化工学报 ›› 2021, Vol. 72 ›› Issue (9): 4511-4522.DOI: 10.11949/0438-1157.20210512

刘辰玥1( ),郑通1,刘渊博1,温荣福1,陈凯2,马学虎1(

),郑通1,刘渊博1,温荣福1,陈凯2,马学虎1( )

)

收稿日期:2021-04-14

修回日期:2021-05-27

出版日期:2021-09-05

发布日期:2021-09-05

通讯作者:

马学虎

作者简介:刘辰玥(1995—),女,硕士研究生,

Chenyue LIU1( ),Tong ZHENG1,Yuanbo LIU1,Rongfu WEN1,Kai CHEN2,Xuehu MA1(

),Tong ZHENG1,Yuanbo LIU1,Rongfu WEN1,Kai CHEN2,Xuehu MA1( )

)

Received:2021-04-14

Revised:2021-05-27

Online:2021-09-05

Published:2021-09-05

Contact:

Xuehu MA

摘要:

开发高效低阻换热器是提升系统能量转化效率的重要途径,对于船舶航运工业和海上石油平台等海洋工程以及石油钻井平台等领域具有重要的意义。受鲨鱼鳃裂结构启发,设计了一种适用于受限空间内的异形仿生换热器,大幅释放空间,并提高了换热器的集成性。通过在换热器壳程添加四种不同形式的折流板,并在进口端引入“间隙流”,模拟分析了换热器壳侧流场、压力场和温度场的分布规律,并对比了不同Reynolds数下换热器的性能差异。结果表明,阶梯式隔板换热器可达到低阻特性,流速为0.5 m/s时,壳程压降相比于弓形折流板换热器和交错类折流板换热器分别下降了约82%和65%;当Reynolds数在15000~35000之间(流速约为0.63~1.46 m/s)时,进口间隙交错折流板换热器的高效低阻特性优势明显,比弓形折流板换热器提升了约12%;当Reynolds数大于35000即流速高于1.46 m/s时,阶梯式隔板换热器的综合性能比弓形折流板换热器高出约5%,可适用于对壳程压降要求更高的应用环境。给出了不同工况下的换热器综合性能评价图,为实际应用和设计分析提供指导。

中图分类号:

刘辰玥, 郑通, 刘渊博, 温荣福, 陈凯, 马学虎. 异形仿生换热器壳侧对流换热的高效低阻特性研究[J]. 化工学报, 2021, 72(9): 4511-4522.

Chenyue LIU, Tong ZHENG, Yuanbo LIU, Rongfu WEN, Kai CHEN, Xuehu MA. Shell side high efficiency and low resistance performance of heat exchanger with bionic structures[J]. CIESC Journal, 2021, 72(9): 4511-4522.

