化工学报 ›› 2020, Vol. 71 ›› Issue (7): 2956-2972.DOI: 10.11949/0438-1157.20200051

收稿日期:2020-01-14

修回日期:2020-02-27

出版日期:2020-07-05

发布日期:2020-07-05

通讯作者:

饶中浩

作者简介:刘昌会(1987—),男,博士,讲师,基金资助:

Changhui LIU1,2( ),Wenbo HUANG3,Yanlong GU4,Zhonghao RAO1,2(

),Wenbo HUANG3,Yanlong GU4,Zhonghao RAO1,2( )

)

Received:2020-01-14

Revised:2020-02-27

Online:2020-07-05

Published:2020-07-05

Contact:

Zhonghao RAO

摘要:

聚苯乙烯是塑料材料家族中的重要组成部分,它具有质轻、隔热、防水、廉价等一系列优点。由于它的化学稳定性优异,自然界很难将其直接降解,通常采用填埋或焚烧进行处理,不仅对环境造成了严重的污染,同时也是资源的严重浪费。近年来,由于化学及材料科学快速发展,针对废弃聚苯乙烯回收及高值化研究已经得到广泛关注。本文从环境和能源角度详细综述了近年来废弃聚苯乙烯高值化应用的研究进展,从废弃聚苯乙烯的高值化方式和产物出发分为以下三个主要部分:通过物理或化学手段将废弃聚苯乙烯塑料转化为高分子功能材料;作为模板剂或碳源制备多孔碳材料;将废弃聚苯乙烯塑料裂解为小分子有机物。

中图分类号:

刘昌会,黄文博,顾彦龙,饶中浩. 废弃聚苯乙烯塑料在环境与能源中的高值化应用进展[J]. 化工学报, 2020, 71(7): 2956-2972.

Changhui LIU,Wenbo HUANG,Yanlong GU,Zhonghao RAO. Recent advances in high value added reuse of waste polystyrene in environment and energy[J]. CIESC Journal, 2020, 71(7): 2956-2972.

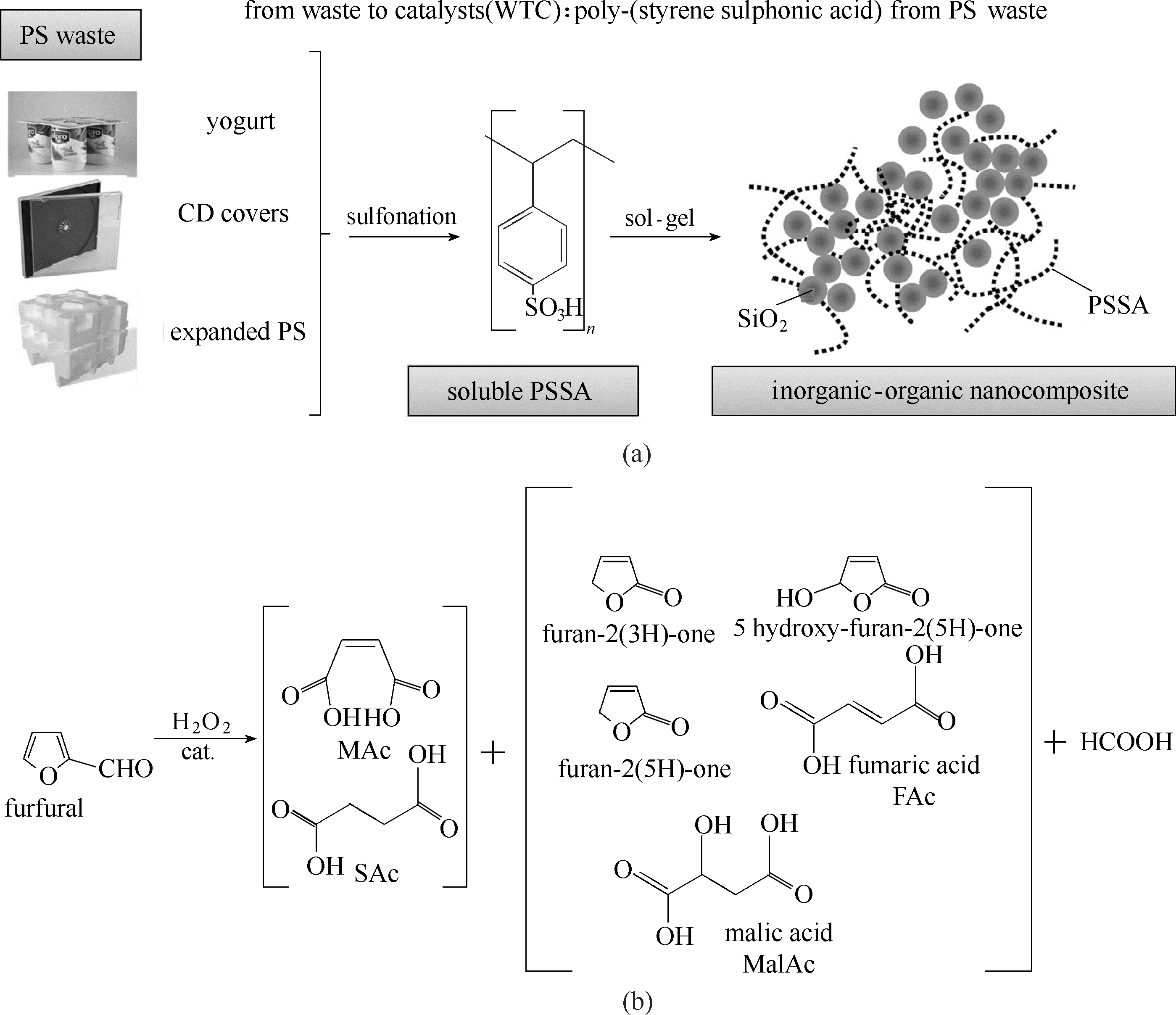

图1 废弃聚苯乙烯转化为非均相酸催化剂用于生物质降解[36]

