化工学报 ›› 2020, Vol. 71 ›› Issue (8): 3770-3779.DOI: 10.11949/0438-1157.20200126

张永胜1,2( ),张亮1,2(

),张亮1,2( ),李俊1,2,付乾1,2,朱恂1,2,廖强1,2,石雨1,2

),李俊1,2,付乾1,2,朱恂1,2,廖强1,2,石雨1,2

收稿日期:2020-02-10

修回日期:2020-03-28

出版日期:2020-08-05

发布日期:2020-08-05

通讯作者:

张亮

作者简介:张永胜(1994—),男,硕士研究生,基金资助:

Yongsheng ZHANG1,2( ),Liang ZHANG1,2(

),Liang ZHANG1,2( ),Jun LI1,2,Qian FU1,2,Xun ZHU1,2,Qiang LIAO1,2,Yu SHI1,2

),Jun LI1,2,Qian FU1,2,Xun ZHU1,2,Qiang LIAO1,2,Yu SHI1,2

Received:2020-02-10

Revised:2020-03-28

Online:2020-08-05

Published:2020-08-05

Contact:

Liang ZHANG

摘要:

以采用泡沫铜电极的热再生氨电池(thermally regenerative ammonia-based battery,TRAB)为研究对象,建立了多孔介质内物质传输与电化学反应耦合的稳态模型,计算获得了电池性能及多孔电极内物质传输特性,并研究了电解质浓度和电极孔隙率对电池性能的影响。研究结果表明,从主流区界面到多孔电极内部,阳极氨和阴极铜离子浓度逐渐降低,存在一定的浓度梯度,而且随着反应电流的增大,浓度梯度明显增大。在一定的范围内分别增大阳极氨浓度和阴极铜离子浓度,从主流区向多孔电极内物质传输增强,电池性能均能不断提升;随着硫酸铵浓度的增大,电解质电导率增大,电池性能逐渐提升,但增幅逐渐减小。此外,多孔电极孔隙率也会影响电池性能,本研究中TRAB在电极孔隙率为0.6时获得最高的最大功率(15.3 mW)。

中图分类号:

张永胜, 张亮, 李俊, 付乾, 朱恂, 廖强, 石雨. 采用泡沫铜电极的热再生氨电池性能数值模拟[J]. 化工学报, 2020, 71(8): 3770-3779.

Yongsheng ZHANG, Liang ZHANG, Jun LI, Qian FU, Xun ZHU, Qiang LIAO, Yu SHI. Numerical simulation of performance of thermally regenerative ammonia-based battery with copper foam electrode[J]. CIESC Journal, 2020, 71(8): 3770-3779.