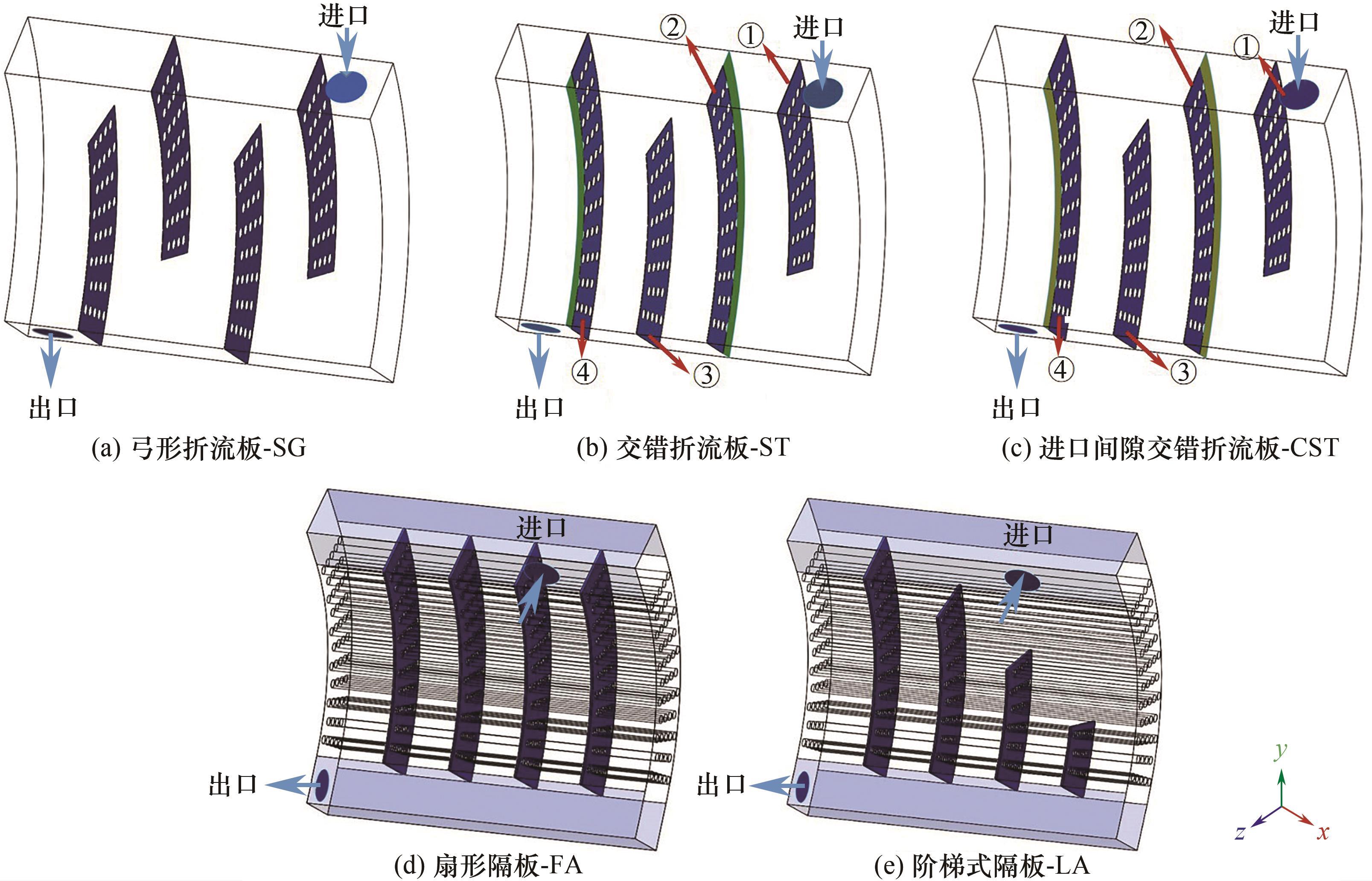

图2 异形仿生换热器结构及折流板布置示意图[图(d)、(e)中蓝色区域代表集水箱]

Fig.2 Structure diagram and baffle arrangement of special-shaped heat exchanger with bionic structures [The blue area in Fig. (d) and (e) represents the water collecting tank]

| 换热器设计参数 | 数值 |

|---|---|

| 弧度/(°) | 60 |

| 内半径/mm | 503.5 |

| 宽度/mm | 145 |

| 进出口直径/mm | 80 |

| 换热管尺寸/mm | ?20×2 |

| 换热管长度/mm | 750 |

| 换热管中心距/mm | 27 |

| 换热管数量 | 50 |

表1 异形仿生换热器外壳与换热管设计参数

Table 1 Tube and shell design parameters of special-shaped heat exchanger with bionic structures