Fig.1 An acid catalyst from polystyrene waste for reactions of interest in biomass valorization[36](a) schematic illustration of preparation process; (b) utilized into biomass valorization

图2 废弃聚苯乙烯用于超交联多孔材料的制备及其对于二氧化碳的吸附研究[44]

Fig.2 Transform waste expanded polystyrene foam into hyper-crosslinked polymers for carbon dioxide capture and separation[44]

图3 废弃聚苯乙烯用于超交联多孔材料的制备及其对于刚果红的吸附研究[46]

Fig.3 Conversion of post-consumer waste polystyrene into a high value adsorbent and its sorptive properties for congo red removal[46](a) synthetic pathway; (b) N2 adsorption and the corresponding Horvath-Kawazoe pore size distributions

图4 废弃聚苯乙烯在热能存储方面的应用[57]

Fig.4 Use of waste polystyrene in thermal energy storage[57](a) chemical conversion involved in the preparation of waste polystyrene based thermal energy storage materials; (b) schematic illustration for preparation process; (c) scanning electron microscope (SEM) of the obtained material; (d) differential scanning calorimetry (DSC) curve of phase change materials composite

图5 废弃聚苯乙烯用于多孔碳基空心球的制备及其对于甲基蓝的吸附研究[63]

Fig.5 Hollow spherical sludge chars (HSCs) prepared from sewage sludge and polystyrene foam wastes[63](a) schematic illustration of the preparation process; (b) digital images of samples with different shell thickness; (c) adsorption kinetics of methylene blue onto HSCs under the different conditions; (d) reuse performance of HSCs

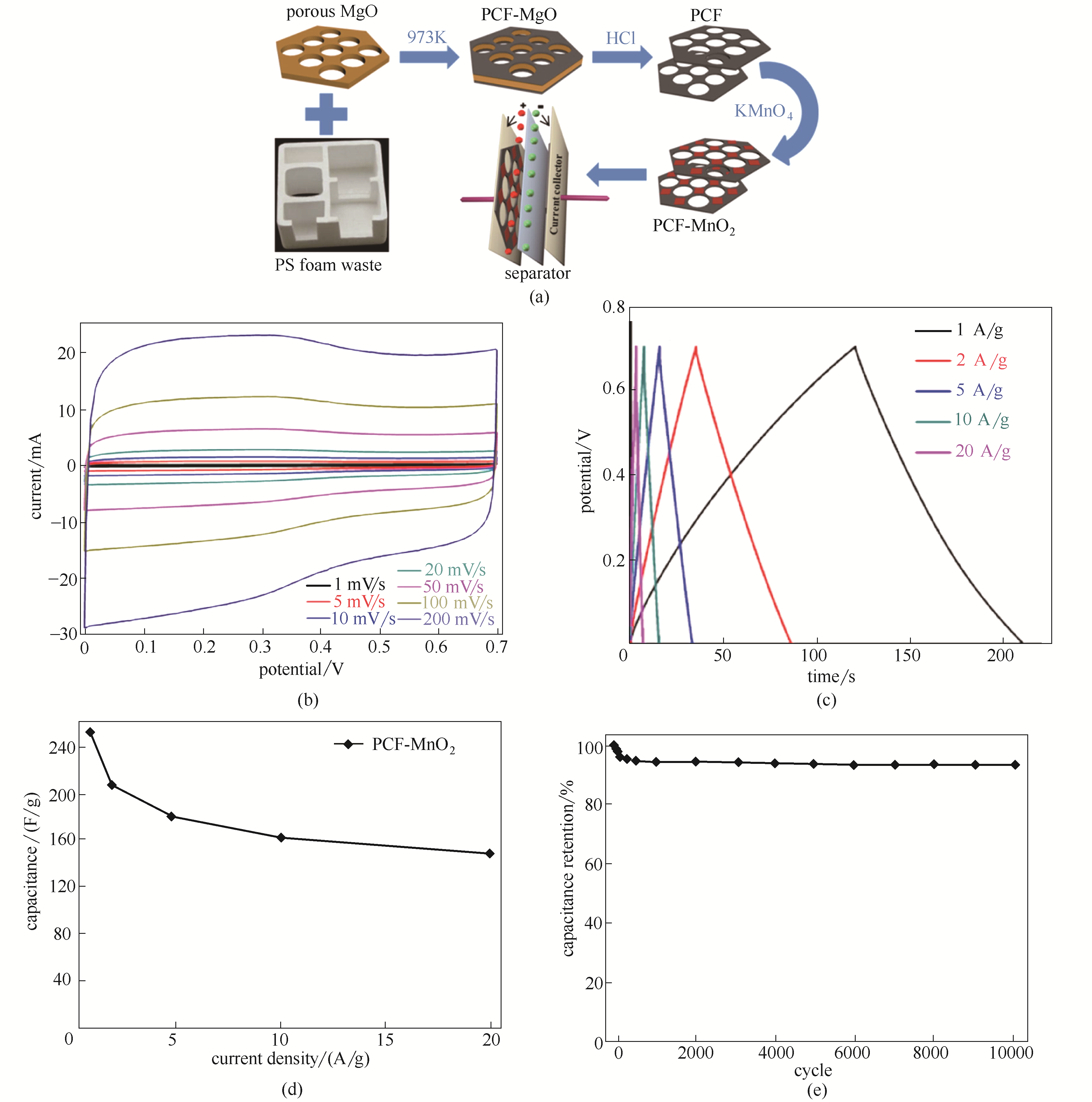

图6 以废弃聚苯乙烯为原料制备多孔碳薄片及其在超级电容器方面的应用[65]