| 参数 | 符号 | 数值/mm |

|---|---|---|

| 阳极腔室长度 | LAL | 30 |

| 阴极腔室长度 | LCL | 30 |

| 泡沫铜阳极厚度 | LAC | 4 |

| 泡沫铜阴极厚度 | LCC | 4 |

| 阴离子交换膜厚度 | LAEM | 1 |

| 电极高度 | H | 30 |

表1 几何区域尺寸参数

Table 1 Dimensional parameters of geometrical domain

| 参数 | 符号 | 数值/mm |

|---|---|---|

| 阳极腔室长度 | LAL | 30 |

| 阴极腔室长度 | LCL | 30 |

| 泡沫铜阳极厚度 | LAC | 4 |

| 泡沫铜阴极厚度 | LCC | 4 |

| 阴离子交换膜厚度 | LAEM | 1 |

| 电极高度 | H | 30 |

| 参数 | 符号 | 数值 | 来源 |

|---|---|---|---|

| Cu2+扩散系数/(m2/s) | 1.5×10-9 | 文献[ | |

| 0.6 ×10-9 | 文献[ | ||

| NH3扩散系数/ (m2/s) | 1.7×10-9 | 文献[ | |

| 0.95 ×10-9 | 文献[ | ||

| 电极孔隙率 | 0.9 | — | |

| 电极活性比表面积/ (m2/m3) | 4985 | 测量 | |

| Cu2+参考浓度/ (mol/L) | 1 | — | |

| 操作温度/K | T | 298.15 | 测量 |

| 阳极电解质电导率/ (S/m) | 6.3 | 测量 | |

| 阴极电解质电导率/ (S/m) | 7.8 | 测量 | |

| 阳极反应速度常量/ (m/s) | 7 ×10-7 | 文献[ | |

| 阴极反应速度常量/(m/s) | 5 ×10-6 | 文献[ | |

| Cu2+初始浓度/ (mol/L) | 0.1 | — | |

| 0.5 | — | ||

| 0.1 | — | ||

| NH3?H2O初始浓度/ (mol/L) | 0.6 | — | |

| 反应(9)阴极传递系数 | 0.36 | — | |

| 反应(10)阴极传递系数 | 0.64 | — | |

| 0.5 | — | ||

| 0.5 | — |

表2 模型中所使用的参数

Table 2 Parameters used in the model

| 参数 | 符号 | 数值 | 来源 |

|---|---|---|---|

| Cu2+扩散系数/(m2/s) | 1.5×10-9 | 文献[ | |

| 0.6 ×10-9 | 文献[ | ||

| NH3扩散系数/ (m2/s) | 1.7×10-9 | 文献[ | |

| 0.95 ×10-9 | 文献[ | ||

| 电极孔隙率 | 0.9 | — | |

| 电极活性比表面积/ (m2/m3) | 4985 | 测量 | |

| Cu2+参考浓度/ (mol/L) | 1 | — | |

| 操作温度/K | T | 298.15 | 测量 |

| 阳极电解质电导率/ (S/m) | 6.3 | 测量 | |

| 阴极电解质电导率/ (S/m) | 7.8 | 测量 | |

| 阳极反应速度常量/ (m/s) | 7 ×10-7 | 文献[ | |

| 阴极反应速度常量/(m/s) | 5 ×10-6 | 文献[ | |

| Cu2+初始浓度/ (mol/L) | 0.1 | — | |

| 0.5 | — | ||

| 0.1 | — | ||

| NH3?H2O初始浓度/ (mol/L) | 0.6 | — | |