| 换热器设计参数 | 数值 |

|---|---|

| 弧度/(°) | 60 |

| 内半径/mm | 503.5 |

| 宽度/mm | 145 |

| 进出口直径/mm | 80 |

| 换热管尺寸/mm | ?20×2 |

| 换热管长度/mm | 750 |

| 换热管中心距/mm | 27 |

| 换热管数量 | 50 |

| 换热器内部设计元件 | 设计参数 | 数值 |

|---|---|---|

| 折流板 | 折流板厚度/mm | 5 |

| 折流板数量 | 4 | |

| 折流板①和③缺口弧度占整体弧度的比例 | 29% | |

| 折流板②和④缺口宽度占整体宽度的比例 | 28%、26% | |

| 进口折流板处间隙 | 进口处管板间隙/mm | 1.5 |

表2 异形仿生弓形折流板、交错折流板和进口间隙交错折流板换热器内部设计参数

Table 2 Internal design parameters of SSBHX-SG, SSBHX-ST and SSBHX-CST

| 换热器内部设计元件 | 设计参数 | 数值 |

|---|---|---|

| 折流板 | 折流板厚度/mm | 5 |

| 折流板数量 | 4 | |

| 折流板①和③缺口弧度占整体弧度的比例 | 29% | |

| 折流板②和④缺口宽度占整体宽度的比例 | 28%、26% | |

| 进口折流板处间隙 | 进口处管板间隙/mm | 1.5 |

| 设计参数 | 数值 |

|---|---|

| 进出口集水箱高度/mm | 120 |

| 阶梯式隔板缺口弧度占整体弧度的比例 | 29%、54%、79% |