Fig.6 From polystyrene waste to porous carbon flake and potential application in supercapacitors[65](a) schematic illustration for preparation process; (b) cyclic voltammetry (CV) and (c) galvanostatic charge/discharge (GCD) curves of PCF-MnO2; (d) specific capacities of PCF-MnO2 at different current densities; (e) cycling stability of PCF-MnO2 at 10 A/g

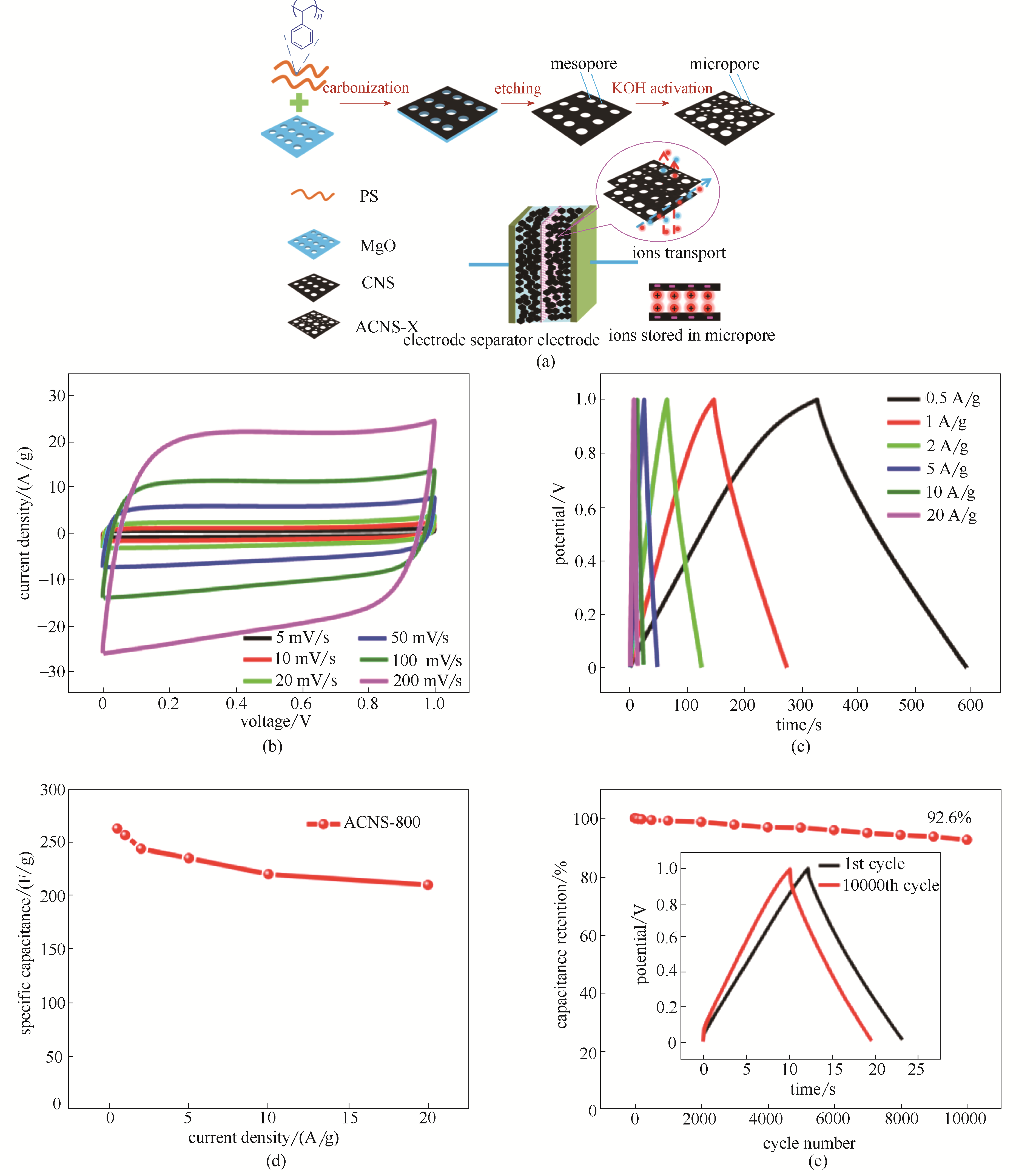

图7 以废弃聚苯乙烯为原料制备层级多孔碳材料及其在超级电容器方面的应用[66]

Fig.7 Recycling of waste polystyrene into hierarchical porous carbon nanosheets and potential application in supercapacitors[66](a) schematic illustration for preparation process; (b) CV curves of ACNS-800 tested at 5—200 mV/s; (c) GCD curves of ACNS-800 tested at 0.5-20 A/g; (d) charge-discharge rate performance of ACNS-800; (e) cycling performance at 10 A/g (inset: comparison of the first and the last charging-discharging cycle in cyclic stability test)

图8 以废弃聚苯乙烯为原料经超交联法制备多孔碳材料及其在超级电容器方面的应用[67]

Fig.8 Porous carbon derived from waste polystyrene by hypercrosslinking and application in supercapacitor[67](a) schematic illustration for preparation process; (b) CV curves of porous carbon at 5—100 mV/s; (c) GCD curves of porous carbon at 1—20 A/g; (d) the specific capacitance of porous carbon electrode with different current density and comparison with other carbon materials; (e) Nyquist plot of porous carbon

