化工学报 ›› 2022, Vol. 73 ›› Issue (9): 3880-3894.DOI: 10.11949/0438-1157.20220456

收稿日期:2022-03-30

修回日期:2022-06-09

出版日期:2022-09-05

发布日期:2022-10-09

通讯作者:

童张法

作者简介:何瑞宁(1992—),男,博士研究生,mydayhe@foxmail.com

基金资助:

Ruining HE( ), Yun ZOU, Meng SHI, Yang LI, Jing XU, Zhangfa TONG(

), Yun ZOU, Meng SHI, Yang LI, Jing XU, Zhangfa TONG( )

)

Received:2022-03-30

Revised:2022-06-09

Online:2022-09-05

Published:2022-10-09

Contact:

Zhangfa TONG

摘要:

为使离子液体(ILs)在保持催化活性的前提下更易分离回收,减轻ILs的腐蚀,制备了固载ILs,并用于催化酯化反应合成乙酸乙酯(EtAc)。通过红外光谱、热失重、N2吸附-脱附、扫描电镜等对固载ILs进行表征分析,发现溶胶-凝胶(Sol-Gel)法比浸渍法能更有效地固载ILs于二氧化硅(SiO2)载体上,在催化乙酸乙醇酯化合成EtAc时催化效果较好。反应条件为酸醇比R0A∶E = 1,反应温度T在323.15~338.15 K范围内,催化剂与乙酸质量比xcat∶HAc在5%~15%范围内时,Sol-Gel法制备的[HSO3-BMIM][HSO4]/SiO2初始反应速率较快,反应30 min时乙酸转化率(XHAc)超过50%,达到平衡转化率(68%)的约70%。使用LHHW模型拟合[HSO3-BMIM][HSO4]/SiO2催化酯化反应的速率,结果表明该模型预测准确。重复性考察发现,[HSO3-BMIM][HSO4]/SiO2在前三次使用时的XHAc (t = 4 h)超过60%,经六次使用后有所下降。使用Sol-Gel法制备的固载ILs的催化活性和稳定性优于浸渍法,表明Sol-Gel法更适合用于制备固载ILs。

中图分类号:

何瑞宁, 邹昀, 石萌, 李洋, 徐晶, 童张法. 固载离子液体[HSO3-BMIM][HSO4]/SiO2的制备及其催化乙酸乙醇酯化反应的研究[J]. 化工学报, 2022, 73(9): 3880-3894.

Ruining HE, Yun ZOU, Meng SHI, Yang LI, Jing XU, Zhangfa TONG. Preparation of supported ionic liquid [HSO3-BMIM][HSO4]/SiO2 and its catalytic property in the esterification of acetic acid and ethanol[J]. CIESC Journal, 2022, 73(9): 3880-3894.