| 隔板数量 | 4 |

表3 异形仿生扇形隔板和阶梯式隔板换热器设计参数

Table 3 Design parameters of SSBHX-FA and SSBHX-LA

| 设计参数 | 数值 |

|---|---|

| 进出口集水箱高度/mm | 120 |

| 阶梯式隔板缺口弧度占整体弧度的比例 | 29%、54%、79% |

| 隔板数量 | 4 |

| 物理性质 | 数值 |

|---|---|

| ρ/(kg/m3) | 1025 |

| cp/(J/(kg·K)) | 3890 |

| λ/(W/(m·K)) | 0.634 |

| μ/(Pa·s) | 0.0008545 |

表4 壳侧流体的热物性参数

Table 4 Thermophysical parameters of shell side fluid

| 物理性质 | 数值 |

|---|---|

| ρ/(kg/m3) | 1025 |

| cp/(J/(kg·K)) | 3890 |

| λ/(W/(m·K)) | 0.634 |

| μ/(Pa·s) | 0.0008545 |

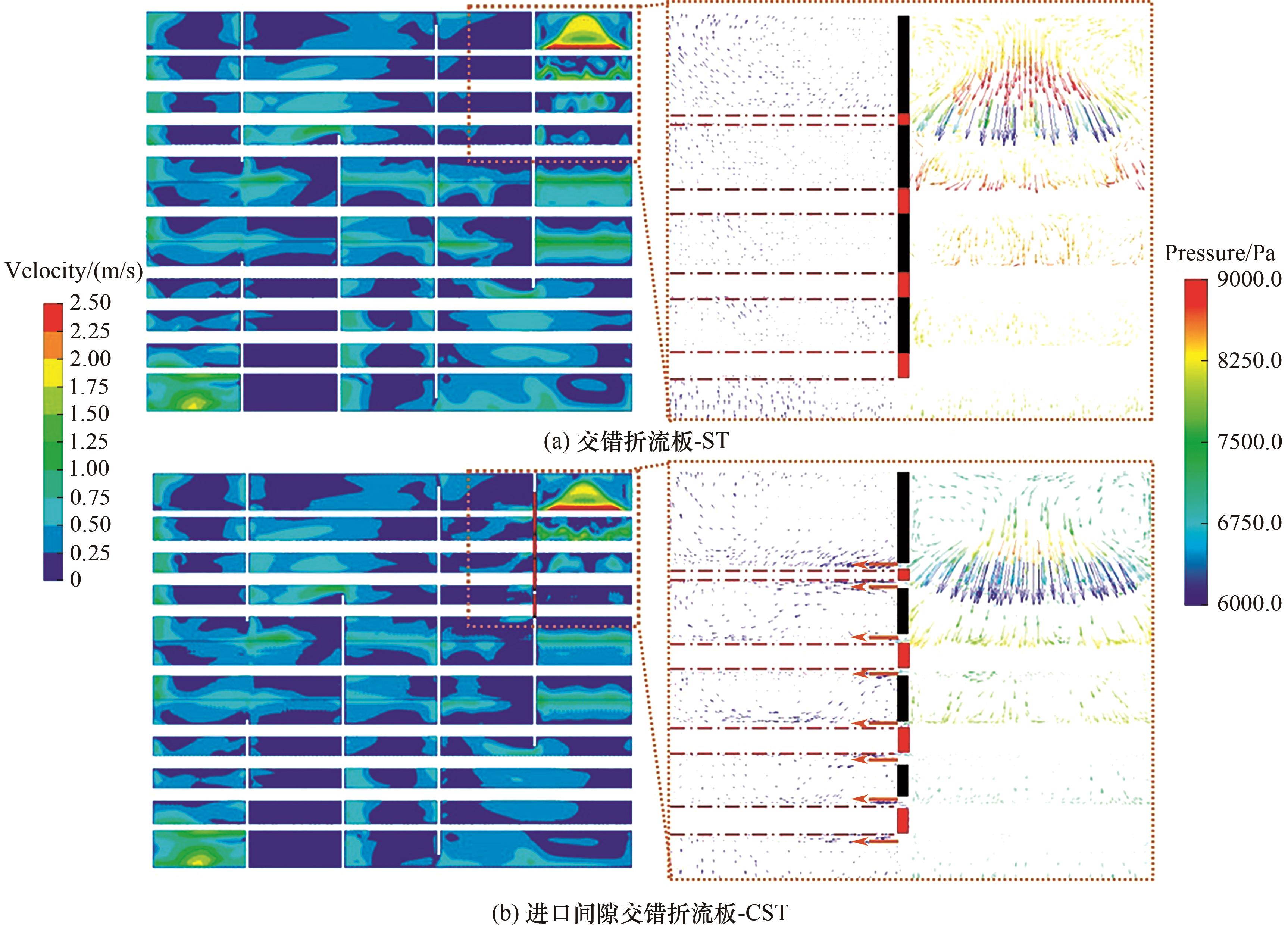

图6 异形仿生交错折流板和进口间隙折流板换热器壳侧某一截面速度分布与速度矢量叠加压力云图(v=2.0 m/s)

Fig.6 Shell side velocity distribution and vector superimposed pressure drop on a section of SSBHX-ST and SSBHX-CST (v = 2.0 m/s)

