化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4146-4154.DOI: 10.11949/0438-1157.20201906

梁坤峰1( ),米国强1,徐红玉2,高春艳1,董彬1,李亚超1,王莫然1

),米国强1,徐红玉2,高春艳1,董彬1,李亚超1,王莫然1

收稿日期:2020-12-24

修回日期:2021-05-18

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

梁坤峰

作者简介:梁坤峰(1975—),男,博士,教授,基金资助:

Kunfeng LIANG1( ),Guoqiang MI1,Hongyu XU2,Chunyan GAO1,Bin DONG1,Yachao LI1,Moran WANG1

),Guoqiang MI1,Hongyu XU2,Chunyan GAO1,Bin DONG1,Yachao LI1,Moran WANG1

Received:2020-12-24

Revised:2021-05-18

Online:2021-08-05

Published:2021-08-05

Contact:

Kunfeng LIANG

摘要:

基于工质相变热虹吸效应,提出了动力电池双向热管理系统,通过改变工质充注量,60~220 g时,试验测试了该系统的双向热管理性能,并据此进行系统优化。结果表明:该热管理系统的正常运行有一个最低充注量。系统优化前,加热工况,系统换热功率受充注量的影响小;散热工况,系统的换热功率随充注量的增加而增大,随电池箱初始温度升高而增大,且强制散热效果要优于自然散热;相同充注量,换热板表面的最大温差随电池箱初始温度升高而增大,在3C放电倍率,无法控制电池表面温度低于45℃。系统优化后,圆管换热板系统的换热效果要优于矩形管换热板系统,且在3C放电倍率能将电池表面温度降低至43.4℃,换热板的温度一致性更好。

中图分类号:

梁坤峰, 米国强, 徐红玉, 高春艳, 董彬, 李亚超, 王莫然. 动力电池双向热管理系统性能分析与优化[J]. 化工学报, 2021, 72(8): 4146-4154.

Kunfeng LIANG, Guoqiang MI, Hongyu XU, Chunyan GAO, Bin DONG, Yachao LI, Moran WANG. Performance analysis and optimization of two-way thermal management system for power battery[J]. CIESC Journal, 2021, 72(8): 4146-4154.