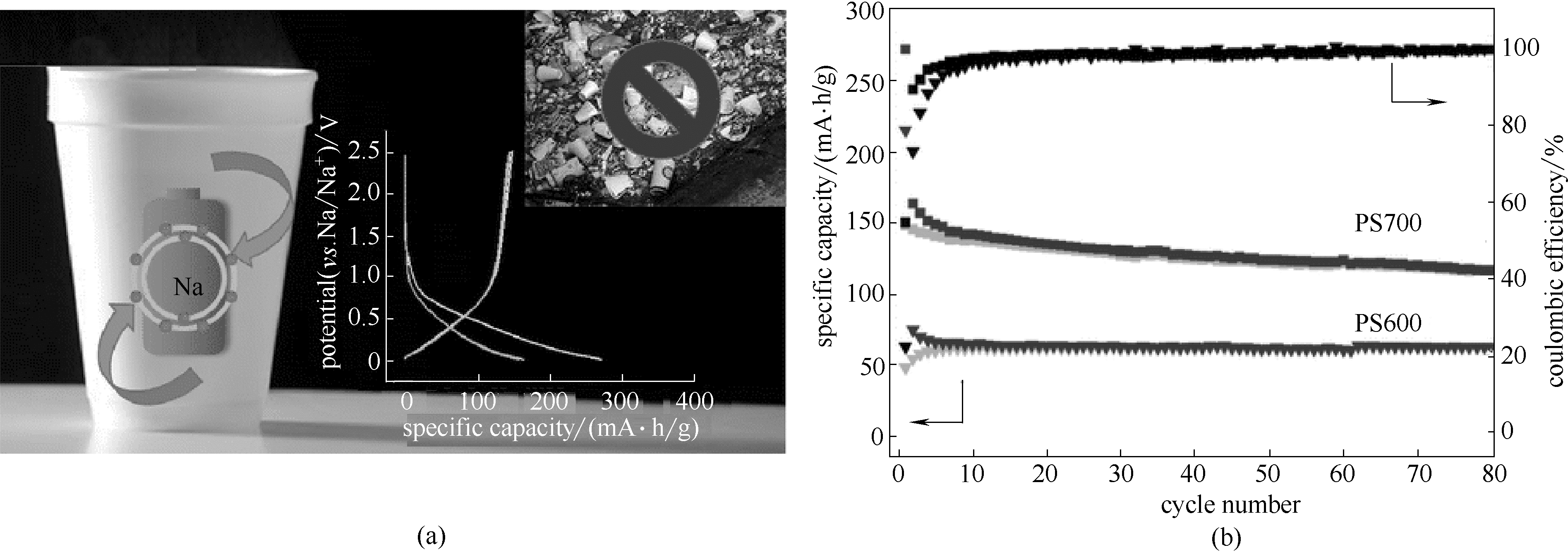

图9 废弃聚苯乙烯塑料杯在钠离子电池负极方面的应用[68]

Fig.9 Transforming waste polystyrene cups into negative electrode materials for sodium ion batteries[68](a) schematic illustration for preparation process; (b) electro-chemical performance of the obtained materials

图10 将废弃聚苯乙烯转化为多孔碳材料及其在二氧化碳和氢气存储方面的应用[75]

Fig.10 Conversion of mixed plastics into porous carbon nanosheets with high performances in uptake of carbon dioxide and storage of hydrogen[75](a) schematic illustration for preparation process; (b) carbon dioxide and (c) hydrogen adsorption isotherms

图11 以废弃聚苯乙烯为原料经空气化冷凝法制备工业小分子化合物和纳米材料[85]

Fig.11 Vacuum-gasification-condensation of waste toner to produce industrial chemicals and nanomaterials[85](a) schematic illustration for preparation process; (b) pyrolysis route of polystyrene and polyacrylate

