化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3659-3668.DOI: 10.11949/0438-1157.20220523

崔敬泽( ), 汤琼, 陈晨, 刘宇婕, 徐红, 刘雷(

), 汤琼, 陈晨, 刘宇婕, 徐红, 刘雷( ), 董晋湘

), 董晋湘

收稿日期:2022-04-11

修回日期:2022-05-02

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

刘雷

作者简介:崔敬泽(1997—),男,硕士研究生,515309165@qq.com

基金资助:

Jingze CUI( ), Qiong TANG, Chen CHEN, Yujie LIU, Hong XU, Lei LIU(

), Qiong TANG, Chen CHEN, Yujie LIU, Hong XU, Lei LIU( ), Jinxiang DONG

), Jinxiang DONG

Received:2022-04-11

Revised:2022-05-02

Online:2022-08-05

Published:2022-09-06

Contact:

Lei LIU

摘要:

目前润滑基础油主要来源于石油资源,基于我国富煤贫油的现状,开发煤基原料合成润滑基础油的工艺路线具有重要意义。以煤化工过程产生的多环芳烃(苊)和烯烃为原料,以离子液体([Et3NH][Al2Cl7])为催化剂通过烷基化反应探索了高黏度润滑基础油的合成。通过调控烯烃(己烯或辛烯)和苊的反应比例,合成了四种不同组成和结构的多烷基苊基础油,通过GC和GC-MS对其成分进行了分析。对不同油品的物化性能指标进行表征,揭示了产物组成结构和性质的关系,烷基苊基础油具有高的黏度(10.1~19.5 mm2·s-1,100℃)、苯胺点(<63℃)和起始氧化温度(>190℃);同时,烷基苊作为润滑基础油表现出优良的摩擦学性能,且随着苊环侧链烷基化程度的增加,其抗载荷能力会增强。

中图分类号:

崔敬泽, 汤琼, 陈晨, 刘宇婕, 徐红, 刘雷, 董晋湘. 高黏度烷基苊基础油的合成及润滑性能研究[J]. 化工学报, 2022, 73(8): 3659-3668.

Jingze CUI, Qiong TANG, Chen CHEN, Yujie LIU, Hong XU, Lei LIU, Jinxiang DONG. Synthesis of high viscosity alkylated acenaphthene and investigation of their lubrication property[J]. CIESC Journal, 2022, 73(8): 3659-3668.

| 样品名称 | 烯烃/苊 (摩尔比) | 产物分布/% | |||

|---|---|---|---|---|---|

单烷 基苊 | 二烷 基苊 | 三烷 基苊 | 四烷 基苊 | ||

| 己基苊-2 | 2/1 | 22.60 | 54.50 | 22.39 | 0.51 |

| 己基苊-3 | 3/1 | 3.55 | 31.48 | 58.37 | 6.59 |

| 辛基苊-2 | 2/1 | 25.08 | 46.27 | 28.00 | 0.64 |

| 辛基苊-3 | 3/1 | 7.17 | 38.10 | 50.51 | 4.22 |

表1 己基苊和辛基苊的产物分布

Table 1 Product distribution of hexylacenaphthene and octylacenaphthene

| 样品名称 | 烯烃/苊 (摩尔比) | 产物分布/% | |||

|---|---|---|---|---|---|

单烷 基苊 | 二烷 基苊 | 三烷 基苊 | 四烷 基苊 | ||

| 己基苊-2 | 2/1 | 22.60 | 54.50 | 22.39 | 0.51 |

| 己基苊-3 | 3/1 | 3.55 | 31.48 | 58.37 | 6.59 |

| 辛基苊-2 | 2/1 | 25.08 | 46.27 | 28.00 | 0.64 |

| 辛基苊-3 | 3/1 | 7.17 | 38.10 | 50.51 | 4.22 |

| 产品名称 | 密度/ (g·cm-3) | 运动黏度/(mm2·s-1) | 黏度指数 | 苯胺点/℃ | 倾点/℃ | 闪点/℃ | 起始氧化温度/℃ | |