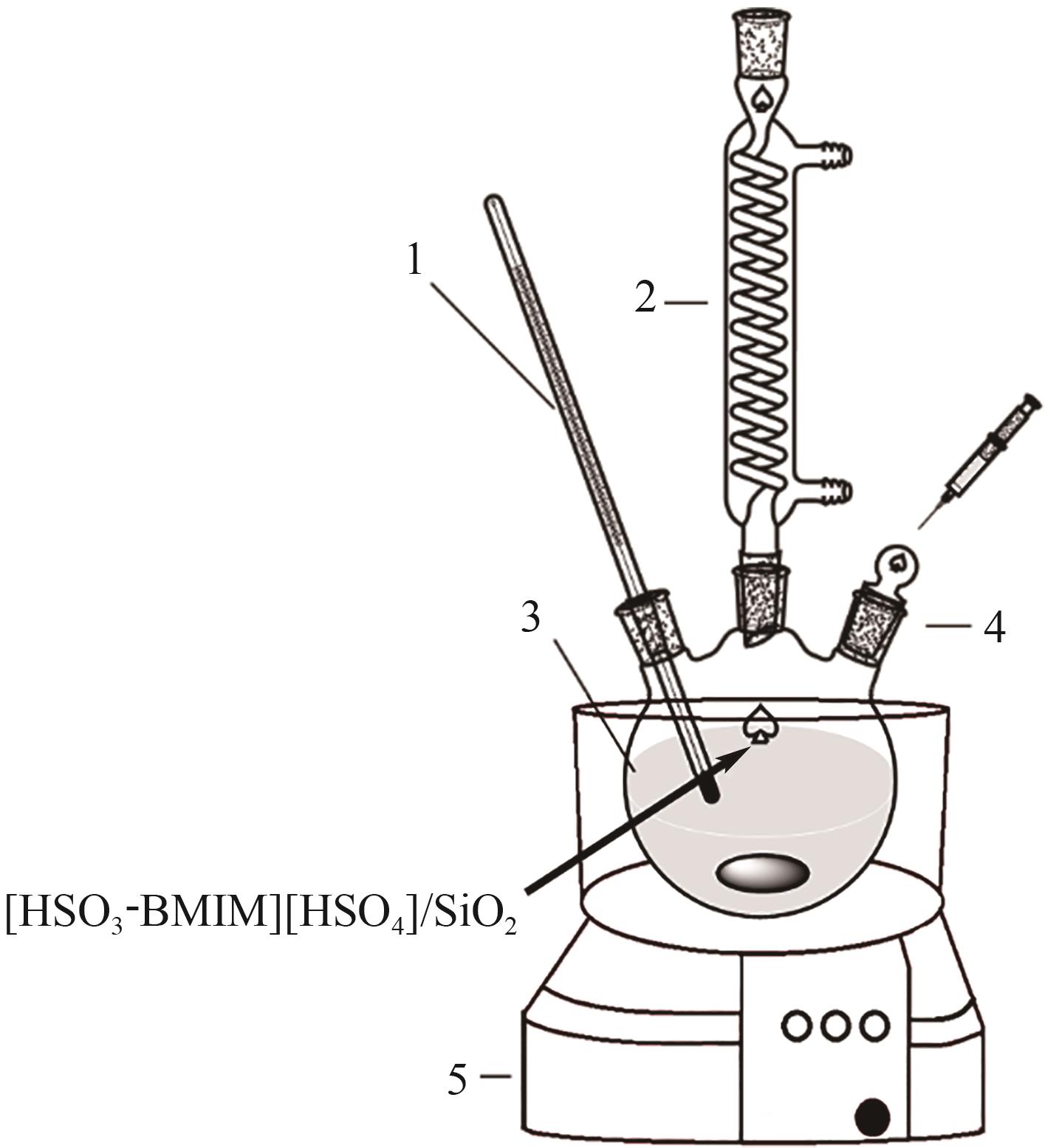

图2 固载ILs催化乙酸乙醇酯化反应装置1—温度计;2—冷凝管;3—三口烧瓶;4—取样口;5—恒温油浴锅

Fig.2 The experimental apparatus of the esterification of HAc and EtOH catalyzed by supported ILs

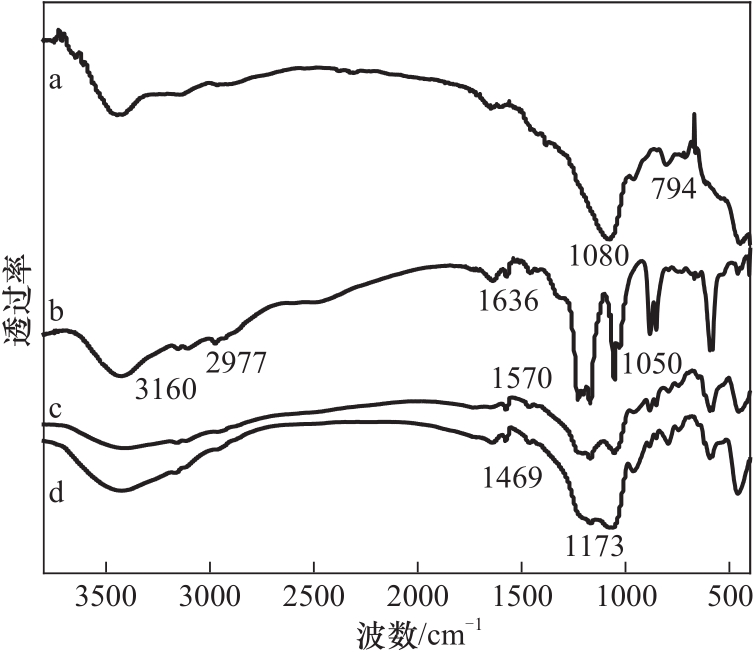

图3 催化剂红外谱图a—SiO2;b—[HSO3-BMIM][HSO4];c—[HSO3-BMIM][HSO4]/SiO2;d—重复使用6次的[HSO3-BMIM][HSO4]/SiO2