| 反应(9)阴极传递系数 | 0.36 | — | |

| 反应(10)阴极传递系数 | 0.64 | — | |

| 0.5 | — | ||

| 0.5 | — |

| 源/汇 | 阳极 | 阴极 |

|---|---|---|

| S1( | 0 | |

| S2( | 0 | |

| S3( | 0 |

表3 物质守恒方程源项

Table 3 Source items of the mass conservation equation

| 源/汇 | 阳极 | 阴极 |

|---|---|---|

| S1( | 0 | |

| S2( | 0 | |

| S3( | 0 |

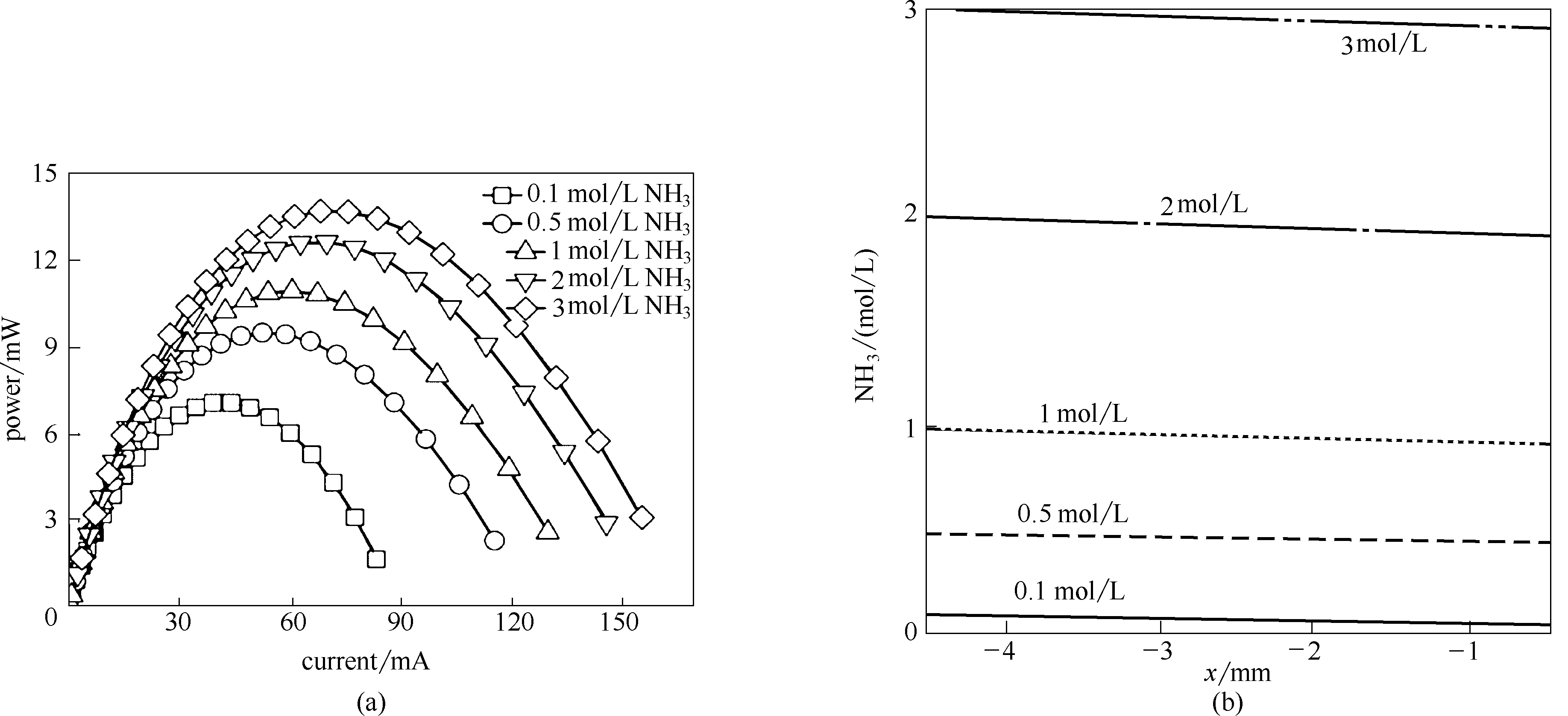

图4 不同氨浓度对电池性能的影响(a)及阳极氨浓度分布(b)

Fig.4 Effects of different ammonia concentration on battery performance (a) and distribution of ammonia concentration (b)

| 硫酸铵浓度/(mol/L) | 阴极电解液电导率 | 阳极电解液电导率 |

|---|---|---|

| 0.5 | 7.8 | 6.3 |

| 1 | 13.3 | 11.3 |

| 1.5 | 22 | 19.9 |

| 2 | 25.6 | 23.5 |

| 2.5 | 28.9 | 26.7 |

表4 不同硫酸铵浓度的电解液电导率

Table 4 Conductivity of the electrolyte with different concentration of (NH4)2SO4

| 硫酸铵浓度/(mol/L) | 阴极电解液电导率 | 阳极电解液电导率 |

|---|---|---|

| 0.5 | 7.8 | 6.3 |

| 1 | 13.3 | 11.3 |

| 1.5 | 22 | 19.9 |

| 2 | 25.6 | 23.5 |

| 2.5 | 28.9 | 26.7 |

| 1 | Lu H Y, Price L, Zhang Q. Capturing the invisible resource: analysis of waste heat potential in Chinese industry[J]. Applied Energy, 2016, 161: 497-511. |

| 2 | Jouhara H, Khordehgah N, Almahmoud S, et al. Waste heat recovery technologies and applications[J]. Thermal Science and Engineering Progress, 2018, 6: 268-289. |

| 3 | Woolley E, Luo Y, Simeone A. Industrial waste heat recovery: a systematic approach[J]. Sustainable Energy Technologies and Assessments, 2018, 29: 50-59. |

| 4 | 陈昕, 王如竹. 一种低温余热高效利用的氨水动力循环[J]. 化工学报, 2016, 67(9): 3536-3544. |

| Chen X, Wang R Z. An efficient ammonia-water power cycle in low temperature waste heat application[J]. CIESC Journal, 2016, 67(9): 3536-3544. | |