|---|---|---|---|---|---|---|---|---|

| 40℃ | 100℃ | |||||||

| 己基苊-2 | 0.9534 | 171.9 | 10.1 | — | 15.2 | -18 | 201 | 192 |

| 己基苊-3 | 0.9343 | 349.6 | 15.4 | — | 34.5 | -16 | 208 | 198 |

| 辛基苊-2 | 0.9372 | 190.5 | 12.5 | 24 | 38.5 | -23 | 219 | 201 |

| 辛基苊-3 | 0.9186 | 331.6 | 19.5 | 52 | 62.4 | -19 | 236 | 205 |

表2 烷基苊产物的基本物化性质

Table 2 Physicochemical properties of alkylated acenaphthenes

| 产品名称 | 密度/ (g·cm-3) | 运动黏度/(mm2·s-1) | 黏度指数 | 苯胺点/℃ | 倾点/℃ | 闪点/℃ | 起始氧化温度/℃ | |

|---|---|---|---|---|---|---|---|---|

| 40℃ | 100℃ | |||||||

| 己基苊-2 | 0.9534 | 171.9 | 10.1 | — | 15.2 | -18 | 201 | 192 |

| 己基苊-3 | 0.9343 | 349.6 | 15.4 | — | 34.5 | -16 | 208 | 198 |

| 辛基苊-2 | 0.9372 | 190.5 | 12.5 | 24 | 38.5 | -23 | 219 | 201 |

| 辛基苊-3 | 0.9186 | 331.6 | 19.5 | 52 | 62.4 | -19 | 236 | 205 |

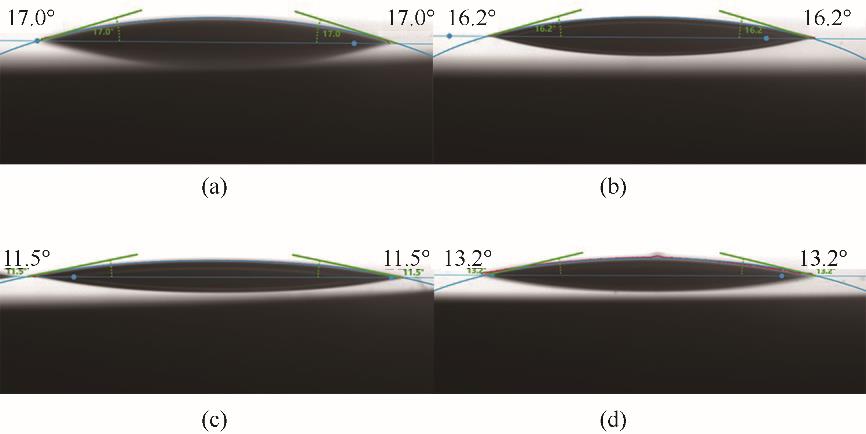

图5 己基苊-2(a)、己基苊-3(b)、辛基苊-2(c)和辛基苊-3(d)在钢盘上的接触角

Fig.5 Contact angle of hexylacenaphthene-2 (a), hexylacenaphthene-3 (b), octylacenaphthene-2 (c) and octylacenaphthene-3 (d) on steel disc