Fig.3 FT-IR spectra of catalystsa ─ SiO2; b ─[HSO3-BMIM][HSO4]; c ─[HSO3-BMIM][HSO4]/SiO2;d ─ reused [HSO3-BMIM][HSO4]/SiO2

| 样品 | SBET /(m2·g-1) | Dp/nm |

|---|---|---|

| 硅胶 | 640.66 | 2.51 |

| 无固载ILs的硅凝胶SiO2 | 533.81 | 2.07 |

| [HSO3-BMIM][HSO4]/SiO2 | 70.34 | 6.77 |

| reused [HSO3-BMIM][HSO4]/SiO2 | 340.65 | 5.36 |

表1 硅凝胶和固载ILs催化剂的BET比表面积分析和平均孔径

Table 1 BET surface properties of the supporters before and after immobilization

| 样品 | SBET /(m2·g-1) | Dp/nm |

|---|---|---|

| 硅胶 | 640.66 | 2.51 |

| 无固载ILs的硅凝胶SiO2 | 533.81 | 2.07 |

| [HSO3-BMIM][HSO4]/SiO2 | 70.34 | 6.77 |

| reused [HSO3-BMIM][HSO4]/SiO2 | 340.65 | 5.36 |

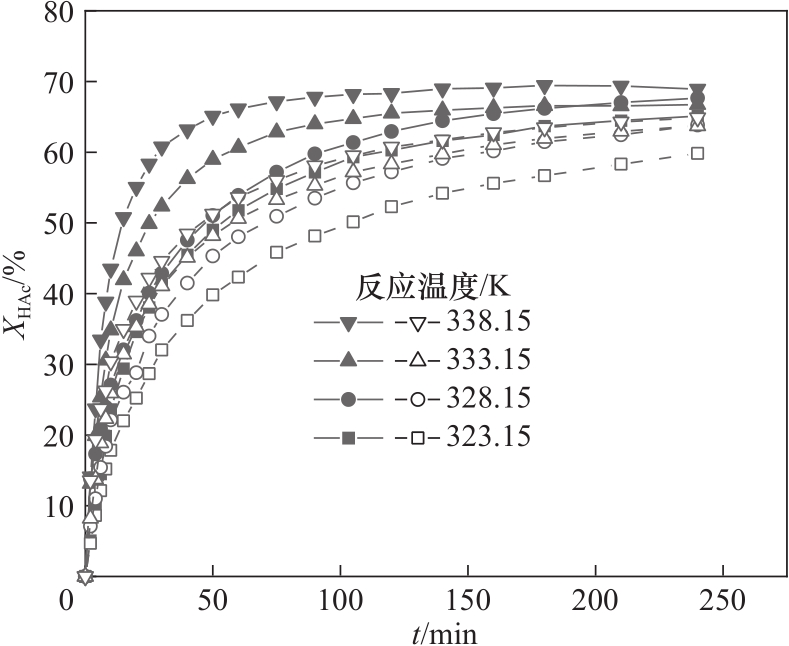

图8 反应温度对乙酸转化率的影响(xcat∶HAc =10%, R0A∶E = 1)实心点实线—[HSO3-BMIM][HSO4]/SiO2;空心点虚线—[HSO3-BMIM][HSO4]/Sil

Fig.8 Influence of reaction temperature on conversion of HAc at xcat∶HAc= 10%, R0A∶E=1 catalyzed by [HSO3-BMIM][HSO4]/SiO2 (solid lines) and [HSO3-BMIM][HSO4]/Sil (dash lines)

