressure-retarded osmosis spiral wound module using the Spiegler-Kedem model and experimental validation[J]. Separation and Purification Technology, 2016, 164: 182- 197. |

| 13 | 张菁, 张庆印, 王泽瑞. 纳滤膜的制备技术[J]. 现代化工, 2018, 38( 4): 27- 31+33. |

| Zhang J, Zhang Q Y, Wang Z R. Preparation technology of nanofiltration membrane[J]. Modern Chemical Industry, 2018, 38( 4): 27- 31+33. | |

| 14 | 时雅滨, 张学彬, 田明, 等. 纳滤膜的制备及其应用现状[J]. 化工时刊, 2018, 32( 10): 39- 42. |

| Shi Y B, Zhang X B, Tian M, et al. Study on the preparation and application of nanofiltration membrane[J]. Chemical Industry Times, 2018, 32( 10): 39- 42. | |

| 15 | Freitas T V, Sousa E A, Fuzari Jr G C, et al. Different morphologies of polyaniline nanostructures synthesized by interfacial polymerization[J]. Materials Letters, 2018, 224: 42- 45. |

| 16 | Hu R R, Zhang R J, He Y J, et al. Graphene oxide-in-polymer nanofiltration membranes with enhanced permeability by interfacial polymerization[J]. Journal of Membrane Science, 2018, 564: 813- 819. |

| 17 | Shen L, Hung W S, Zuo J, et al. High-performance thin-film composite polyamide membranes developed with green ultrasound-assisted interfacial polymerization[J]. Journal of Membrane Science, 2019, 570/ 571: 112- 119. |

| 18 | 张润楠, 李亚飞, 苏延磊, 等. 氨基化氧化石墨烯界面聚合制备超薄复合纳滤膜[J]. 化工学报, 2018, 69( 1): 435- 445. |

| Zhang R N, Li Y F, Su Y L, et al. Preparation of thin-film composite nanofiltration membranes with amino-functionalized graphene oxide by interfacial polymerization[J]. CIESC Journal, 2018, 69( 1): 435- 445. | |

| 19 | Misdan N, Lau W J, Ismail A F, et al. Study on the thin film composite poly (piperazine-amide) nanofiltration membrane: impacts of physicochemical properties of substrate on interfacial polymerization formation[J]. Desalination, 2014, 344: 198- 205. |

| 20 | 高爱环, 刘金盾, 张浩勤, 等. 聚哌嗪酰胺复合纳滤膜制备及其性能表征[J]. 高校化学工程学报, 2004, 18( 1): 28- 32. |

| Gao A H, Liu J D, Zhang H Q, et al. Preparation and characterization of poly-piperazinamide composite nanofiltration membrane[J]. Journal of Chemical Engineering of Chinese Universities, 2004, 18( 1): 28- 32. | |

| 21 | 李洪懿, 翟丁, 周勇, 等. 纳米聚苯胺改性聚哌嗪酰胺纳滤膜的制备[J]. 化工学报, 2015, 66( 1): 142- 148. |

| Li H Y, Zhai D, Zhou Y, et al. Polyamide composite NF membrane modified with polyaniline nanoparticles[J]. CIESC Journal, 2015, 66( 1): 142- 148. | |

| 22 | 俞昌朝, 储月霞, 沈江南, 等. 纳米碳管改性聚哌嗪酰胺复合纳滤膜的制备[J]. 高校化学工程学报, 2014, ( 1): 84- 91. |

| Yu C C, Chu Y X, Shen J N, et al. Preparation of polypiperazine amide composite nanofiltration membrane modified by carbon nanotubes[J]. Journal of Chemical Engineering of Chinese Universities, 2014, ( 1): 84- 91. | |

| 23 | Tsuru T, Sasaki S, Kamada T, et al. Multilayered polyamide membranes by spray-assisted 2-step interfacial polymerization for increased performance of trimesoyl chloride (TMC)/ m-phenylenediamine (MPD)-derived polyamide membranes [J]. Journal of Membrane Science, 2013, 446: 504- 512. |

| 24 | Yao Z, Guo H, Yang Z, et al. Reactable substrate participating interfacial polymerization for thin film composite membranes with enhanced salt rejection performance[J]. Desalination, 2018, 436: 1- 7. |

| 25 | 汤蓓蓓, 徐铜文, 武培怡. 界面聚合法制备复合膜[J]. 化学进展, 2007, ( 9): 202- 209. |

| Tang B B, Xu T W, Wu P Y. Preparation of thin film composite membrane by interfacial polymerization method[J]. Progress in Chemistry, 2007, ( 9): 202- 209. | |

| 26 | 王进, 赵长伟, 吴珍, 等. 氧化石墨烯/聚哌嗪酰胺复合纳滤膜在染料脱除中的应用研究[J]. 膜科学与技术, 2016, 36( 6): 86- 94. |