密度/ (kg/m3) | 比热容/ (J/(kg·℃)) | 额定 容量/ (A·h) | 标称 电压/V | 内阻/ Ω | 尺寸/ (mm |

|---|---|---|---|---|---|

| 2492 | 1183.24 | 17 | 3.7 |

表1 电池参数

Table 1 Battery parameters

密度/ (kg/m3) | 比热容/ (J/(kg·℃)) | 额定 容量/ (A·h) | 标称 电压/V | 内阻/ Ω | 尺寸/ (mm |

|---|---|---|---|---|---|

| 2492 | 1183.24 | 17 | 3.7 |

| 放电倍率 | 放电时间/s | 生热速率/W | 产热量/J | 温升/℃ |

|---|---|---|---|---|

| 1C | 3868 | 1.57 | 6071 | 9.5 |

| 2C | 1910 | 6.15 | 11743 | 18.4 |

| 3C | 1260 | 13.26 | 16709 | 26.2 |

表2 电池热特性参数

Table 2 Thermal characteristic parameters of battery

| 放电倍率 | 放电时间/s | 生热速率/W | 产热量/J | 温升/℃ |

|---|---|---|---|---|

| 1C | 3868 | 1.57 | 6071 | 9.5 |

| 2C | 1910 | 6.15 | 11743 | 18.4 |

| 3C | 1260 | 13.26 | 16709 | 26.2 |

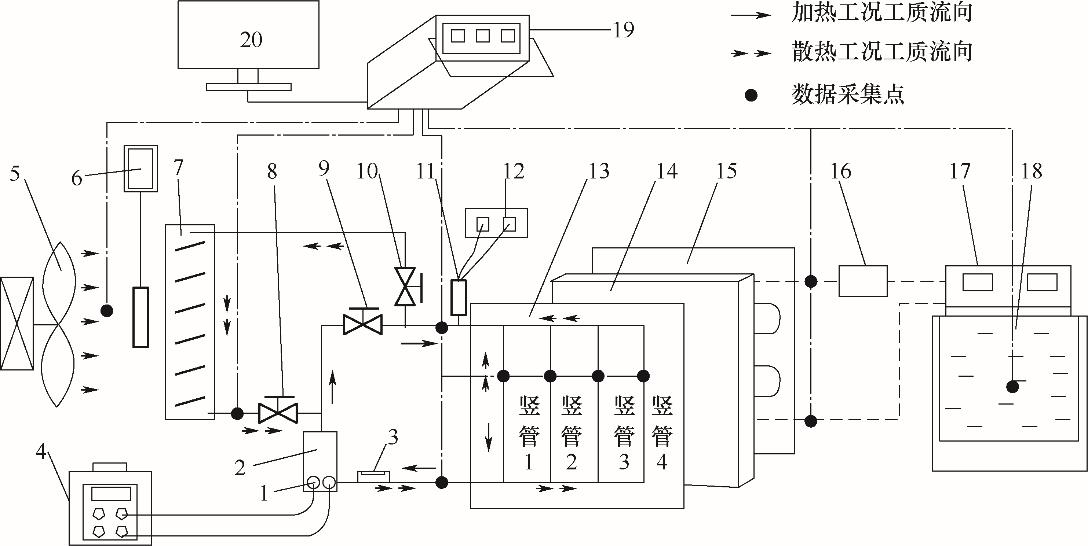

图1 系统试验结构图1—加热棒;2—气泡泵;3—视液镜;4—调压器;5—风机;6—热线风速仪;7—翅片管式冷凝器;8,9,10—单向阀;11—压力传感器;12—直流稳压电源;13—前换热板;14—导热硅胶片;15—后换热板;16—循环水泵;17—温控部件;18—溶液槽(模拟电池箱);19—数据采集系统;20—上位机

Fig.1 Schematic diagram of experimental system

电池箱 初始 温度/℃ | 最大温差/℃ | ||||

|---|---|---|---|---|---|

| 60 g | 100 g | 140 g | 180 g | 220 g | |

| 40 | 1.7 | 1.3 | 1.2 | 1.9 | 2.3 |

| 50 | 1.8 | 1.9 | 1.9 | 3.3 | 3.7 |

| 60 | 2.4 | 2.2 | 2.9 | 4.2 | 5.1 |

| 70 | 3.3 | 3.5 | 4.9 | 4.6 | 5.6 |

表3 强制散热四根竖管的最大温差

Table 3 The maximum temperature difference of the four vertical pipes with forced cooling

电池箱 初始 温度/℃ | 最大温差/℃ | ||||

|---|---|---|---|---|---|

| 60 g | 100 g | 140 g | 180 g | 220 g | |

| 40 | 1.7 | 1.3 | 1.2 | 1.9 | 2.3 |

| 50 | 1.8 | 1.9 | 1.9 | 3.3 | 3.7 |

| 60 | 2.4 | 2.2 | 2.9 | 4.2 | 5.1 |

| 70 | 3.3 | 3.5 | 4.9 | 4.6 | 5.6 |

| 充注量/g | 圆管换热板系统电池箱初温/℃ | 矩形管换热板系统电池箱初温/℃ | ||||||

|---|---|---|---|---|---|---|---|---|

| 40 | 50 | 60 | 70 | 40 | 50 | 60 | 70 | |

| 60 | 45.9% | 40.8% | 35.3% | 28.4% | -26.5% | -53.9% | -56.0% | -57.1% |

| 100 | 50.9% | 24.8% | 24.7% | 17.9% | -28.1% | -40.2% | -33.6% | -36.3% |

| 140 | 32.5% | 10.0% | -7.7% | -5.4% | -7.0% | -8.5% | -16.1% | -11.1% |

| 180 | 12.7% | -6.9% | -18.4% | -15.6% | 54.8% | 8.5% | -4.9% | -5.4% |

| 220 | 50.3% | 9.5% | 1.9% | -0.9% | 66% | 9.0% | 1.9% | -5.7% |

表4 优化后的系统换热功率变化率

Table 4 Optimized system heat exchange power change rate

| 充注量/g | 圆管换热板系统电池箱初温/℃ | 矩形管换热板系统电池箱初温/℃ | ||||||

|---|---|---|---|---|---|---|---|---|

| 40 | 50 | 60 | 70 | 40 | 50 | 60 | 70 | |

| 60 | 45.9% | 40.8% | 35.3% | 28.4% | -26.5% | -53.9% | -56.0% | -57.1% |

| 100 | 50.9% | 24.8% | 24.7% | 17.9% | -28.1% | -40.2% | -33.6% | -36.3% |

| 140 | 32.5% | 10.0% | -7.7% | -5.4% | -7.0% | -8.5% | -16.1% | -11.1% |

| 180 | 12.7% | -6.9% | -18.4% | -15.6% | 54.8% | 8.5% | -4.9% | -5.4% |

| 220 | 50.3% | 9.5% | 1.9% | -0.9% | 66% | 9.0% | 1.9% | -5.7% |

| 初始温度/℃ | 最大温差/℃ | ||||

|---|---|---|---|---|---|

| 60 g | 100 g | 140 g | 180 g | 220 g | |

| 40 | 0.8 | 0.8 | 1.4 | 0.9 | 1.3 |

| 50 | 1.0 | 1.3 | 0.9 | 1.9 | 1.7 |

| 60 | 1.4 | 2.2 | 2.6 | 1.3 | 2.1 |

| 70 | 1.9 | 3.1 | 2.9 | 1.5 | 2.4 |

表5 优化后强制散热四根竖管的最大温差

Table 5 The maximum temperature difference of the four vertical pipes with forced cooling after optimization