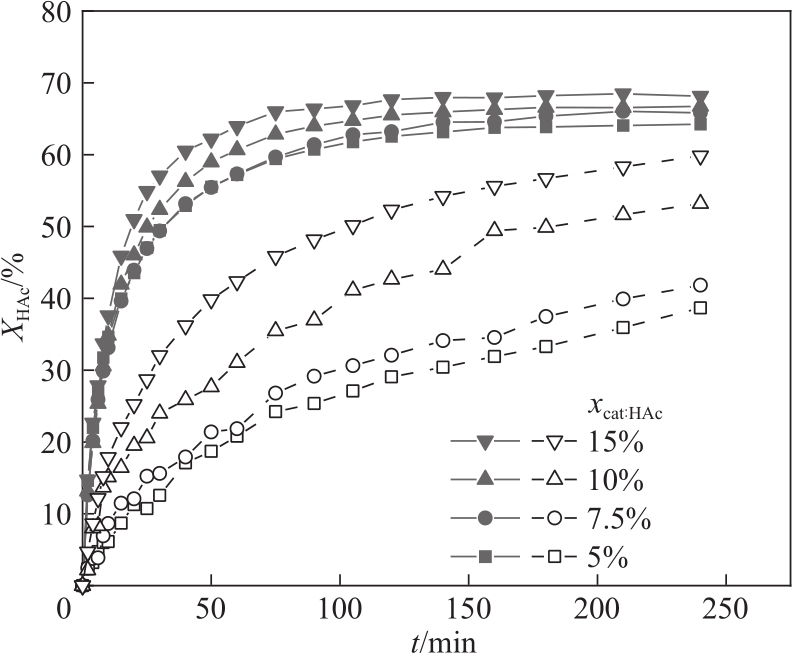

图9 催化剂用量对乙酸转化率的影响(T=333.15 K, R0A∶E = 1)实心点实线—[HSO3-BMIM][HSO4]/SiO2; 空心点虚线—[HSO3-BMIM][HSO4]/Sil

Fig.9 Influence of catalyst dosage on conversion of HAc at T= 333.15 K, R0A:E = 1 catalyzed by [HSO3-BMIM][HSO4]/SiO2 (solid lines) and [HSO3-BMIM][HSO4]/Sil (dash lines)

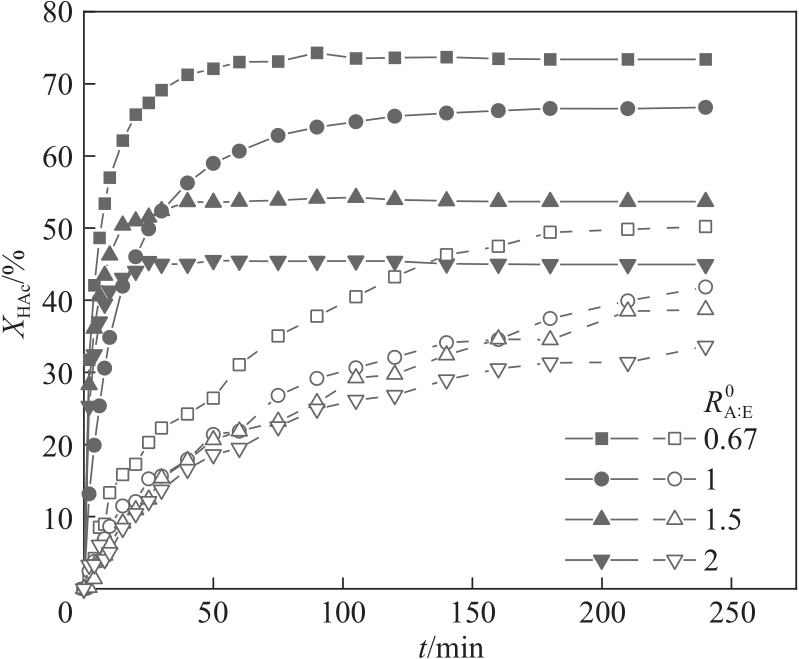

图10 初始反应物酸醇摩尔比对乙酸转化率的影响(T = 333.15 K, xcat∶HAc = 10%)实心点实线—[HSO3-BMIM][HSO4]/SiO2; 空心点虚线—[HSO3-BMIM][HSO4]/Sil

