化工学报 ›› 2021, Vol. 72 ›› Issue (12): 6049-6061.DOI: 10.11949/0438-1157.20211075

收稿日期:2021-08-02

修回日期:2021-10-14

出版日期:2021-12-05

发布日期:2021-12-22

通讯作者:

程芳琴

作者简介:许文娇(1994—),女,博士研究生,基金资助:

Wenjiao XU( ),Huaigang CHENG,Fangqin CHENG(

),Huaigang CHENG,Fangqin CHENG( )

)

Received:2021-08-02

Revised:2021-10-14

Online:2021-12-05

Published:2021-12-22

Contact:

Fangqin CHENG

摘要:

化工燃料在提供能源过程中产生的低浓度CO2废气可以被工业废液吸收。结合当前研究现状,介绍了用工业废液吸收低浓度CO2废气的研究进展,并开展了可行性分析;归纳了CO2废气与工业废液的反应原理,将其大致分为中和反应、复分解反应、微生物转化等反应类型,并讨论了其吸收动力学;总结了工业废液吸收低浓度CO2废气的工艺装置与流程。在废液吸收废气的处理模式中,CO2的吸收对降低碱液的pH、脱除废液中有害物质效果良好,同时还可以副产微纳米碳酸钙、生物柴油等高附加值产品,实现废弃资源的深度循环利用。此外,分析了工业废液吸收CO2废气的生命周期评价,通过对能耗、碳排放和成本评估,进一步讨论了工业废液吸收CO2废气对环境的影响及经济可行性。结合CO2减排的前景,从工业应用的角度探讨了工业废液用作低浓度CO2吸收剂面临的挑战,并对其未来产业化发展进行了展望。

中图分类号:

许文娇, 成怀刚, 程芳琴. 工业废液吸收低浓度CO2:可行性及应用[J]. 化工学报, 2021, 72(12): 6049-6061.

Wenjiao XU, Huaigang CHENG, Fangqin CHENG. Absorption of low-concentration CO2 by industrial effluents: feasibility and application[J]. CIESC Journal, 2021, 72(12): 6049-6061.

| 工业废液 | 主要成分 | 实例 | |||

|---|---|---|---|---|---|

| 碱性废液 | 碱液 | OH- | 纺织工业的碱性废液[ 工业生产1,4-丁二醇脱离子工段碱性废液[ | ||

| 含钙废液 | 含钙碱液 | OH-、Ca2+、Mg2+ | 钢渣堆固废沥滤处理产生的碱性废液[ 工业生产牛皮纸浆产生的含钙污水泥浆[ 电厂粉煤灰沥滤废液[ 工业固废磷石膏沥滤处理产生工业废液[ 混凝土工业产生碱性废液[ 工业电石渣废液上清液[ 皮革厂产生的浸灰泥浆废水[ 水泥窑粉尘悬浊废液[ 城市垃圾焚烧底灰[ 电厂油页岩灰产生的工业废液[ | ||

| 钙液 | Ca2+、醇胺吸收剂(外加) | 盐业公司生产的工业废液[ 海水工业废液[ | |||

| 微生物可转化废液 | 微生物可转化钙液 | Ca2+、NO | 炼钢厂排放的废水[ 制革污水 [ 木浆造纸工业废水[ | ||

| 微生物可转化废液 | NO | 炼油污水 [ 地毯厂废水 [ 牛奶加工废水[ | |||

表1 吸收CO2的工业废液分类、主要成分及实例

Table 1 Classification, main components and examples of industrial waste water that can absorb CO2