| 初始温度/℃ | 最大温差/℃ | ||||

|---|---|---|---|---|---|

| 60 g | 100 g | 140 g | 180 g | 220 g | |

| 40 | 0.8 | 0.8 | 1.4 | 0.9 | 1.3 |

| 50 | 1.0 | 1.3 | 0.9 | 1.9 | 1.7 |

| 60 | 1.4 | 2.2 | 2.6 | 1.3 | 2.1 |

| 70 | 1.9 | 3.1 | 2.9 | 1.5 | 2.4 |

| 放电倍率 | 电池温度/℃ | ||

|---|---|---|---|

| 无散热 | 原系统 | 圆管换热板系统 | |

| 1C | 34.5 | 32.4 | 31.7 |

| 2C | 43.4 | 39.5 | 37.1 |

| 3C | 51.2 | 46.5 | 43.4 |

表6 放电结束电池温度

Table 6 Battery temperature at the end of discharge

| 放电倍率 | 电池温度/℃ | ||

|---|---|---|---|

| 无散热 | 原系统 | 圆管换热板系统 | |

| 1C | 34.5 | 32.4 | 31.7 |

| 2C | 43.4 | 39.5 | 37.1 |

| 3C | 51.2 | 46.5 | 43.4 |

| 1 | Lin J Y, Liu X H, Li S, et al. A review on recent progress, challenges and perspective of battery thermal management system[J]. International Journal of Heat and Mass Transfer, 2021, 167: 120834. |

| 2 | Wang N, Pan H Z, Zheng W H. Assessment of the incentives on electric vehicle promotion in China[J]. Transportation Research Part A: Policy and Practice, 2017, 101: 177-189. |

| 3 | Choudhari V G, Dhoble D A S, Sathe T M. A review on effect of heat generation and various thermal management systems for lithium ion battery used for electric vehicle[J]. Journal of Energy Storage, 2020, 32: 101729. |

| 4 | Ataur R, Hawlader M N A, Khalid H. Two-phase evaporative battery thermal management technology for EVs/HEVs[J]. International Journal of Automotive Technology, 2017, 18(5): 875-882. |

| 5 | Lu M Y, Zhang X L, Ji J, et al. Research progress on power battery cooling technology for electric vehicles[J]. Journal of Energy Storage, 2020, 27: 101155. |

| 6 | Shen M, Gao Q. System simulation on refrigerant-based battery thermal management technology for electric vehicles[J]. Energy Conversion and Management, 2020, 203: 112176. |

| 7 | Saw L H, Ye Y H, Tay A A O, et al. Computational fluid dynamic and thermal analysis of lithium-ion battery pack with air cooling[J]. Applied Energy, 2016, 177: 783-792. |

| 8 | Na X Y, Kang H F, Wang T, et al. Reverse layered air flow for Li-ion battery thermal management[J]. Applied Thermal Engineering, 2018, 143: 257-262. |

| 9 | Akinlabi A A H, Solyali D. Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: a review[J]. Renewable and Sustainable Energy Reviews, 2020, 125: 109815. |

| 10 | Panchal S, Dincer I, Agelin-Chaab M, et al. Experimental and theoretical investigations of heat generation rates for a water cooled LiFePO4 battery[J]. International Journal of Heat and Mass Transfer, 2016, 101: 1093-1102. |

| 11 | 冯能莲, 马瑞锦, 陈龙科, 等. 新型蜂巢式液冷动力电池模块传热特性研究[J]. 化工学报, 2019, 70(5): 1713-1722. |

| Feng N L, Ma R J, Chen L K, et al. Heat transfer characteristics of honeycomb liquid-cooled power battery module[J]. CIESC Journal, 2019, 70(5): 1713-1722. | |

| 12 | Deng Y W, Feng C L, E J, et al. Effects of different coolants and cooling strategies on the cooling performance of the power lithium ion battery system: a review[J]. Applied Thermal Engineering, 2018, 142: 10-29. |

| 13 | Hong S H, Jang D S, Park S, et al. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles[J]. Applied Thermal Engineering, 2020, 173: 115213. |