Fig.10 Influence of the mole ratio of HAc to EtOH on conversion of HAc at T = 333.15 K, xcat∶HAc = 10% catalyzed by [HSO3-BMIM][HSO4]/SiO2 (solid lines) and [HSO3-BMIM][HSO4]/Sil (dash lines)

| 样品 | rL /%(mass) |

|---|---|

| [HSO3-BMIM][HSO4]/SiO2 | 45.06 |

| [HSO3-BMIM][HSO4]/Sil | 27.19 |

| 6th reused [HSO3-BMIM][HSO4]/SiO2 | 22.82 |

| 6th reused [HSO3-BMIM][HSO4]/Sil | 20.91 |

表 2 固载前后载体对ILs的固载率

Table 2 The immobilization yield of ILs/SiO2 and ILs/Sil

| 样品 | rL /%(mass) |

|---|---|

| [HSO3-BMIM][HSO4]/SiO2 | 45.06 |

| [HSO3-BMIM][HSO4]/Sil | 27.19 |

| 6th reused [HSO3-BMIM][HSO4]/SiO2 | 22.82 |

| 6th reused [HSO3-BMIM][HSO4]/Sil | 20.91 |

| 催化剂 | 不锈钢薄片 表面积S/cm2 | 质量 流失/g | 腐蚀速率/ (g·m-2·h-1) |

|---|---|---|---|

| [HSO3-BMIM][HSO4]/SiO2 | 21.40 | 0.016 | 1.22 |

| [HSO3-BMIM][HSO4] | 22.22 | 0.120 | 10.03 |

| 98%浓硫酸 | 19.24 | 0.240 | 22.77 |

表3 固载ILs腐蚀性测试

Table 3 Intensity of corrosion of [HSO3-BMIM][HSO4]/SiO2,[HSO3-BMIM][HSO4] and H2SO4