| 工业废液 | 主要成分 | 实例 | |||

|---|---|---|---|---|---|

| 碱性废液 | 碱液 | OH- | 纺织工业的碱性废液[ 工业生产1,4-丁二醇脱离子工段碱性废液[ | ||

| 含钙废液 | 含钙碱液 | OH-、Ca2+、Mg2+ | 钢渣堆固废沥滤处理产生的碱性废液[ 工业生产牛皮纸浆产生的含钙污水泥浆[ 电厂粉煤灰沥滤废液[ 工业固废磷石膏沥滤处理产生工业废液[ 混凝土工业产生碱性废液[ 工业电石渣废液上清液[ 皮革厂产生的浸灰泥浆废水[ 水泥窑粉尘悬浊废液[ 城市垃圾焚烧底灰[ 电厂油页岩灰产生的工业废液[ | ||

| 钙液 | Ca2+、醇胺吸收剂(外加) | 盐业公司生产的工业废液[ 海水工业废液[ | |||

| 微生物可转化废液 | 微生物可转化钙液 | Ca2+、NO | 炼钢厂排放的废水[ 制革污水 [ 木浆造纸工业废水[ | ||

| 微生物可转化废液 | NO | 炼油污水 [ 地毯厂废水 [ 牛奶加工废水[ | |||

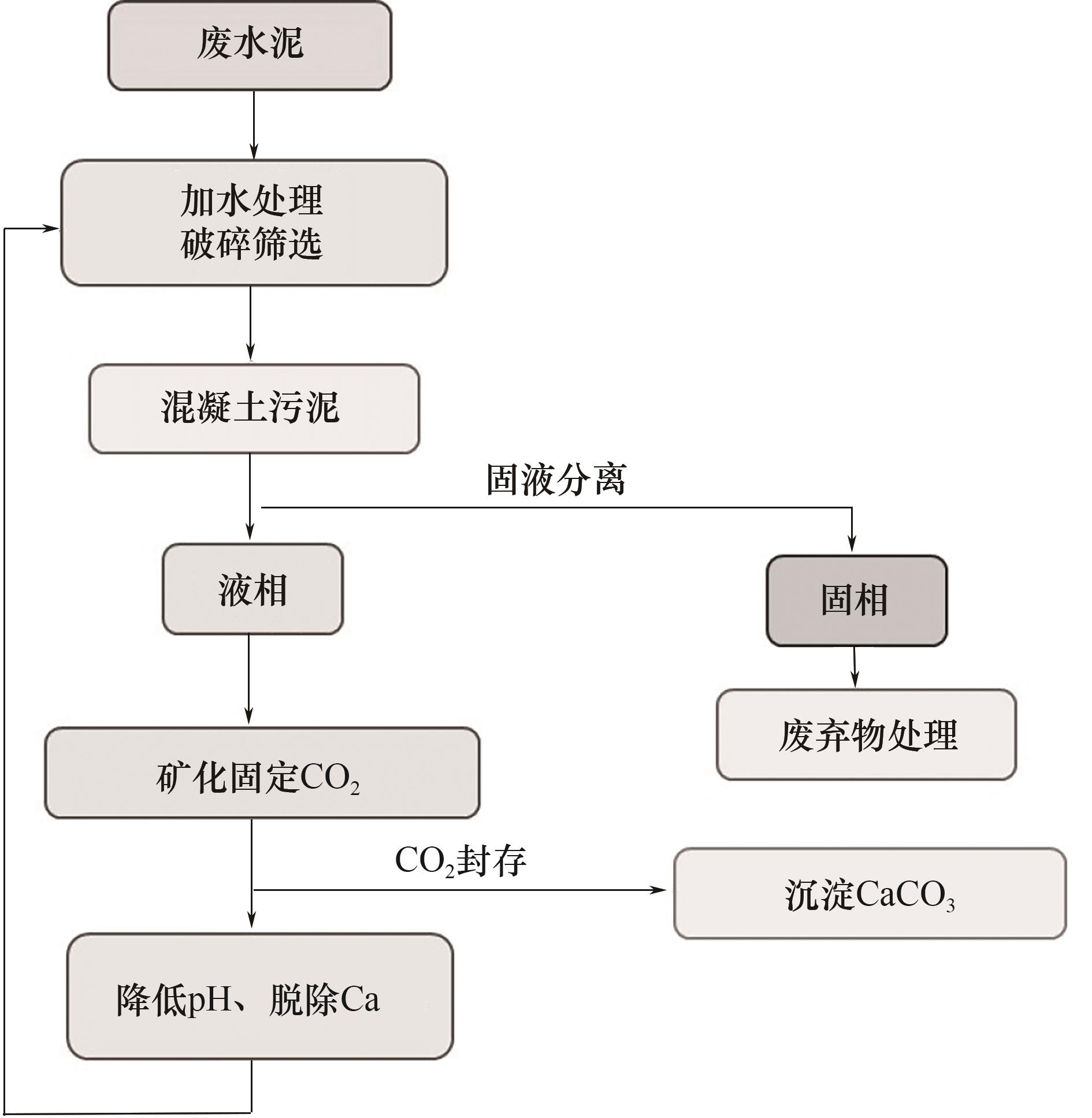

图5 用CO2中和废混凝土回收工艺中富钙碱性废水的工艺流程示意图

Fig.5 Schematic diagram of the process flow of CO2 neutralization of calcium-rich alkaline wastewater in the recycling process of waste concrete

| 1 | Wang J Y, Huang L, Yang R Y, et al. Recent advances in solid sorbents for CO2 capture and new development trends[J]. Energy & Environmental Science, 2014, 7(11): 3478-3518. |

| 2 | Sanz-Pérez E S, Murdock C R, Didas S A, et al. Direct capture of CO2 from ambient air[J]. Chemical Reviews, 2016, 116(19): 11840-11876. |

| 3 | Zhang L, Zhao Z J, Gong J L. Nanostructured materials for heterogeneous electrocatalytic CO2 reduction and their related reaction mechanisms[J]. Angewandte Chemie International Edition, 2017, 56(38): 11326-11353. |

| 4 | 林海周, 罗海中, 裴爱国, 等. 燃煤电厂烟气MDEA/PZ混合胺法碳捕集工艺模拟分析[J]. 化工进展, 2019, 38(4): 2046-2055. |

| Lin H Z, Luo H Z, Pei A G, et al. Simulation and analysis of carbon dioxide capture process using MDEA/PZ blend solution in a coal-fired power plant[J]. Chemical Industry and Engineering Progress, 2019, 38(4): 2046-2055. | |