| Wang J, Zhao C W, Wu Z, et al. Applied research of graphene oxide polypiperazine-amide composite nanofiltration membrane in removal of dye wastewater[J]. Membrane Science and Technology, 2016, 36( 6): 86- 94. | |

| 27 | 许中煌, 雷萍萍, 洪昱斌, 等. 氧化石墨烯/碱式硫酸铝掺杂聚醚砜/聚酰胺复合纳滤膜的制备及其性能[J]. 化工学报, 2018, 69( 9): 4066- 4074. |

| Xu Z H, Lei P P, Hong Y B, et al. Preparation and performance of graphene oxide/basic aluminum sulfate doped polyethersulfone/polyamide composite nanofiltration membrane[J]. CIESC Journal, 2018, 69( 9): 4066- 4074. | |

| 28 | Chua M L, Xiao Y C, Chung T S. Modifying the molecular structure and gas separation performance of thermally labile polyimide-based membranes for enhanced natural gas purification[J]. Chemical Engineering Science, 2013, 104: 1056- 1064. |

| 29 | Askari M, Yang T, Chung T S. Natural gas purification and olefin/paraffin separation using cross-linkable dual-layer hollow fiber membranes comprising β-cyclodextrin[J]. Journal of Membrane Science, 2012, 423/ 424: 392- 403. |

| 30 | Kusumocahyo S P, Sumaru K, Kanamori T, et al. Synthesis and characterization of an ultrathin polyion complex membrane containing β-cyclodextrin for separation of organic isomers[J]. Journal of Membrane Science, 2004, 230( 1/2): 171- 174. |

| 31 | Wang Y, Chung T S, Wang H, et al. Butanol isomer separation using polyamide-imide/CD mixed matrix membranes via pervaporation [J]. Chemical Engineering Science, 2009, 64( 24): 5198- 5209. |

| 32 | Morin-Crini N, WintertonP, Fourmentin S, et al. Water-insoluble β-cyclodextrin–epichlorohydrin polymers for removal of pollutants from aqueous solutions by sorption processes using batch studies: a review of inclusion mechanisms[J]. Progress in Polymer Science, 2018, 78: 1- 23 |

| 33 | Wang Y, Chung T S, Wang H. Polyamide–imide membranes with surface immobilized cyclodextrin for butanol isomer separation via pervaporation [J]. AIChE Journal, 2011, 57( 6): 1470- 1484. |

| 34 | Alsbaiee A, Smith B J, Xiao L, et al. Rapid removal of organic micropollutants from water by a porous β-cyclodextrin polymer[J]. Nature, 2015, 529: 190. |

| 35 | Adams F V, Nxumalo E N, Krause R W M, et al. Preparation and characterization of polysulfone/β-cyclodextrin polyurethane composite nanofiltration membranes[J]. Journal of Membrane Science, 2012, 405/ 406: 291- 299. |

| 36 | Villalobos L F, Huang T F, Peinemann K V. Cyclodextrin films with fast solvent transport and shape-selective permeability[J]. Advanced Materials, 2017, 29( 26): 1606641. |

| 37 | Yu Z Y, Pan Y, He Y, et al. Preparation of a novel anti-fouling β-cyclodextrin-PVDF membrane[J]. RSC Advances, 2015, 5( 63): 51364- 51370. |

| 38 | Deng J, Liu X, Zhang S, et al. Versatile and rapid post functionalization from cyclodextrin modified host polymeric membrane substrate[J]. Langmuir, 2015, 31( 35): 9665- 9674. |

| 39 | Wu H Q, Tang B B, Wu P Y. Preparation and characterization of anti-fouling β-cyclodextrin/polyester thin film nanofiltration composite membrane[J]. Journal of Membrane Science, 2013, 428: 301- 308. |

| 40 | Liu J, Hua D, Zhang Y, et al. Precise molecular sieving architectures with Janus pathways for both polar and nonpolar molecules[J]. Advanced Materials, 2018, 30( 11): 1705933. |

| 41 | Tang Y J, Shen B J, Huang B Q, et al. High permselectivity thin-film composite nanofiltration membranes with 3D microstructure fabricated by incorporation of beta cyclodextrin[J]. Separation and Purification Technology, 2019, 227: 115718. |

| 42 | 张显球, 张林生, 吕锡武, 等. 纳滤分离中性溶质的截留分子量参数细孔模型[J]. 化工学报, 2007, 58( 8): 2033- 2037. |

| Zhang X Q, Zhang L S, Lyu X W, et al. Steric-hindrance pore model for separation of uncharged solutes by nanofiltration with molecular weight cut-off as parameters[J]. Journal of Chemical Industry and Engineering(China), 2007, 58( 8): 2033- 2037. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [5] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [6] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [9] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [10] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [11] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [12] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [13] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [14] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [15] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号