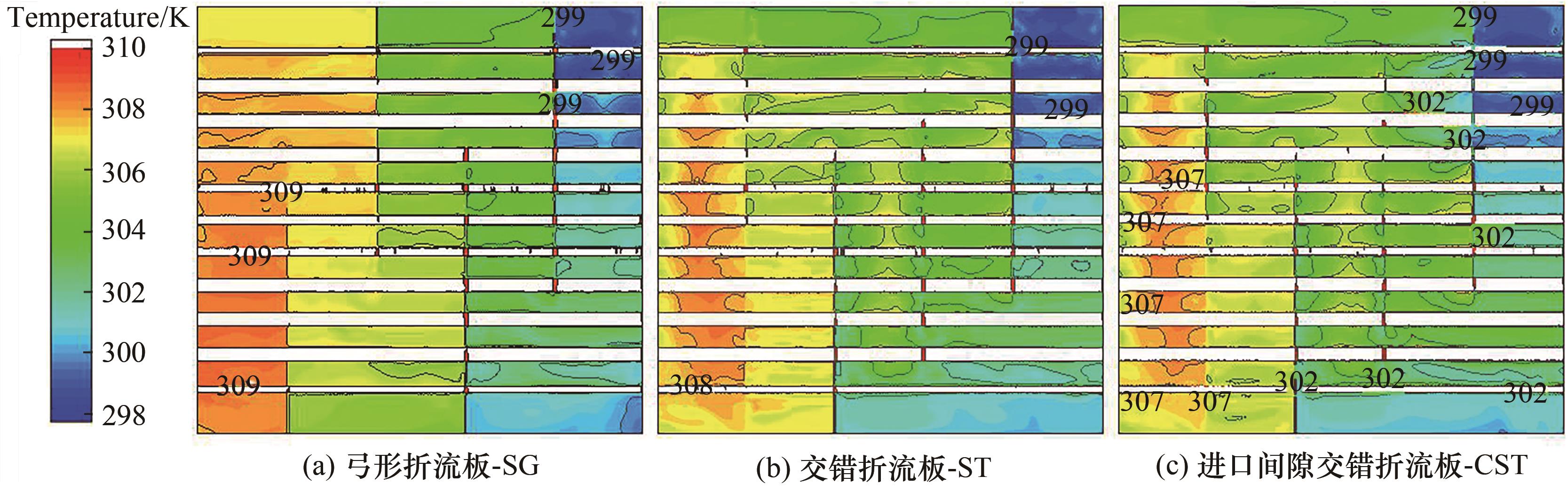

图13 异形仿生弓形折流板、交错折流板和进口间隙交错折流板换热器特定截面壳侧等温图(v=0.5 m/s)

Fig.13 Temperature contour of multi section combined shell side of SSBHX-SG, SSBHX-ST and SSBHX-CST (v = 0.5 m/s)

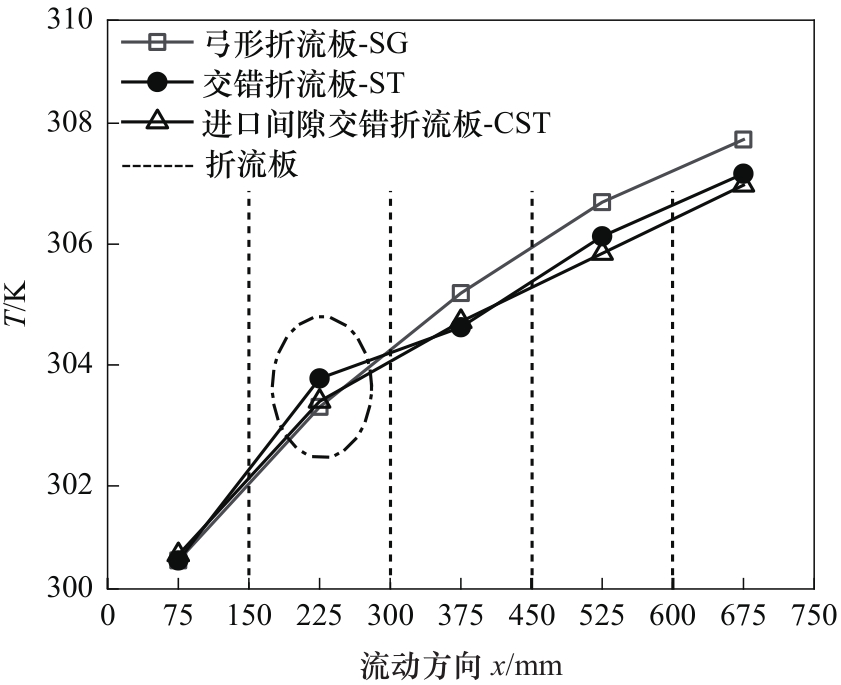

图14 异形仿生弓形折流板、交错折流板和进口间隙交错折流板换热器壳程各区域平均温度变化曲线(v=0.5 m/s)

Fig.14 Shell side average temperature curve of SSBHX-SG, SSBHX-ST and SSBHX-CST (v = 0.5 m/s)

| 1 | Duan Z Y, Shen F, Cao X, et al. Comprehensive effects of baffle configuration on the performance of heat exchanger with helical baffles[J]. Nuclear Engineering and Design, 2016, 300: 349-357. |

| 2 | Zhang J F, He Y L, Tao W Q. 3D numerical simulation on shell-and-tube heat exchangers with middle-overlapped helical baffles and continuous baffles(I): Numerical model and results of whole heat exchanger with middle-overlapped helical baffles[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5371-5380. |

| 3 | Jian W, Yang H Z, Wang S M, et al. Numerical investigation on baffle configuration improvement of the heat exchanger with helical baffles[J]. Energy Conversion and Management, 2015, 89: 438-448. |

| 4 | Cao X, Du T T, Liu Z, et al. Experimental and numerical investigation on heat transfer and fluid flow performance of sextant helical baffle heat exchangers[J]. International Journal of Heat and Mass Transfer, 2019, 142: 118437. |