| 5 | Hamouda A S, Eldien M S, Abadir M F. Carbon dioxide capture by ammonium hydroxide solution and its possible application in cement industry[J]. Ain Shams Engineering Journal, 2020, 11(4): 1061-1067. |

| 6 | Ma'mun S. Amino-acid-salt-based carbon dioxide capture: precipitation behavior of potassium sarcosine solution[J]. IOP Conference Series: Materials Science and Engineering, 2020, 811: 012033. |

| 7 | Zhan X H, Lv B, Yang K X, et al. Dual-functionalized ionic liquid biphasic solvent for carbon dioxide capture: high-efficiency and energy saving[J]. Environmental Science & Technology, 2020, 54(10): 6281-6288. |

| 8 | Lombardo L, Yang H, Zhao K, et al. Solvent- and catalyst-free carbon dioxide capture and reduction to formate with borohydride ionic liquid[J]. ChemSusChem, 2020, 13(8): 2025-2031. |

| 9 | Ding M, Flaig R W, Jiang H L, et al. Carbon capture and conversion using metal-organic frameworks and MOF-based materials[J]. Chemical Society Reviews, 2019, 48(10): 2783-2828. |

| 10 | Khan J, Iqbal N, Asghar A, et al. Novel amine functionalized metal organic framework synthesis for enhanced carbon dioxide capture[J]. Materials Research Express, 2019, 6(10): 105539. |

| 11 | Valverde J M. Ca-based synthetic materials with enhanced CO2 capture efficiency[J]. Journal of Materials Chemistry A, 2013, 1(3): 447-468. |