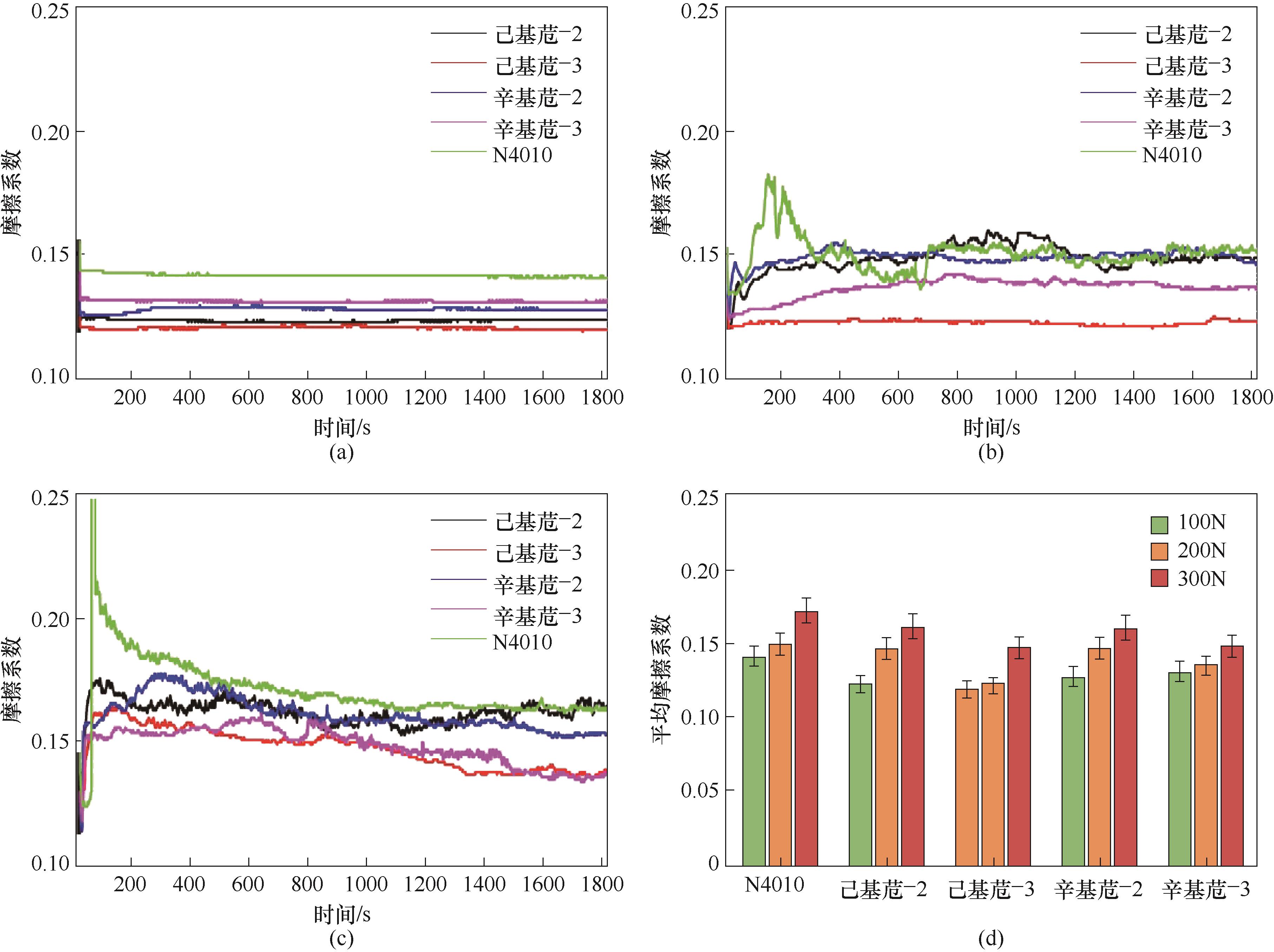

图7 在100 N(a)、200 N(b)和300 N(c)载荷下的摩擦曲线和平均摩擦系数(d)

Fig.7 Friction curves under the load of 100 N (a), 200 N (b) and 300 N (c) and average friction coefficient (d)

| 1 | Holmberg K, Erdemir A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars[J]. Tribology International, 2019, 135: 389-396. |

| 2 | Holmberg K, Erdemir A. Influence of tribology on global energy consumption, costs and emissions[J]. Friction, 2017, 5(3): 263-284. |

| 3 | Fan M J, Ai J, Hu C H, et al. Naphthoate based lubricating oil with high oxidation stability and lubricity[J]. Tribology International, 2019, 138: 204-210. |

| 4 | Liu S B, Bhattacharjee R, Li S, et al. Thiol-promoted catalytic synthesis of high-performance furan-containing lubricant base oils from biomass derived 2-alkylfurans and ketones[J]. Green Chemistry, 2020, 22(22): 7896-7906. |