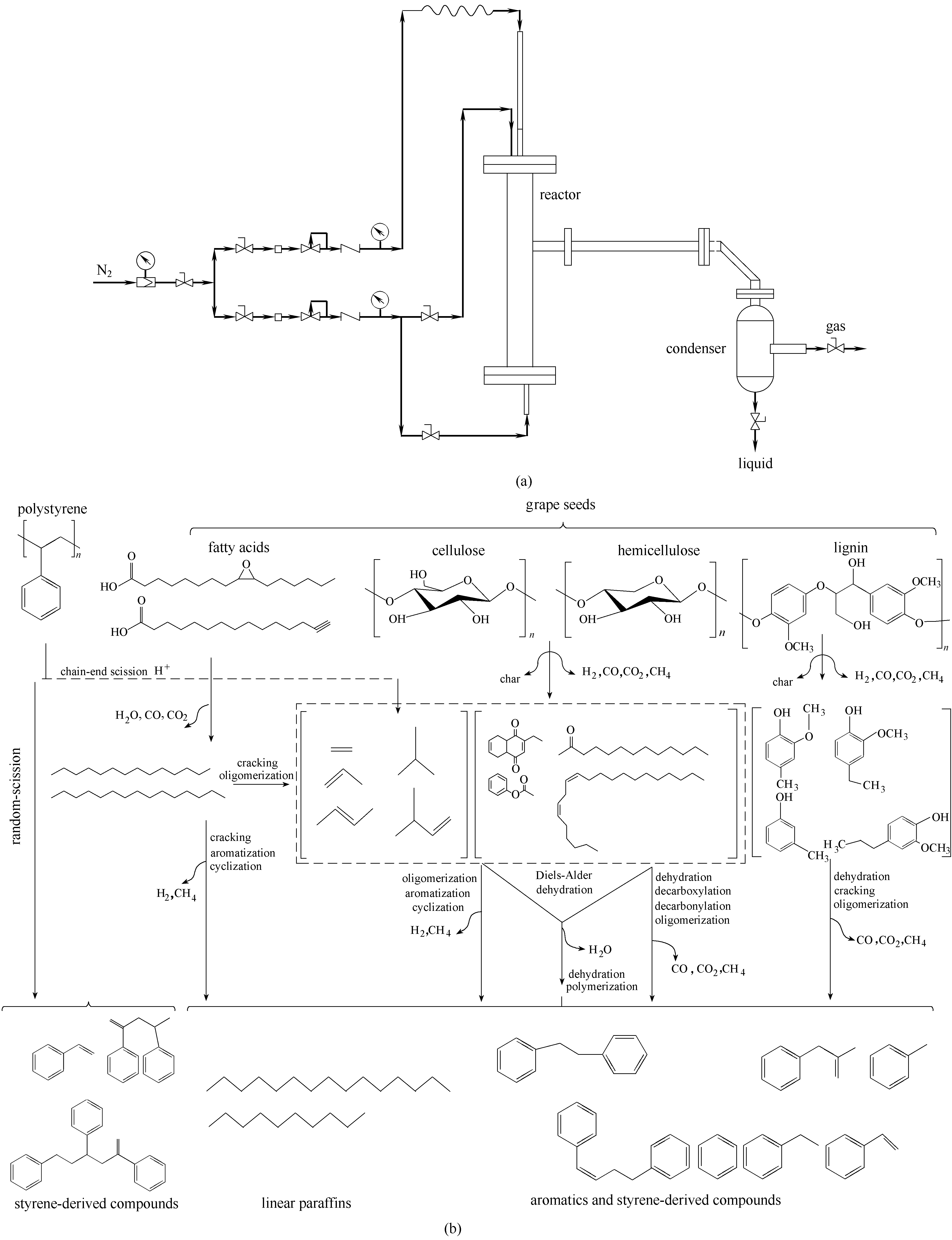

图12 葡萄籽和聚苯乙烯共热解制备生物燃料[86]

Fig.12 Drop-in biofuels from co-pyrolysis of grape seeds and polystyrene[86](a) fixed-bed reactor scheme used for determining co-pyrolysis performance; (b) simplified reaction mechanism proposed for the co-pyrolysis of grape seeds and polystyrene

| 1 | Wang X D, Chen B, Wang H F, et al. Adhesion between submicrometer polystyrene spheres[J]. Powder Technology, 2011, 214(3): 447-450. |

| 2 | Sommer A P, Lotan N. Controls needed to reduce problem of plastic contamination[J]. Nature, 2010, 465(7296): 289-289. |

| 3 | Martinho G, Pires A, Saraiva L, et al. Composition of plastics from waste electrical and electronic equipment (WEEE) by direct sampling[J]. Waste Management, 2012, 32(6): 1213-1217. |

| 4 | Mangalara S C H, Varughese S. Green recycling approach to obtain nano- and microparticles from expanded polystyrene waste[J]. ACS Sustainable Chemistry & Engineering, 2016, 4(11): 6095-6100. |

| 5 | Sekhar V C, Nampoothiri K M, Mohan A J, et al. Microbial degradation of high impact polystyrene (HIPS), an e-plastic with decabromodiphenyl oxide and antimony trioxide[J]. Journal of Hazardous Materials, 2016, 318: 347-354. |

| 6 | Kubowicz S, Booth A M. Biodegradability of plastics: challenges and misconceptions[J]. Environmental Science & Technology, 2017, 51(21): 12058-12060. |

| 7 | Mattsson K, Ekvall M T, Hansson L A, et al. Altered behavior, physiology, and metabolism in fish exposed to polystyrene nanoparticles[J]. Environmental Science & Technology, 2015, 49(1): 553-561. |

| 8 | Hong S M, Hwang S S, Jeon B H, et al. Polypropylene/polyamide-6 blends based on commingled plastic wastes[J]. Journal of Materials Science, 2005, 40(14): 3857-3859. |

| 9 | Guo X, Wang J. The chemical behaviors of microplastics in marine environment: a review[J]. Marine Pollution Bulletin, 2019, 142: 1-14. |

| 10 | 李沛生. 废弃的一次性聚苯乙烯发泡餐盒回收处理工艺与技术[J]. 中国包装工业, 2010, (9): 20-23. |

| Li P S. Recycle process and technology of waste polystyrene foam based disposable food package[J]. China Packaging Industry, 2010, (9): 20-23. | |

| 11 | 刘西振, 张晓雅, 朱康, 等. 基于废弃聚苯乙烯泡沫的无溶剂快固化涂料[J]. 化工科技, 2019, 27(1): 40-43. |

| Liu X Z, Zhang X Y, Zhu K, et al. Solvent-free fast curing coating based on waste polystyrene foam[J]. Science and Technology in Chemical Industry, 2019, 27(1): 40-43. | |

| 12 | Raberg U, Hafren J. Biodegradation and appearance of plastic treated solid wood[J]. International Biodeterioration & Biodegradation, 2008, 62(2): 210-213. |

| 13 | Aguado R, Olazar M, Gaisan B, et al. Kinetics of polystyrene pyrolysis in a conical spouted bed reactor[J]. Chemical Engineering Journal, 2003, 92(1/2/3): 91-99. |

| 14 | Yang S, Bai S, Duan W, et al. Production of value-added composites from aluminum-plastic package waste via solid-state shear milling process[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(3): 4282-4293. |

| 15 | Gil-Jasso N D, Segura-González M A, Soriano-Giles G, et al. Dissolution and recovery of waste expanded polystyrene using alternative essential oils[J]. Fuel, 2019, 239: 611-616. |

| 16 | Maharana T, Negi Y S, Mohanty B. Review article: recycling of polystyrene[J]. Polymer-Plastics Technology and Engineering, 2007, 46(7): 729-736. |

| 17 | Shao Y, Jiang H, Li S, et al. Preparation of microencapsulated phase change materials based on expanded polystyrene foam wastes[J]. Micro & Nano Letters, 2018, 13(7): 998-1000. |

| 18 | Chanhoun M, Padonou S, Adjovi E C, et al. Study of the implementation of waste wood, plastics and polystyrenes for various applications in the building industry[J]. Construction and Building Materials, 2018, 167: 936-941. |

| 19 | Asaad J N, Tawfik S Y. Polymeric composites based on polystyrene and cement dust wastes[J]. Materials & Design, 2011, 32(10): 5113-5119. |