| 5 | Gao B, Bi Q C, Nie Z S, et al. Experimental study of effects of baffle helix angle on shell-side performance of shell-and-tube heat exchangers with discontinuous helical baffles[J]. Experimental Thermal and Fluid Science, 2015, 68: 48-57. |

| 6 | Wen J, Gu X, Wang M M, et al. Multi-parameter optimization of shell-and-tube heat exchanger with helical baffles based on entransy theory[J]. Applied Thermal Engineering, 2018, 130: 804-813. |

| 7 | Dong C, Li D S, Zheng Y Q, et al. An efficient and low resistant circumferential overlap trisection helical baffle heat exchanger with folded baffles[J]. Energy Conversion and Management, 2016, 113: 143-152. |

| 8 | 刘秀峰, 张诗, 周志杰, 等. 换热器结构优化与换热性能评价指标研究[J]. 化工学报, 2020, 71: 98-105. |

| Liu X F, Zhang S, Zhou Z J, et al. Study on structure optimization of heat exchanger and evaluation index of heat transfer performance[J]. CIESC Journal, 2020, 71: 98-105. | |

| 9 | 曹兴, 杜文静, 程林. 连续螺旋折流板换热器流动与传热性能及熵产分析[J]. 化工学报, 2012, 63(8): 2375-2382. |

| Cao X, Du W J, Cheng L. Analyses on flow and heat transfer performance and entropy generation of heat exchanger with continuous helical baffles[J]. CIESC Journal, 2012, 63(8): 2375-2382. | |

| 10 | Wang Q W, Chen G D, Chen Q Y, et al. Review of improvements on shell-and-tube heat exchangers with helical baffles[J]. Heat Transfer Engineering, 2010, 31(10): 836-853. |

| 11 | Wang Y S, Liu Z C, Huang S Y, et al. Experimental investigation of shell-and-tube heat exchanger with a new type of baffles[J]. Heat and Mass Transfer, 2011, 47(7): 833-839. |

| 12 | Chen J, Zhao P B, Wang Q W, et al. Experimental investigation of shell-side performance and optimal design of shell-and-tube heat exchanger with different flower baffles[J]. Heat Transfer Engineering, 2021, 42(7): 613-626. |

| 13 | You Y H, Fan A W, Huang S Y, et al. Numerical modeling and experimental validation of heat transfer and flow resistance on the shell side of a shell-and-tube heat exchanger with flower baffles[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7561-7569. |

| 14 | Biçer N, Engin T, Yaşar H, et al. Design optimization of a shell-and-tube heat exchanger with novel three-zonal baffle by using CFD and Taguchi method[J]. International Journal of Thermal Sciences, 2020, 155: 106417. |

| 15 | Lei Y G, Li Y Z, Jing S L, et al. Design and performance analysis of the novel shell-and-tube heat exchangers with louver baffles[J]. Applied Thermal Engineering, 2017, 125: 870-879. |

| 16 | Yang S F, Chen Y P, Wu J F, et al. Investigation on shell side performance in half-cylindrical desuperheating zone of ladder type helical baffle heat exchangers[J]. Applied Thermal Engineering, 2020, 175: 115334. |

| 17 | Chen J, Lu X, Wang Q W, et al. Experimental investigation on thermal-hydraulic performance of a novel shell-and-tube heat exchanger with unilateral ladder type helical baffles[J]. Applied Thermal Engineering, 2019, 161: 114099. |

| 18 | Xiao J, Wang S M, Ye S P, et al. Experimental investigation on pre-heating technology of coal water slurry with different concentration in shell-and-tube heat exchangers with ladder-type fold baffles[J]. International Journal of Heat and Mass Transfer, 2019, 132: 1116-1125. |

| 19 | 古新, 罗元坤, 熊晓朝, 等. 扭转流换热器结构参数对流场和温度场的影响[J]. 化工学报, 2018, 69(8): 3390-3397. |

| Gu X, Luo Y K, Xiong X C, et al. Influence of twisty flow heat exchanger's structural parameters on flow field and temperature field[J]. CIESC Journal, 2018, 69(8): 3390-3397. | |