| 12 | Mosaffa A H, Farshi L G. Novel post combustion CO2 capture in the coal-fired power plant employing a transcritical CO2 power generation and low temperature steam upgraded by an absorption heat transformer[J]. Energy Conversion and Management, 2020, 207: 112542. |

| 13 | Iasimone F, De Felice V, Panico A, et al. Experimental study for the reduction of CO2 emissions in wastewater treatment plant using microalgal cultivation[J]. Journal of CO2 Utilization, 2017, 22: 1-8. |

| 14 | Gaur A, Park J W, Jang J H, et al. Characteristics of alkaline wastewater neutralization for CO2 capture from landfill gas (LFG)[J]. Energy & Fuels, 2009, 23(11): 5467-5473. |

| 15 | Bove P, Claveau-Mallet D, Boutet É, et al. Development and modelling of a steel slag filter effluent neutralization process with CO2-enriched air from an upstream bioprocess[J]. Water Research, 2018, 129: 11-19. |

| 16 | Ferreira A, Ribeiro B, Marques P A S S, et al. Scenedesmus obliquus mediated brewery wastewater remediation and CO2 biofixation for green energy purposes[J]. Journal of Cleaner Production, 2017, 165: 1316-1327. |

| 17 | Mayes W M, Younger P L, Aumônier J. Buffering of alkaline steel slag leachate across a natural wetland[J]. Environmental Science & Technology, 2006, 40(4): 1237-1243. |

| 18 | Yang L, Liu S, Yu L. Removing CO2 and H2S from the gas produced during underground coal gasification (UCG)[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2007, 29(10): 915-929. |

| 19 | Kim I, Yoo Y, Son J, et al. Two-step mineral carbonation using seawater-based industrial wastewater: an eco-friendly carbon capture, utilization, and storage process[J]. Journal of Material Cycles and Waste Management, 2020, 22(2): 333-347. |

| 20 | Yoo Y, Kang D, Kim I, et al. Characteristics of metal cation carbonation and carbon dioxide utilization using seawater-based industrial wastewater[J]. ChemistrySelect, 2018, 3(32): 9284-9292. |

| 21 | Kang D, Yoo Y, Park J, et al. Chemical conversion of carbon dioxide via target metal separation using seawater-derived wastewater[J]. ChemistrySelect, 2018, 3(30): 8628-8636. |

| 22 | Dindi A, Quang D V, Abu-Zahra M R M. Simultaneous carbon dioxide capture and utilization using thermal desalination reject brine[J]. Applied Energy, 2015, 154: 298-308. |

| 23 | Najib M Z M, Salmiati, Ujang Z, et al. Reduction and biofixation of carbon dioxide in palm oil mill effluent using developed microbial granules containing photosynthetic pigments[J]. Bioresource Technology, 2016, 221: 157-164. |

| 24 | Alamdari A, Alamdari A, Mowla D. Kinetics of calcium carbonate precipitation through CO2 absorption from flue gas into distiller waste of soda ash plant[J]. Journal of Industrial and Engineering Chemistry, 2014, 20(5): 3480-3486. |

| 25 | Ferreira Filho E A, Chui Q S H. Qualidade de medições e neutralização de efluentes alcalinos com dióxido de carbono[J]. Engenharia Sanitaria e Ambiental, 2006, 11(2): 169-174. |

| 26 | Pérez-López R, Castillo J, Quispe D, et al. Neutralization of acid mine drainage using the final product from CO2 emissions capture with alkaline paper mill waste[J]. Journal of Hazardous Materials, 2010, 177(1/2/3): 762-772. |

| 27 | 董良宇, 曹鹏. 碱性工业废水吸收二氧化碳调节pH值的研究[J]. 广东化工, 2019, 46(20): 12-14. |

| Dong L Y, Cao P. Study on pH adjustment of alkaline industrial wastewater by absorbing carbon dioxide[J]. Guangdong Chemical Industry, 2019, 46(20): 12-14. | |