| 催化剂 | 不锈钢薄片 表面积S/cm2 | 质量 流失/g | 腐蚀速率/ (g·m-2·h-1) |

|---|---|---|---|

| [HSO3-BMIM][HSO4]/SiO2 | 21.40 | 0.016 | 1.22 |

| [HSO3-BMIM][HSO4] | 22.22 | 0.120 | 10.03 |

| 98%浓硫酸 | 19.24 | 0.240 | 22.77 |

| 参数 | 数值 |

|---|---|

| A+0/(L∙mol-1∙min-1) | 845.12 |

| Ea+/( J∙mol-1) | 27007.51 |

| A-0/(L∙mol-1∙min-1) | 673.73 |

| Ea-/(J∙mol-1) | 30000.11 |

| kEtOH/(L∙mol-1) | 10.01 |

| ΔHEtOH/(J∙mol-1) | 27993.08 |

| 32.70 | |

| Δ | 9346.72 |

| MASE | 3.153×10-4 |

表4 LHHW模型动力学参数拟合结果

Table 4 Parameters of the kinetic equations based on LHHW models

| 参数 | 数值 |

|---|---|

| A+0/(L∙mol-1∙min-1) | 845.12 |

| Ea+/( J∙mol-1) | 27007.51 |

| A-0/(L∙mol-1∙min-1) | 673.73 |

| Ea-/(J∙mol-1) | 30000.11 |

| kEtOH/(L∙mol-1) | 10.01 |

| ΔHEtOH/(J∙mol-1) | 27993.08 |

| 32.70 | |

| Δ | 9346.72 |

| MASE | 3.153×10-4 |

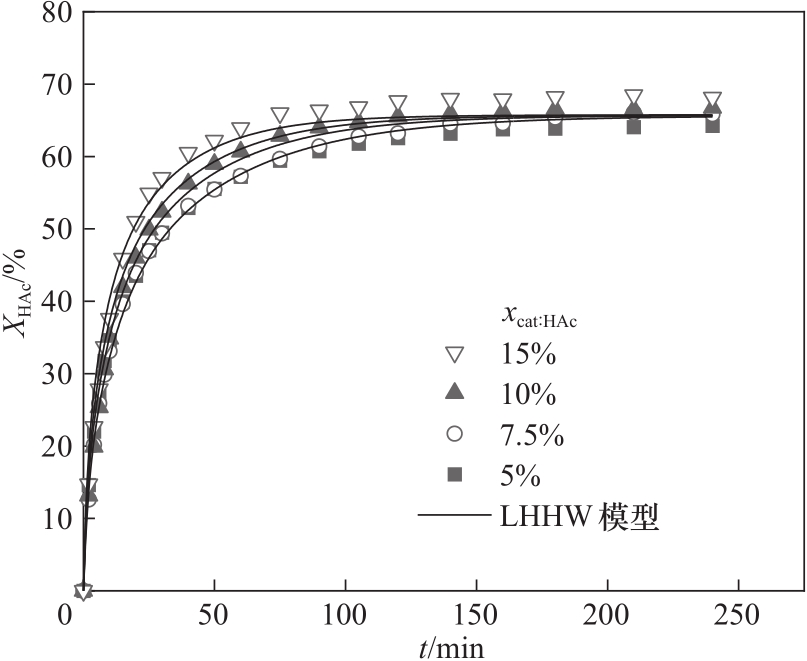

图12 LHHW模型对实验催化剂用量下乙酸转化率的预测结果(T= 333.15 K, R0A∶E = 1)

Fig.12 Data fitting results of LHHW model on XHAc at experimental catalyst dosage (T= 333.15 K, R0A∶E = 1)

| 1 | Li Y, Zou Y, Xu H, et al. Preparation of n-amyl acetate via esterification of acetic acid and n-amyl alcohol using [HSO3 -pmim][HSO4]/SiO2 as catalyst: catalyst preparation, characterization and reaction kinetics[J]. Chemical Engineering Journal, 2021, 410: 128282. |

| 2 | Fan L, Xu B H, Li J, et al. Kinetic studies on both synthesis of methacrolein catalyzed by an ionic liquid and catalyst deactivation[J]. Industrial & Engineering Chemistry Research, 2021, 60(15): 5411-5420. |

| 3 | He R N, Dong Y B, Zou Y, et al. Simulation and optimization of reactive distillation for the production of ethyl acetate using[BMIM]HSO4 as catalyst[J]. Chemical Engineering Research and Design, 2020, 161: 218-231. |

| 4 | Deng Q L, Tran N N, Razi Asrami M, et al. Ionic liquid/water continuous-flow system with compartmentalized spaces for automatic product purification of biotransformation with enzyme recycling[J]. Industrial & Engineering Chemistry Research, 2020, 59(48): 21001-21011. |

| 5 | Jiang Y Y, Guo C, Xia H S, et al. Magnetic nanoparticles supported ionic liquids for lipase immobilization: enzyme activity in catalyzing esterification[J]. Journal of Molecular Catalysis B: Enzymatic, 2009, 58(1/2/3/4): 103-109. |

| 6 | Mehnert C P, Cook R A, Dispenziere N C, et al. Supported ionic liquid catalysis—a new concept for homogeneous hydroformylation catalysis[J]. Journal of the American Chemical Society, 2002, 124(44): 12932-12933. |

| 7 | Virtanen P, Karhu H, Kordas K, et al. The effect of ionic liquid in supported ionic liquid catalysts (SILCA) in the hydrogenation of α, β-unsaturated aldehydes[J]. Chemical Engineering Science, 2007, 62(14): 3660-3671. |

| 8 | Yamakawa S, Wada K, Hidaka M, et al. Chiral liquid-crystalline ionic liquid systems useful for electrochemical polymerization that affords helical conjugated polymers[J]. Advanced Functional Materials, 2019, 29(12): 1806592. |

| 9 | Joni J, Haumann M, Wasserscheid P. Development of a supported ionic liquid phase (SILP) catalyst for slurry-phase Friedel-Crafts alkylations of cumene[J]. Advanced Synthesis & Catalysis, 2009, 351(3): 423-431. |

| 10 | 唐苏苏, 胡燚, 余定华, 等. 功能化离子液体修饰的SBA-15固定化Burkholderia cepacia脂肪酶[J]. 催化学报, 2012, 33(9): 1565-1571. |

| Tang S S, Hu Y, Yu D H, et al. Immobilization of Burkholderia cepacia lipase on functionalized ionic liquids modified mesoporous silica SBA-15[J]. Chinese Journal of Catalysis, 2012, 33(9): 1565-1571. | |

| 11 | 岳东敏, 张欠之, 孙德, 等. PVA/SO4 2--AAO催化-渗透汽化双功能复合膜合成乙酸乙酯[J]. 化工学报, 2018, 69(6): 2775-2781. |

| Yue D M, Zhang Q Z, Sun D, et al. Preparation and properties of PVA/SO4 2--AAO catalytic-pervaporation difunctional membrane for ethyl acetate synthesis[J]. CIESC Journal, 2018, 69(6): 2775-2781. | |