| 5 | 刘超, 徐进良. 一种新型天然气锅炉烟气余热回收系统[J]. 化工学报, 2013, 64(11): 4223-4230. |

| Liu C, Xu J L. A novel heat recovery system for flue gas from natural gas boiler[J]. CIESC Journal, 2013, 64(11): 4223-4230. | |

| 6 | 路会同, 江龙, 王丽伟, 等. 低温余热驱动的无泵有机朗肯循环瞬时稳态发电性能[J]. 化工学报, 2017, 68(12): 4709-4716. |

| Lu H T, Jiang L, Wang L W, et al. Instantaneous steady state of pumpless organic Rankine cycle driven by low temperature heat source[J]. CIESC Journal, 2017, 68(12): 4709-4716. | |

| 7 | 谢飞博, 朱彤, 高乃平. 冷源温度对小型ORC低温余热发电系统的影响[J]. 化工学报, 2016, 67(10): 4111-4117. |

| Xie F B, Zhu T, Gao N P. Effect of cold source temperature on power generation of small organic Rankine cycle system with low-grade waste heat[J]. CIESC Journal, 2016, 67(10): 4111-4117. | |

| 8 | Bell L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems[J]. Science, 2008, 321(5895): 1457-1461. |

| 9 | Abraham T J, Macfarlane D R, Baughman R H, et al. Towards ionic liquid-based thermoelectrochemical cells for the harvesting of thermal energy[J]. Electrochimica Acta, 2013, 113: 87-93. |

| 10 | Rahimi M, Straub A P, Zhang F, et al. Emerging electrochemical and membrane-based systems to convert low-grade heat to electricity[J]. Energy & Environmental Science, 2018, 11(2): 276-285. |

| 11 | Straub A P, Deshmukh A, Elimelech M. Pressure-retarded osmosis for power generation from salinity gradients: is it viable?[J]. Energy & Environmental Science, 2016, 9(1): 31-48. |

| 12 | Kim T, Rahimi M, Logan B E, et al. Harvesting energy from salinity differences using battery electrodes in a concentration flow cell[J]. Environmental Science & Technology, 2016, 50(17): 9791-9797. |

| 13 | Al-Masri D, Dupont M, Yunis R, et al. The electrochemistry and performance of cobalt-based redox couples for thermoelectrochemical cells[J]. Electrochimica Acta, 2018, 269: 714-723. |

| 14 | Anari E H B, Romano M, Teh W X, et al. Substituted ferrocenes and iodine as synergistic thermoelectrochemical heat harvesting redox couples in ionic liquids[J]. Chemical Communications, 2016, 52(4): 745-748. |

| 15 | Marino M, Misuri L, Carati A, et al. Boosting the voltage of a salinity-gradient-power electrochemical cell by means of complex-forming solutions[J]. Applied Physics Letters, 2014, 105: 0339013. |

| 16 | Zhang F, Liu J, Yang W L, et al. A thermally regenerative ammonia-based battery for efficient harvesting of low-grade thermal energy as electrical power[J]. Energy & Environmental Science, 2015, 8(1): 343-349. |

| 17 | Zhu X P, Rahimi M, Gorski C A, et al. A thermally-regenerative ammonia-based flow battery for electrical energy recovery from waste heat[J]. ChemSusChem, 2016, 9(8): 873-879. |

| 18 | Zhang F, Labarge N, Yang W L, et al. Enhancing low-grade thermal energy recovery in a thermally regenerative ammonia battery using elevated temperatures[J]. ChemSusChem, 2015, 8(6): 1043-1048. |

| 19 | Rahimi M, Zhu L, Kowalski K L, et al. Improved electrical power production of thermally regenerative batteries using a poly(phenylene oxide) based anion exchange membrane[J]. Journal of Power Sources, 2017, 342: 956-963. |

| 20 | Rahimi M, D􀆳Angelo A, Gorski C A,et al. Electrical power production from low-grade waste heat using a thermally regenerative ethylenediamine battery[J]. Journal of Power Sources, 2017, 351: 45-50. |

| 21 | Rahimi M, Kim T, Gorski C A, et al. A thermally regenerative ammonia battery with carbon-silver electrodes for converting low-grade waste heat to electricity[J]. Journal of Power Sources, 2018, 373: 95-102. |