| 20 | Kuzhiyil N, Kong S C. Energy recovery from waste plastics by using blends of biodiesel and polystyrene in diesel engines[J]. Energy & Fuels, 2009, 23(5/6): 3246-3253. |

| 21 | Sharuddin S D A, Abnisa F, Daud W M A W, et al. Energy recovery from pyrolysis of plastic waste: study on non-recycled plastics (NRP) data as the real measure of plastic waste[J]. Energy Conversion and Management, 2017, 148: 925-934. |

| 22 | Rajaeifar M A, Abdi R, Tabatabaei M. Expanded polystyrene waste application for improving biodiesel environmental performance parameters from life cycle assessment point of view[J]. Renewable & Sustainable Energy Reviews, 2017, 74: 278-298. |

| 23 | Mohammadi P, Tabatabaei M, Nikbakht A M, et al. Simultaneous energy recovery from waste polymers in biodiesel and improving fuel properties[J]. Waste and Biomass Valorization, 2013, 4(1): 105-116. |

| 24 | 徐静颖, 卓建坤, 姚强. 燃煤有机污染物生成排放特性与采样方法研究进展[J]. 化工学报, 2019, 70(8): 2823-2834. |

| Xu J Y, Zhuo J K, Yao Q. Research progress on formation, emission characteristics and sampling methods of organic compounds from coal combustion[J]. CIESC Journal, 2019, 70(8): 2823-2834. | |

| 25 | 刘芳, 樊丰涛, 吕玉翠, 等. 石墨烯/TiO2复合材料光催化降解有机污染物的研究进展[J]. 化工学报, 2016, 67(5): 1635-1643. |

| Liu F, Fan F T, Lyu Y C, et al. Research progress on photocatalytic degradation of organic pollutants by graphene/TiO2 composite materials[J]. CIESC Journal, 2016, 67(5): 1635-1643. | |

| 26 | Zhang Z, Wang X, Long J, et al. H2O2 promoting effect on photocatalytic degradation of organic pollutants in an aqueous solution without an external H2 supply[J]. Applied Catalysis A-General, 2010, 380(1/2): 178-184. |

| 27 | Yang Q, Ma Y, Chen F, et al. Recent advances in photo-activated sulfate radical-advanced oxidation process (SR-AOP) for refractory organic pollutants removal in water[J]. Chemical Engineering Journal, 2019, 378: 122149. |

| 28 | Saka E T, Caglar Y. New Co(Ⅱ) and Cu(Ⅱ) phthalocyanine catalysts reinforced by long alkyl chains for the degradation of organic pollutants[J]. Catalysis Letters, 2017, 147(6): 1471-1477. |

| 29 | Chaukura N, Moyo W, Mamba B B, et al. Abatement of humic acid from aqueous solution using a carbonaceous conjugated microporous polymer derived from waste polystyrene[J]. Environmental Science and Pollution Research, 2018, 25(4): 3291-3300. |

| 30 | İ Altın, Sökmen M. Preparation of TiO2-polystyrene photocatalyst from waste material and its usability for removal of various pollutants[J]. Applied Catalysis B: Environmental, 2014, 144: 694-701. |

| 31 | de Assis G C, Skovroinski E, Leite V D, et al. Conversion of “waste plastic” into photocatalytic nanofoams for environmental remediation[J]. ACS Applied Materials Interfaces, 2018, 10(9): 8077-8085. |

| 32 | Song B, Tang Q, Wu W, et al. A novel in-situ synthesis and enhanced photocatalytic performance of Ag/AgBr/Ag2O/sulfonated polystyrene sphere heterostructure photocatalyst[J]. Materials Letters, 2017, 208: 92-94. |

| 33 | Li H M, Zhang Q G, Guo N N, et al. Ultrafine polystyrene nanofibers and its application in nanofibrous membranes[J]. Chemical Engineering Journal, 2015, 264: 329-335. |

| 34 | Meireles C D, Rodrigues G, de Assuncao R M N, et al. Production and characterization of membranes of recycled waste materials: cellulose acetate, obtained from sugarcane bagasse with polystyrene from plastics cups[J]. Polymer Engineering and Science, 2008, 48(8): 1443-1448. |

| 35 | Zhuang G L, Tseng H H, Wey M Y. Feasibility of using waste polystyrene as a membrane material for gas separation[J]. Chemical Engineering Research and Design, 2016, 111: 204-217. |

| 36 | Alonso-Fagúndez N, Laserna V, Alba-Rubio A C, et al. Poly-(styrene sulphonic acid): an acid catalyst from polystyrene waste for reactions of interest in biomass valorization[J]. Catalysis Today, 2014, 234: 285-294. |

| 37 | Huang J, Yin X Y, Yang J Y, et al. Solid protonic acids and luminescent carbon dots derived from waste expanded polystyrene[J]. Materials Letters, 2014, 117: 112-115. |

| 38 | Tan L, Tan B. Hypercrosslinked porous polymer materials: design, synthesis, and applications[J]. Chemical Society Reviews, 2017, 46(11): 3322-3356. |

| 39 | Tsyurupa M P, Davankov V A. Porous structure of hypercrosslinked polystyrene: state-of-the-art mini-review[J]. Reactive and Functional Polymers, 2006, 66(7): 768-779. |

| 40 | Yang Y, Tan B, Wood C D. Solution-processable hypercrosslinked polymers by low cost strategies: a promising platform for gas storage and separation[J]. Journal of Materials Chemistry A, 2016, 4(39): 15072-15080. |

| 41 | Jia Z, Wang K, Tan B, et al. Ruthenium complexes immobilized on functionalized knitted hypercrosslinked polymers as efficient and recyclable catalysts for organic transformations[J]. Advanced Synthesis & Catalysis, 2017, 359(1): 78-88. |