| 28 | Cárdenas-Escudero C, Morales-Flórez V, Pérez-López R, et al. Procedure to use phosphogypsum industrial waste for mineral CO2 sequestration[J]. Journal of Hazardous Materials, 2011, 196: 431-435. |

| 29 | Kang D, Lee M G, Jo H, et al. Carbon capture and utilization using industrial wastewater under ambient conditions[J]. Chemical Engineering Journal, 2017, 308: 1073-1080. |

| 30 | Eloneva S, Teir S, Salminen J, et al. Fixation of CO2 by carbonating calcium derived from blast furnace slag[J]. Energy, 2008, 33(9): 1461-1467. |

| 31 | 王晓龙, 万超然, 郜时旺, 等. 粉煤灰CO2矿化利用溶出实验[J]. 电力建设, 2014, 35(7): 58-62. |

| Wang X L, Wan C R, Gao S W, et al. Dissolution test on CO2 mineralization by fly ash[J]. Electric Power Construction, 2014, 35(7): 58-62. | |

| 32 | Sun Y, Yao M S, Zhang J P, et al. Indirect CO2 mineral sequestration by steelmaking slag with NH4Cl as leaching solution[J]. Chemical Engineering Journal, 2011, 173(2): 437-445. |

| 33 | Judd S, van den Broeke L J P, Shurair M, et al. Algal remediation of CO2 and nutrient discharges: a review[J]. Water Research, 2015, 87: 356-366. |

| 34 | Yoo J, Shin H, Ji S. An eco-friendly neutralization process by carbon mineralization for Ca-rich alkaline wastewater generated from concrete sludge[J]. Metals, 2017, 7(9): 371. |

| 35 | 帅欢, 王丽娟, 李男, 等. 电石渣制备纳米碳酸钙中浸出与碳化工艺研究[J]. 非金属矿, 2018, 41(5): 4-6. |

| Shuai H, Wang L J, Li N, et al. Study on leaching and carbonization process of preparation of nano calcium carbonate from calcium carbide slag[J]. Non-Metallic Mines, 2018, 41(5): 4-6. | |

| 36 | Ecke H, Menad N, Lagerkvist A. Carbonation of municipal solid waste incineration fly ash and the impact on metal mobility[J]. Journal of Environmental Engineering, 2003, 129(5): 435-440. |

| 37 | Venkatakrishnan B, Sandhya K V, Abinandan S, et al. Fixation of carbon dioxide and optimization of liming process waste produced in tanneries using response surface methodology[J]. Journal of Cleaner Production, 2019, 209: 855-861. |

| 38 | Huntzinger D N, Gierke J S, Sutter L L, et al. Mineral carbonation for carbon sequestration in cement kiln dust from waste piles[J]. Journal of Hazardous Materials, 2009, 168(1): 31-37. |

| 39 | Arickx S, van Gerven T, Vandecasteele C. Accelerated carbonation for treatment of MSWI bottom ash[J]. Journal of Hazardous Materials, 2006, 137(1): 235-243. |

| 40 | Uibu M, Uus M, Kuusik R. CO2 mineral sequestration in oil-shale wastes from Estonian power production[J]. Journal of Environmental Management, 2009, 90(2): 1253-1260. |

| 41 | Noack C W, Dzombak D A, Nakles D V, et al. Comparison of alkaline industrial wastes for aqueous mineral carbon sequestration through a parallel reactivity study[J]. Waste Management, 2014, 34(10): 1815-1822. |

| 42 | Saranya D, Shanthakumar S. Opportunities for phycoremediation approach in tannery effluent: a treatment perspective[J]. Environmental Progress & Sustainable Energy, 2019, 38(3): e13078. |