| 22 | Wang W G, Shu G Q, Tian H, et al. A bimetallic thermally-regenerative ammonia-based flow battery for low-grade waste heat recovery[J]. Journal of Power Sources, 2019, 424: 184-192. |

| 23 | 王福添, 张绍志, 陈光明. 热再生氨化学电池的实验研究及热力学分析[J]. 热能动力工程, 2018, 33(9): 132-137. |

| Wang F T, Zhang S Z, Chen G M. Experimental study and thermodynamic analysis on thermally regenerative ammonia battery[J]. Journal of Engineering for Thermal Energy and Power, 2018, 33(9): 132-137. | |

| 24 | Rahimi M, Schoener Z, Zhu X P, et al. Removal of copper from water using a thermally regenerative electrodeposition battery[J]. Journal of Hazardous Materials, 2017, 322(B): 551-556. |

| 25 | 唐志强, 张亮, 朱恂, 等. 不同Cu2+浓度下热再生氨电池产电及Cu2+去除特性[J]. 化工学报, 2019, 70(12): 4804-4810. |

| Tang Z Q, Zhang L, Zhu X, et al. Effect of Cu2+ concentration in cathode on power generation and copper removal of thermally regenerative ammonia-based battery[J]. CIESC Journal, 2019, 70(12): 4804-4810. | |

| 26 | 张绍志, 王福添, 陈光明, 等. 一种输出电能的第二类吸收式热泵: 2016105464590[P]. 2016-07-13. |

| Zhang S Z, Wang F T, Chen G M, et al. A second kind of absorption heat pump for energy output: 2016105464590[P]. 2016-07-13. | |

| 27 | 张绍志, 王福添, 陈光明, 等. 一种低品位热驱动的冷电联供系统及其应用方法: 2016109965536[P]. 2016-11-13. |

| Zhang S Z, Wang F T, Chen G M, et al. A low-grade thermal driven cold electricity cogeneration system and its application method: 2016109965536[P]. 2016-11-13. | |

| 28 | Vicari F, D􀆳Angelo A, Kouko Y,et al. On the regeneration of thermally regenerative ammonia batteries[J]. Journal of Applied Electrochemistry,2018, 48(12SI): 1381-1388. |

| 29 | 王福添. 热再生氨化学电池的电极反应及基本循环研究[D]. 杭州: 浙江大学, 2018. |

| Wang F T. Study on the electrode reaction and basic cycle of the thermally regenerative ammonia battery[D]. Hangzhou: Zhejiang University, 2018. | |

| 30 | Zhang L, Li Y X, Zhu X, et al. Copper foam electrodes for increased power generation in thermally regenerative ammonia-based batteries for low-grade waste heat recovery[J]. Industrial & Engineering Chemistry Research, 2019, 58(17): 7408-7415. |

| 31 | 李彦翔, 张亮, 朱恂, 等. 传质对热可再生氨电池性能的影响[J]. 工程热物理学报, 2019, (3): 668-671. |

| Li Y X, Zhang L, Zhu X, et al. Effect of mass transfer on the performance of thermally regenerative ammonia-based battery[J]. Journal of Engineering Thermophysics, 2019, (3): 668-671. | |

| 32 | Zhang Y S, Zhang L, Li J, et al. Performance of a thermally regenerative ammonia-based flow battery with 3D porous electrodes: effect of reactor and electrode design[J]. Electrochimica Acta, 2020, 331: 135442. |

| 33 | Wang W, Shu G, Tian H, et al. A numerical model for a thermally-regenerative ammonia-based flow battery using for low grade waste heat recovery[J]. Journal of Power Sources, 2018, 388: 32-44. |

| 34 | 高明峰. 钒微流控燃料电池的数值模拟研究[D]. 长春: 吉林大学, 2012. |

| Gao M F. Numerical simulation study on vanadium microfluidic fuel cell[D]. Changchun: Jilin University, 2012. | |

| 35 | Wang R, Li Y, He Y. Achieving gradient-pore-oriented graphite felt for vanadium redox flow batteries: meeting improved electrochemical activity and enhanced mass transport from nano-to micro-scale[J]. Journal of Materials Chemistry A, 2019, 7(18): 10962-10970. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [8] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [9] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [10] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [11] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [12] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [15] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号