| 42 | Jia Z, Wang K, Li T, et al. Functionalized hypercrosslinked polymers with knitted N-heterocyclic carbene-copper complexes as efficient and recyclable catalysts for organic transformations[J]. Catalysis Science & Technology, 2016, 6(12): 4345-4355. |

| 43 | Li B, Guan Z, Wang W, et al. Highly dispersed Pd catalyst locked in knitting aryl network polymers for Suzuki-Miyaura coupling reactions of aryl chlorides in aqueous media[J]. Advanced Materials, 2012, 24(25): 3390-3395. |

| 44 | Fu Z, Jia J, Li J, et al. Transforming waste expanded polystyrene foam into hyper-crosslinked polymers for carbon dioxide capture and separation[J]. Chemical Engineering Journal, 2017, 323: 557-564. |

| 45 | Jia J, Fu Z, Wang L, et al. Conversion of waste polystyrene foam into sulfonated hyper-crosslinked polymeric adsorbents for cadmium removal in a fixed-bed column[J]. Chemical Engineering Research and Design, 2019, 142: 346-354. |

| 46 | Chaukura N, Mamba B B, Mishra S B. Conversion of post consumer waste polystyrene into a high value adsorbent and its sorptive properties for Congo Red removal from aqueous solution[J]. Journal of Environment Management, 2017, 193: 280-289. |

| 47 | Siyal A N, Memon S Q, Parveen S, et al. Chemical recycling of expanded polystyrene waste: synthesis of novel functional polystyrene-hydrazone surface for phenol removal[J]. Journal of Chemistry, 2013, 2013: 1-8. |

| 48 | Sułkowski W W, Nowak K, Sułkowska A, et al. Chemical recycling of polystyrene. Sulfonation with different sulfonation agents[J]. Molecular Crystals and Liquid Crystals, 2010, 523(1): 218/[790]-227/[799]. |

| 49 | Landim A S, Rodrigues Filho G, de Assunção R M N. Use of polystyrene sulfonate produced from waste plastic cups as an auxiliary agent of coagulation, flocculation and flotation for water and wastewater treatment in Municipal Department of Water and Wastewater in Uberlândia-MG, Brazil[J]. Polymer Bulletin, 2006, 58(2): 457-463. |

| 50 | Sułkowski W W, Wolińska A, Szołtysik B, et al. Preparation and properties of flocculants derived from polystyrene waste[J]. Polymer Degradation and Stability, 2005, 90(2): 272-280. |

| 51 | Chaukura N, Mukonza S S, Nkambule T I, et al. Photodegradation of humic acid in aqueous solution using a TiO2-carbonaceous hyper-cross-linked polystyrene polymer nanocomposite[J]. International Journal of Environmental Science and Technology, 2018, 16(3): 1603-1612. |

| 52 | Liu C, Rao Z, Zhao J, et al. Review on nanoencapsulated phase change materials: preparation, characterization and heat transfer enhancement[J]. Nano Energy, 2015, 13: 814-826. |

| 53 | Liu C, Rao Z. Challenges in various thermal energy storage technologies[J]. Science Bulletin, 2017, 62(4): 231-233. |

| 54 | Liu C, Song Y, Xu Z, et al. Highly efficient thermal energy storage enabled by a hierarchical structured hypercrosslinked polymer/expanded graphite composite[J]. International Journal of Heat and Mass Transfer, 2019, 148: 119068. |

| 55 | Fang G, Tang F, Cao L. Preparation, thermal properties and applications of shape-stabilized thermal energy storage materials[J]. Renewable and Sustainable Energy Reviews, 2014, 40: 237-259. |

| 56 | Kenisarin M M, Kenisarina K M. Form-stable phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2012, 16(4): 1999-2040. |

| 57 | Liu C, Xu Z, Song Y, et al. A novel shape-stabilization strategy for phase change thermal energy storage[J]. Journal of Materials Chemistry A, 2019, 7(14): 8194-8203. |

| 58 | Liu C, Ma X, Du P, et al. Fabrication of highly efficient thermal energy storage composite from waste polystyrenes[J]. Chemical Engineering Science, 2020, 216: 115477. |

| 59 | Gatti G, Errahali M, Tei L, et al. A porous carbon with excellent gas storage properties from waste polystyrene[J]. Nanomaterials, 2019, 9(5): 726. |

| 60 | Wang X, Wang G, Marchetti A, et al. Preparation of porous hydroxyapatite and its application in Pb ions effective removal[J]. AIP Advances, 2019, 9(2): 025123. |

| 61 | Cao J, Wang Y, Yan Z, et al. Polystyrene microspheres-templated preparation of hierarchical porous modified red mud with high rhodamine B dye adsorption performance[J]. Micro & Nano Letters, 2014, 9(4): 229-231. |

| 62 | You C, Liao S, Qiao X, et al. Conversion of polystyrene foam to a high-performance doped carbon catalyst with ultrahigh surface area and hierarchical porous structures for oxygen reduction[J]. Journal of Materials Chemistry A,2014, 2(31): 12240-12246. |

| 63 | Wu Z, Kong L, Hu H, et al. Adsorption performance of hollow spherical sludge carbon prepared from sewage sludge and polystyrene foam wastes[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(3): 552-558. |

| 64 | Moharir P V, Tembhurkar A R. Comparative performance evaluation of novel polystyrene membrane with ultrex as proton exchange membranes in microbial fuel cell for bioelectricity production from food waste[J]. Bioresource Technology, 2018, 266: 291-296. |

| 65 | Min J, Zhang S, Li J, et al. From polystyrene waste to porous carbon flake and potential application in supercapacitor[J]. Waste Management, 2019, 85: 333-340. |

| 66 | Ma C, Liu X, Min J, et al. Sustainable recycling of waste polystyrene into hierarchical porous carbon nanosheets with potential applications in supercapacitors[J]. Nanotechnology, 2020, 31(3): 035402. |