| 43 | Yun Y S, Lee S B, Park J M, et al. Carbon dioxide fixation by algal cultivation using wastewater nutrients[J]. Journal of Chemical Technology & Biotechnology, 1997, 69(4): 451-455. |

| 44 | Lacerda L M C F, Queiroz M I, Furlan L T, et al. Improving refinery wastewater for microalgal biomass production and CO2 biofixation: predictive modeling and simulation[J]. Journal of Petroleum Science and Engineering, 2011, 78(3/4): 679-686. |

| 45 | Tarlan E, Dilek F B, Yetis U. Effectiveness of algae in the treatment of a wood-based pulp and paper industry wastewater[J]. Bioresource Technology, 2002, 84(1): 1-5. |

| 46 | Chang W T, Lee M, Den W. Simultaneous carbon capture, biomass production, and diary wastewater purification by spirulina maxima photobioreaction[J]. Industrial & Engineering Chemistry Research, 2013, 52(5): 2046-2055. |

| 47 | Chinnasamy S, Bhatnagar A, Hunt R W, et al. Microalgae cultivation in a wastewater dominated by carpet mill effluents for biofuel applications[J]. Bioresource Technology, 2010, 101(9): 3097-3105. |

| 48 | Lackner K S. A guide to CO2 sequestration[J]. Science, 2003, 300(5626): 1677-1678. |

| 49 | Baciocchi R, Costa G, Di Bartolomeo E, et al. The effects of accelerated carbonation on CO2 uptake and metal release from incineration APC residues[J]. Waste Management, 2009, 29(12): 2994-3003. |

| 50 | Wine R, Morrison R. Effective use of carbon dioxide for pH control in utility service and waste waters[C]//Proceedings of the American Power Conference. Illinois Institute of Technology, 1986: 1042-1045. |

| 51 | 应宝华. 利用二氧化碳降低碱性废水pH值工艺实践[J]. 现代冶金, 2011, 39(6): 28-31. |

| Ying B H. Lipid production of Chlorella vulgaris cultured in artificial wastewater medium[J]. Modern Metallurgy, 2011, 39(6): 28-31. | |

| 52 | Feng Y J, Li C, Zhang D W. Lipid production of Chlorella vulgaris cultured in artificial wastewater medium[J]. Bioresource Technology, 2011, 102(1): 101-105. |

| 53 | 应宝华. 二氧化碳处理法在钢铁工业废水处理回用中的应用[J]. 现代冶金, 2012, 40(2): 37-39. |

| Ying B H. Application of carbon dioxide treatment method in wastewater treatment and reuse in iron and steel industry[J]. Modern Metallurgy, 2012, 40(2): 37-39. | |

| 54 | Pan S Y, Chiang P C, Chen Y H, et al. Ex situ CO2 capture by carbonation of steelmaking slag coupled with metalworking wastewater in a rotating packed bed[J]. Environmental Science & Technology, 2013, 47(7): 3308-3315. |

| 55 | Costa G, Baciocchi R, Polettini A, et al. Current status and perspectives of accelerated carbonation processes on municipal waste combustion residues[J]. Environmental Monitoring and Assessment, 2007, 135(1/2/3): 55-75. |

| 56 | Huntzinger D N, Gierke J S, Kawatra S K, et al. Carbon dioxide sequestration in cement kiln dust through mineral carbonation[J]. Environmental Science & Technology, 2009, 43(6): 1986-1992. |

| 57 | Uibu M, Kuusik R. Mineral trapping of CO2via oil shale ash aqueous carbonation: controlling mechanism of process rate and development of continuous-flow reactor system[J]. Oil Shale, 2009, 26(1): 40-58. |

| 58 | Huijgen W J J, Witkamp G J, Comans R N J. Mineral CO2 sequestration by steel slag carbonation[J]. Environmental Science & Technology, 2005, 39(24): 9676-9682. |

| 59 | Kodama S, Nishimoto T, Yamamoto N, et al. Development of a new pH-swing CO2 mineralization process with a recyclable reaction solution[J]. Energy, 2008, 33(5): 776-784. |