| 5 | Fox I E. Numerical evaluation of the potential for fuel economy improvement due to boundary friction reduction within heavy-duty diesel engines[J]. Tribology International, 2005, 38(3): 265-275. |

| 6 | Hu S J, Zhu J H, Wu B C, et al. Green synthesis of ester base oil with high viscosity(Ⅰ): Catalyst preparation, characterization, evaluation, and mechanism analysis[J]. Fuel, 2020, 274: 117802. |

| 7 | Jiang H B, Xu X L, Hong X Z, et al. Preparation of high viscosity PAO from mixed alpha-olefins over metallocene catalyst[J]. China Petroleum Processing & Petrochemical Technology, 2018, 20(2): 90-96. |

| 8 | Hu S J, Zhu J H, Wu B C, et al. Green synthesis of ester base oil with high viscosity(Ⅱ): Reaction kinetics study[J]. Chemical Engineering Research and Design, 2021, 165: 51-60. |

| 9 | Li L, Zhao X R, Chen C, et al. Highly selective synthesis of polyalkylated naphthalenes catalyzed by ionic liquids and their tribological properties as lubricant base oil[J]. ChemistrySelect, 2019, 4(18): 5284-5290. |

| 10 | Chen C, Tang Q, Xu H, et al. Alkylation of naphthalene with n-butene catalyzed by liquid coordination complexes and its lubricating properties[J]. Chinese Journal of Chemical Engineering, 2021, 39: 306-313. |

| 11 | Nagendramma P, Kaul S. Development of ecofriendly/biodegradable lubricants: an overview[J]. Renewable and Sustainable Energy Reviews, 2012, 16(1): 764-774. |

| 12 | Yang T, Wang F J, Huang J P, et al. Efficient continuous-flow synthesis of long-chain alkylated naphthalene catalyzed by ionic liquids in a microreaction system[J]. Reaction Chemistry & Engineering, 2021, 6(10): 1950-1960. |

| 13 | Granda M, Blanco C, Alvarez P, et al. Chemicals from coal coking[J]. Chemical Reviews, 2014, 114(3): 1608-1636. |

| 14 | 谷小会. 煤焦油分离方法及组分性质研究现状与展望[J]. 洁净煤技术, 2018, 24(4): 1-6, 12. |

| Gu X H. Status and prospect of separation methods and composition characteristics of coal tar[J]. Clean Coal Technology, 2018, 24(4): 1-6, 12. | |

| 15 | Ma Z H, Wei X Y, Liu G H, et al. Value-added utilization of high-temperature coal tar: a review[J]. Fuel, 2021, 292: 119954. |

| 16 | 汪廷贵, 张乐涛, 蔡国星, 等. 一种烷基萘基础油的合成及润滑性能研究[J]. 石油炼制与化工, 2013, 44(11): 96-99. |

| Wang T G, Zhang L T, Cai G X, et al. Study on synthesis of alkyl naphthalene base oils and their lubricating properties[J]. Petroleum Processing and Petrochemicals, 2013, 44(11): 96-99. | |

| 17 | 刘雷, 陈晨, 李磊, 等. 一种利用离子液体催化制备多烷基萘的方法及其应用: 109824467A[P]. 2019-05-31. |

| Liu L, Chen C, Li L, et al. Method for preparing polyalkylnaphthalene through catalysis of ionic liquid and application of method: 109824467A[P]. 2019-05-31. | |

| 18 | Peters A T. Acenaphthene series(Ⅰ): Mono- and di-tert.-butyl-acenaphthene, -acenaphthenequinone, and -naphthalic anhydride, and their derivatives[J]. Journal of the Chemical Society (Resumed), 1942: 562-565. |

| 19 | Nürsten H E, Peters A T. Acenaphthene series(Ⅲ): Orientation of tert.-butyl- and di-tert.-butyl-acenaphthene, and preparation of new derivatives[J]. Journal of the Chemical Society(Resumed), 1950: 729-736. |