| 67 | Zhang Y, Shen Z, Yu Y, et al. Porous carbon derived from waste polystyrene foam for supercapacitor[J]. Journal of Materials Science, 2018, 53(17): 12115-12122. |

| 68 | Fonseca W S, Meng X, Deng D. Trash to treasure: transforming waste polystyrene cups into negative electrode materials for sodium ion batteries[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(9): 2153-2159. |

| 69 | Veziroglu T N, Sahin S. 21st century s energy: hydrogen energy system[J]. Energy Conversion and Management, 2008, 49(7): 1820-1831. |

| 70 | Maniyali Y, Almansoori A, Fowler M, et al. Energy hub based on nuclear energy and hydrogen energy storage[J]. Industrial & Engineering Chemistry Research, 2013, 52(22): 7470-7481. |

| 71 | Kojima Y. Hydrogen storage materials for hydrogen and energy carriers[J]. International Journal of Hydrogen Energy, 2019, 44(33): 18179-18192. |

| 72 | Zhou X, Zhou J, Lue K, et al. Tripyrrylmethane based 2D porous structure for hydrogen storage[J]. Frontiers of Physics, 2011, 6(2): 220-223. |

| 73 | Sevilla M, Mokaya R. Energy storage applications of activated carbons: supercapacitors and hydrogen storage[J]. Energy & Environmental Science, 2014, 7(4): 1250-1280. |

| 74 | Li Y, Fu Z Y, Su B L. Hierarchically structured porous materials for energy conversion and storage[J]. Advanced Functional Materials, 2012, 22(22): 4634-4667. |

| 75 | Gong J, Michalkiewicz B, Chen X, et al. Sustainable conversion of mixed plastics into porous carbon nanosheets with high performances in uptake of carbon dioxide and storage of hydrogen[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(12): 2837-2844. |

| 76 | Gong J, Chen X, Tang T. Recent progress in controlled carbonization of (waste) polymers[J]. Progress in Polymer Science, 2019, 94: 1-32. |

| 77 | Damodharan D, Rajesh Kumar B, Gopal K, et al. Utilization of waste plastic oil in diesel engines: a review[J]. Reviews in Environmental Science and Bio/Technology, 2019, 18(4): 681-697. |

| 78 | Kuzhiyil N, Kong S C. Energy recovery from waste plastics by using blends of biodiesel and polystyrene in diesel engines[J]. Energy & Fuels, 2009, 23(6): 3246-3253. |

| 79 | Kiran N, Ekinci E, Snape C E. Recyling of plastic wastes via pyrolysis[J]. Resources, Conservation and Recycling, 2000, 29(4): 273-283. |

| 80 | Fuentes-Ordonez E G, Salbidegoitia J A, Gonzalez-Marcos M P, et al. Mechanism and kinetics in catalytic hydrocracking of polystyrene in solution[J]. Polymer Degradation and Stability, 2016, 124: 51-59. |

| 81 | Vaziri H S, Abadyan M, Nouri M, et al. Investigation of the fracture mechanism and mechanical properties of polystyrene/silica nanocomposite in various silica contents[J]. Journal of Materials Science, 2011, 46(17): 5628-5638. |

| 82 | 张翔, 宋修艳, 刘福胜. 介孔分子筛催化裂解聚合物材料的研究进展[J]. 化工科技, 2017, 25(2): 53-56. |

| Zhang X, Song X Y, Liu F S. Progress in mesoporous molecular sieves catalytic cracking of polymer materials[J], Science and Technology in Chemical Industry, 2017, 25(2): 53-56. | |

| 83 | Artetxe M, Lopez G, Amutio M, et al. Styrene recovery from polystyrene by flash pyrolysis in a conical spouted bed reactor[J]. Waste Management, 2015, 45: 126-133. |

| 84 | Filip M, Pop A, Perhaiţa I, et al. Investigation of thermal and catalytic degradation of polystyrene waste into styrene monomer over natural volcanic tuff and Florisil catalysts[J]. Central European Journal of Chemistry, 2013, 11(5): 725-735. |

| 85 | Ruan J, Dong L, Huang J, et al. Vacuum-gasification-condensation of waste toner to produce industrial chemicals and nanomaterials[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(6): 4923-4929. |

| 86 | Ruan J, Jia L, Xu Z. Improvements of the recovery line of waste toner cartridges on environmental and safety performances[J]. Environmental Science and Technology, 2013, 47(12): 6457-6462. |

| 87 | Ruan J, Xu Z. Approaches to improve separation efficiency of eddy current separation for recovering aluminum from waste toner cartridges[J]. Environmental Science and Technology, 2012, 46(11): 6214-6221. |

| 88 | Hadi B, Sokoto A M, Garba M M, et al. Effect of neat kaolin and CuO/kaolin on the yield and composition of products from pyrolysis of polystyrene waste[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2017, 39(2): 148-153. |

| 89 | Sanahuja-Parejo O, Veses A, Navarro M V, et al. Drop-in biofuels from the co-pyrolysis of grape seeds and polystyrene[J]. Chemical Engineering Journal, 2019, 377: 120246. |

| 90 | Shadangi K P, Mohanty K. Co-pyrolysis of Karanja and Niger seeds with waste polystyrene to produce liquid fuel[J]. Fuel, 2015, 153: 492-498. |

| 91 | Nisar J, Ali G, Shah A, et al. Fuel production from waste polystyrene via pyrolysis: kinetics and products distribution[J]. Waste Management, 2019, 88: 236-247. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [4] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [5] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [6] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [7] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [8] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [9] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [10] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [11] | 陈吉, 洪泽, 雷昭, 凌强, 赵志刚, 彭陈辉, 崔平. 基于分子动力学的焦炭溶损反应及其机理研究[J]. 化工学报, 2023, 74(7): 2935-2946. |

| [12] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [13] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [14] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [15] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号