| 14 | Smith J, Singh R, Hinterberger M, et al. Battery thermal management system for electric vehicle using heat pipes[J]. International Journal of Thermal Sciences, 2018, 134: 517-529. |

| 15 | Liu F F, Lan F C, Chen J Q, et al. Experimental investigation on cooling/heating characteristics of ultra-thin micro heat pipe for electric vehicle battery thermal management[J]. Chinese Journal of Mechanical Engineering, 2018, 31(1): 1-10. |

| 16 | Rao Z H, Wang Q C, Huang C L. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system[J]. Applied Energy, 2016, 164: 659-669. |

| 17 | Zou D Q, Liu X S, He R J, et al. Preparation of a novel composite phase change material (PCM) and its locally enhanced heat transfer for power battery module[J]. Energy Conversion and Management, 2019, 180: 1196-1202. |

| 18 | Qin Y D, Du J Y, Lu L G, et al. A rapid lithium-ion battery heating method based on bidirectional pulsed current: heating effect and impact on battery life[J]. Applied Energy, 2020, 280: 115957. |

| 19 | 朱建功, 孙泽昌, 魏学哲, 等. 车用锂离子电池低温特性与加热方法研究进展[J]. 汽车工程, 2019, 41(5): 571-581, 589. |

| Zhu J G, Sun Z C, Wei X Z, et al. Research progress on low-temperature characteristics and heating techniques of vehicle lithium-ion battery[J]. Automotive Engineering, 2019, 41(5): 571-581, 589. | |

| 20 | 梁坤峰, 米国强, 徐红玉, 等. 动力电池冷热双向循环热管理系统性能分析[J]. 农业工程学报, 2020, 36(14): 114-120. |

| Liang K F, Mi G Q, Xu H Y, et al. Performance analysis of power battery cooling or heating two-way cycling thermal management system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(14): 114-120. | |

| 21 | 张海南, 邵双全, 田长青. 多蒸发器热虹吸回路热管启动与不稳定性研究[J]. 工程热物理学报, 2020, 41(4): 792-796. |

| Zhang H N, Shao S Q, Tian C Q. Startup and instability of a loop thermosyphon with multiple evaporators[J]. Journal of Engineering Thermophysics, 2020, 41(4): 792-796. | |

| 22 | Chi R G, Chung W S, Rhi S H. Thermal characteristics of an oscillating heat pipe cooling system for electric vehicle Li-ion batteries[J]. Energies, 2018, 11(3): 655. |

| 23 | Xia G D, Cao L, Bi G L. A review on battery thermal management in electric vehicle application[J]. Journal of Power Sources, 2017, 367: 90-105. |

| 24 | Kim J, Oh J, Lee H. Review on battery thermal management system for electric vehicles[J]. Applied Thermal Engineering, 2019, 149: 192-212. |

| 25 | Jilte R, Afzal A, Panchal S. A novel battery thermal management system using nano-enhanced phase change materials[J]. Energy, 2021, 219: 119564. |

| 26 | An Z, Shah K, Jia L, et al. A parametric study for optimization of minichannel based battery thermal management system[J]. Applied Thermal Engineering, 2019, 154: 593-601. |

| 27 | Lin F L, Liu D P, Jiang D Q, et al. An experimental study on the performance of guided bubble pump with multiple tubes[J]. Applied Thermal Engineering, 2016, 106: 1052-1061. |

| 28 | 郜效保. 微型纯电动汽车电池包结构设计与碰撞安全性研究[D]. 长沙: 湖南大学, 2016. |

| Gao X B. A study on structure design of battery pack and collision safety based on micro electric vehicle[D]. Changsha: Hunan University, 2016. | |

| 29 | Liu H Q, Wei Z B, He W D, et al. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: a review[J]. Energy Conversion and Management, 2017, 150: 304-330. |

| 30 | 朱发明, 刘道平, 杨亮, 等. 均流式多管导流型气泡泵提升性能实验研究[J]. 制冷学报, 2018, 39(6): 84-90. |

| Zhu F M, Liu D P, Yang L, et al. Experimental research on improving performance of guided bubble pump with multiple tubes with current equalizer[J]. Journal of Refrigeration, 2018, 39(6): 84-90. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [3] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [4] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [7] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [8] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [9] | 诸程瑛, 王振雷. 基于改进深度强化学习的乙烯裂解炉操作优化[J]. 化工学报, 2023, 74(8): 3429-3437. |

| [10] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [11] | 汤晓玲, 王嘉瑞, 朱玄烨, 郑仁朝. 基于Pickering乳液的卤醇脱卤酶催化合成手性环氧氯丙烷[J]. 化工学报, 2023, 74(7): 2926-2934. |

| [12] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [13] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [14] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [15] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号