| 20 | Illingworth E, Peters A T. Acenaphthene series(Ⅶ): The three isomeric tert.-butylacenaphthenes. Migration of tert.-butyl groups and disproportionation. Preparation and orientation of 1,3,6-tri-tert.-butylacenaphthene[J]. Journal of the Chemical Society (Resumed), 1952: 2730-2735. |

| 21 | Peters A T. Mechanisms of reactions in the acenaphthene series. Migration of t-butyl, and disproportionate[J]. Nature, 1965, 205(4967): 170-171. |

| 22 | Mock W L, Tsao L I. Isopropylation of acenaphthene[J]. Synthetic Communications, 1991, 21(3): 371-378. |

| 23 | Chen S, Wu T T, Zhao C. Conversion of lipid into high-viscosity branched bio-lubricant base oil[J]. Green Chemistry, 2020, 22(21): 7348-7354. |

| 24 | Covitch M J, Trickett K J. How polymers behave as viscosity index improvers in lubricating oils[J]. Advances in Chemical Engineering and Science, 2015, 5(2): 134-151. |

| 25 | Martini A, Ramasamy U S, Len M. Review of viscosity modifier lubricant additives[J]. Tribology Letters, 2018, 66(2): 1-14. |

| 26 | Fan M J, Zhang C Y, Wen P, et al. High-performance lubricant base stocks from biorenewable Gallic acid: systematic study on their physicochemical and tribological properties[J]. Industrial & Engineering Chemistry Research, 2017, 56(34): 9513-9523. |

| 27 | Zhmud B. Beyond the aniline point: critical solution point for the oil/aniline system as a measure of oil solubility[J]. Fuel, 2007, 86(16): 2545-2550. |

| 28 | Elhamarnah Y A, Nasser M, Qiblawey H, et al. A comprehensive review on the rheological behavior of imidazolium based ionic liquids and natural deep eutectic solvents[J]. Journal of Molecular Liquids, 2019, 277: 932-958. |

| 29 | Zhou S Q, Ni R, Funfschilling D. Effects of shear rate and temperature on viscosity of alumina polyalphaolefins nanofluids[J]. Journal of Applied Physics, 2010, 107(5): 054317. |

| 30 | Kerni L, Raina A, Haq M I U. Friction and wear performance of olive oil containing nanoparticles in boundary and mixed lubrication regimes[J]. Wear, 2019, 426/427: 819-827. |

| 31 | Liu X X, Li Q, Gao X X, et al. The palm oil-based microemulsion: fabrication, characterization and rheological properties[J]. Journal of Molecular Liquids, 2020, 302: 112527. |

| 32 | Jiang D, Hu L T, Feng D P. Crown-type ionic liquids as lubricants for steel-on-steel system[J]. Tribology Letters, 2011, 41(2): 417-424. |

| 33 | Mendonça A C F, Malfreyt P, Pádua A A H. Interactions and ordering of ionic liquids at a metal surface[J]. Journal of Chemical Theory and Computation, 2012, 8(9): 3348-3355. |

| 34 | Yu Q L, Zhang C Y, Dong R, et al. Physicochemical and tribological properties of gemini-type halogen-free dicationic ionic liquids[J]. Friction, 2021, 9(2): 344-355. |

| 35 | Guo Y X, Qiao D, Han Y Y, et al. Application of alkylphosphate ionic liquids as lubricants for ceramic material[J]. Industrial & Engineering Chemistry Research, 2015, 54(51): 12813-12825. |

| [1] | 吴曦, 区祖迪, 张鑫杰, 徐士鸣, 朱晓静. HFO-1243zf爆燃特性实验研究[J]. 化工学报, 2023, 74(S1): 346-352. |

| [2] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [3] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [4] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [5] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [6] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [7] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [8] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [9] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [10] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [11] | 王俐智, 杭钱程, 郑叶玲, 丁延, 陈家继, 叶青, 李进龙. 离子液体萃取剂萃取精馏分离丙酸甲酯+甲醇共沸物[J]. 化工学报, 2023, 74(9): 3731-3741. |

| [12] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [13] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [14] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [15] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号