| 60 | Chuajiw W, Nakano M, Takatori K, et al. Effects of amine, amine salt and amide on the behaviour of carbon dioxide absorption into calcium hydroxide suspension to precipitate calcium carbonate[J]. Journal of Environmental Sciences, 2013, 25(12): 2507-2515. |

| 61 | 贺翩翩, 刘晓静, 范勇, 等. 磷石膏固碳制备CaCO3的实验研究[J]. 非金属矿, 2015, 38(2): 28-30. |

| He P P, Liu X J, Fan Y, et al. Study on the preparation of CaCO3 by phosphogypsum solid carbon through orthogonal experiment[J]. Non-Metallic Mines, 2015, 38(2): 28-30. | |

| 62 | Wang B, Pan Z H, Du Z P, et al. Effect of impure components in flue gas desulfurization (FGD) gypsum on the generation of polymorph CaCO3 during carbonation reaction[J]. Journal of Hazardous Materials, 2019, 369: 236-243. |

| 63 | Gajda I, Greenman J, Melhuish C, et al. Microbial fuel cell-driven caustic potash production from wastewater for carbon sequestration[J]. Bioresource Technology, 2016, 215: 285-289. |

| 64 | Narasimhan A. Microalgal bioremediation of nutrients in wastewater and carbon dioxide in flue gas[J]. Fuel, 2010, 68(8):1079-1081. |

| 65 | Huang B, Marchand J, Thiriet-Rupert S, et al. Betaine lipid and neutral lipid production under nitrogen or phosphorus limitation in the marine microalga Tisochrysis lutea (Haptophyta)[J]. Algal Research, 2019, 40: 101506. |

| 66 | Chisti Y. Biodiesel from microalgae[J]. Biotechnology Advances, 2007, 25(3): 294-306. |

| 67 | Ma F R, Hanna M A. Biodiesel production: a review[J]. Bioresource Technology, 1999, 70(1): 1-15. |

| 68 | Shen Y F. Carbon dioxide bio-fixation and wastewater treatment via algae photochemical synthesis for biofuels production[J]. RSC Advances, 2014, 4(91): 49672-49722. |

| 69 | Acién Fernández F G, González-López C V, Fernández Sevilla J M, et al. Conversion of CO2 into biomass by microalgae: how realistic a contribution may it be to significant CO2 removal? [J]. Applied Microbiology and Biotechnology, 2012, 96(3): 577-586. |

| 70 | Huijgen W J, Comans R N. Carbonation of steel slag for CO2 sequestration: leaching of products and reaction mechanisms[J]. Environmental Science & Technology, 2006, 40(8): 2790-2796. |

| 71 | Hussain S I, Blowes D W, Ptacek C J, et al. Phosphorus removal from lake water using basic oxygen furnace slag: system performance and characterization of reaction products[J]. Environmental Engineering Science, 2014, 31(11): 631-642. |

| 72 | 王雷, 陈启, 高鹤华, 等. 高碱性废液中CO2曝气Cu的混合沉淀特性[J]. 沈阳航空航天大学学报, 2016, 33(1): 60-64. |

| Wang L, Chen Q, Gao H H, et al. Mixed precipitation characteristics of Cu in high alkaline waste by CO2 bubbling[J]. Journal of Shenyang Aerospace University, 2016, 33(1): 60-64. | |

| 73 | Praveen P, Xiao W, Lamba B, et al. Low-retention operation to enhance biomass productivity in an algal membrane photobioreactor[J]. Algal Research, 2019, 40: 101487. |

| 74 | Sheng M P, Xie C X, Sun B C, et al. Effective mass transfer area measurement using a CO2-NaOH system: impact of different sources of kinetics models and physical properties[J]. Industrial & Engineering Chemistry Research, 2019, 58(25): 11082-11092. |