| 20 | 古新, 秦晓柯, 王永庆, 等. 倾斜折流栅式换热器壳程流体流动与传热特性[J]. 化工进展, 2017, 36(10): 3584-3589. |

| Gu X, Qin X K, Wang Y Q, et al. Research on fluid flow and heat transfer characteristics in shell side of inclined shutter baffle heat exchanger[J]. Chemical Industry and Engineering Progress, 2017, 36(10): 3584-3589. | |

| 21 | 孟芳. 螺旋折流板管壳式换热器的CFD模拟研究[D]. 天津: 天津大学, 2015. |

| Meng F. CFD simulation of shell-and-tube heat exchanger with helical baffles[D]. Tianjin: Tianjin University, 2015. | |

| 22 | 王英双, 张晓屿, 刘志春, 等. 花格板换热器的流动与传热[J]. 化工学报, 2012, 63: 99-106. |

| Wang Y S, Zhang X Y, Liu Z C, et al. Fluid flow and heat transfer study for flower baffle heat exchanger[J]. CIESC Journal, 2012, 63: 99-106. | |

| 23 | 陈康, 姚志崇, 周恩东, 等. 基于体积力的海水自流循环系统流速确定方法[J]. 中国舰船研究, 2019, 14(5): 70-76. |

| Chen K, Yao Z C, Zhou E D, et al. Body force-based method for determining flow velocity of sea water artesian circulating system [J]. Chinese Journal of Ship Research, 2019, 14(5): 70-76. | |

| 24 | 刘明明. 鲨鱼鳃部结构分析及仿生射流减阻特性研究[D]. 哈尔滨: 哈尔滨工程大学, 2014. |

| Liu M M. Structure analysis of shark gills and research on bionic jet drag reduction characteristic[D]. Harbin: Harbin Engineering University, 2014. | |

| 25 | 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会.热交换器:[S]. 北京: 中国标准出版社, 2015. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Heat exchangers: [S]. Beijing: Standards Press of China, 2015. | |

| 26 | 董其伍, 欧阳克, 刘敏珊, 等. 茹卡乌斯卡斯横掠错排管束实验模型的数值模拟[J]. 压力容器, 2010, 27(1): 21-26. |

| Dong Q W, Ouyang K, Liu M S, et al. Numerical investigation of fluid flow across tube bundles in Zukauskas experimental model[J]. Pressure Vessel Technology, 2010, 27(1): 21-26. | |

| 27 | 茹卡乌斯卡斯, A A. 换热器内的对流传热[M]. 马昌文, 居滋象, 肖宏才, 译. 北京: 科学出版社, 1986: 66-77,317-329. |

| Жукаускас А А. Convective Heat Transfer in Heat Exchanger[M]. Ma C W, Ju Z X, Xiao H C, trans. Beijing: Science Press, 1986: 66-77, 317-329. | |

| 28 | 赖利, 斯基罗. 化学海洋学[M]. 吴瑜端, 杨逸萍, 译.2版. 北京:海洋出版社, 1984: 555-564. |

| Riley J P, Skirrow G. Chemical Oceanography[M]. Wu Y D, Yang Y P, trans. 2nd ed. Beijing: Ocean Press, 1984: 555-564. | |

| 29 | Guo Z Y, Zhou S Q, Li Z X, et al. Theoretical analysis and experimental confirmation of the uniformity principle of temperature difference field in heat exchanger[J]. International Journal of Heat and Mass Transfer, 2002, 45(10): 2119-2127. |

| 30 | Webb R L. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design[J]. International Journal of Heat and Mass Transfer, 1981, 24(4): 715-726. |

| 31 | Wang X T, Zheng N B, Liu Z C, et al. Numerical analysis and optimization study on shell-side performances of a shell and tube heat exchanger with staggered baffles[J]. International Journal of Heat and Mass Transfer, 2018, 124: 247-259. |

| [1] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [2] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [8] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [9] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [10] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [11] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [12] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [13] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [14] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [15] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号