| 75 | Huang Y, Huang Y, Liao Q, et al. Improving phosphorus removal efficiency and Chlorella vulgaris growth in high-phosphate MFC wastewater by frequent addition of small amounts of nitrate[J]. International Journal of Hydrogen Energy, 2017, 42(45): 27749-27758. |

| 76 | 李磊, 张红兵, 李文涛, 等. 光生物反应器培养微藻研究进展[J]. 生物技术进展, 2020, 10(2): 117-123. |

| Li L, Zhang H B, Li W T, et al. Progress on photobioreactors for microalgae cultivation[J]. Current Biotechnology, 2020, 10(2): 117-123. | |

| 77 | Iizuka A, Fujii M, Yamasaki A, et al. Development of a new CO2 sequestration process utilizing the carbonation of waste cement[J]. Industrial & Engineering Chemistry Research, 2004, 43(24): 7880-7887. |

| 78 | Park A H A, Fan L S. CO2 mineral sequestration: physically activated dissolution of serpentine and pH swing process[J]. Chemical Engineering Science, 2004, 59(22/23): 5241-5247. |

| 79 | Dabas N, Yadav K K, Ganguli A K, et al. New process for conversion of hazardous industrial effluent of ceramic industry into nanostructured sodium carbonate and their application in textile industry[J]. Journal of Environmental Management, 2019, 240: 352-358. |

| 80 | Costa J A V, de Morais M G. The role of biochemical engineering in the production of biofuels from microalgae[J]. Bioresource Technology, 2011, 102(1): 2-9. |

| 81 | Znad H, Naderi G, Ang H M, et al. CO2 biomitigation and biofuel production using microalgae: photobioreactors developments and future directions[M]//Advances in Chemical Engineering. Croatia: InTech, 2012: 229-244.. |

| 82 | Gordon J M, Polle J E W. Ultrahigh bioproductivity from algae[J]. Applied Microbiology and Biotechnology, 2007, 76(5): 969-975. |

| 83 | Demirbas A, Fatih Demirbas M. Importance of algae oil as a source of biodiesel[J]. Energy Conversion and Management, 2011, 52(1): 163-170. |

| 84 | Huber G W, Iborra S, Corma A. Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering[J]. Chemical Reviews, 2006, 106(9): 4044-4098. |

| 85 | Gebreslassie B H, Waymire R, You F Q. Sustainable design and synthesis of algae-based biorefinery for simultaneous hydrocarbon biofuel production and carbon sequestration[J]. AIChE Journal, 2013, 59(5): 1599-1621. |

| 86 | Polettini A, Pomi R, Stramazzo A. CO2 sequestration through aqueous accelerated carbonation of BOF slag: a factorial study of parameters effects[J]. Journal of Environmental Management, 2016, 167: 185-195. |

| 87 | 于成烈. 用废气CO2处理乙烯生产中的废碱液[J]. 石油化工, 1984, 13(6): 405-410. |

| Yu C L. Treatment of waste lye in ethylene production with waste gas CO2[J]. Petrochemical Technology, 1984, 13(6): 405-410. | |

| 88 | SundarRajan P, Gopinath K P, Greetham D, et al. A review on cleaner production of biofuel feedstock from integrated CO2 sequestration and wastewater treatment system[J]. Journal of Cleaner Production, 2019, 210: 445-458. |

| 89 | 马铭婧, 郗凤明, 王娇月, 等. 高炉渣CO2矿化利用技术的生命周期碳排放与成本评价[J]. 生态学杂志, 2020, 39(6): 2097-2105. |

| Ma M J, Xi F M, Wang J Y, et al. Life cycle carbon emissions and cost assessment of CO2 mineralization and utilization technology by means of blast furnace slag[J]. Chinese Journal of Ecology, 2020, 39(6): 2097-2105. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [3] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [4] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [7] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [8] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [9] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [10] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [11] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [12] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [13] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [14] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [15] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号