| 12 | Hernández-Fernández F J, de los Ríos A P, Tomás-Alonso F, et al. Preparation of supported ionic liquid membranes: influence of the ionic liquid immobilization method on their operational stability[J]. Journal of Membrane Science, 2009, 341(1/2): 172-177. |

| 13 | de Castro C, Primo J, Corma A. Heteropolyacids and large-pore zeolites as catalysts in acylation reactions using α, β-unsaturated organic acids as acylating agents[J]. Journal of Molecular Catalysis A: Chemical, 1998, 134(1/2/3): 215-222. |

| 14 | Schmidt C, Glück T, Schmidt-Naake G. Modification of nafion membranes by impregnation with ionic liquids[J]. Chemical Engineering & Technology, 2008, 31(1): 13-22. |

| 15 | Xie Y, Zhang Z F, Jiang T, et al. CO2 cycloaddition reactions catalyzed by an ionic liquid grafted onto a highly cross-linked polymer matrix[J]. Angewandte Chemie (International Ed. in English), 2007, 46(38): 7255-7258. |

| 16 | Valkenberg M H, de Castro C, Hölderich W F. Immobilisation of ionic liquids on solid supports[J]. Green Chemistry, 2002, 4(2): 88-93. |

| 17 | Zhou H C, Yang L R, Li W, et al. Immobilizing penicillin G acylase using silica-supported ionic liquids: the effects of ionic liquid loadings[J]. Industrial & Engineering Chemistry Research, 2012, 51(40): 13173-13181. |

| 18 | Shi F, Zhang Q H, Li D M, et al. Silica-gel-confined ionic liquids: a new attempt for the development of supported nanoliquid catalysis[J]. Chemistry - A European Journal, 2005, 11(18): 5279-5288. |

| 19 | Xie W L, Wan F. Immobilization of polyoxometalate-based sulfonated ionic liquids on UiO-66-2COOH metal-organic frameworks for biodiesel production via one-pot transesterification-esterification of acidic vegetable oils[J]. Chemical Engineering Journal, 2019, 365: 40-50. |

| 20 | Gruttadauria M, Riela S, Aprile C, et al. Supported ionic liquids. New recyclable materials for the L-proline-catalyzed aldol reaction[J]. Advanced Synthesis & Catalysis, 2006, 348(1/2): 82-92. |

| 21 | Xun S H, Zhu W S, Chang Y H, et al. Synthesis of supported SiW12O40-based ionic liquid catalyst induced solvent-free oxidative deep-desulfurization of fuels[J]. Chemical Engineering Journal, 2016, 288: 608-617. |

| 22 | 甘攀学, 张涛, 唐盛伟. 酸性离子液体功能化MCM-36分子筛用于催化合成乙酸乙酯[J]. 石油化工, 2016, 45(10): 1172-1179. |

| Gan P X, Zhang T, Tang S W. Synthesis of ethyl acetate catalyzed by MCM-36 molecular sieve functionalized with acidic ionic liquids[J]. Petrochemical Technology, 2016, 45(10): 1172-1179. | |

| 23 | Muhammad Y, Rashid H U, Subhan S, et al. Boosting the hydrodesulfurization of dibenzothiophene efficiency of Mn decorated (Co/Ni)-Mo/Al2O3 catalysts at mild temperature and pressure by coupling with phosphonium based ionic liquids[J]. Chemical Engineering Journal, 2019, 375: 121957. |

| 24 | Zhao H. Methods for stabilizing and activating enzymes in ionic liquids — a review[J]. Journal of Chemical Technology & Biotechnology, 2010, 85(7): 891-907. |

| 25 | Hartmann M, Jung D. Biocatalysis with enzymes immobilized on mesoporous hosts: the status quo and future trends[J]. J. Mater. Chem., 2010, 20(5): 844-857. |

| 26 | He R N, Zou Y, Muhammad Y, et al. Study on the intensification of reaction kinetics and reactive distillation for the esterification of N-butyl acetate using [HSO3-BMIM][HSO4] as a high-efficiency ionic liquid catalyst[J]. Industrial & Engineering Chemistry Research, 2021, 60(35): 12847-12863. |

| 27 | He R N, Zou Y, Dong Y B, et al. Kinetic study and process simulation of esterification of acetic acid and ethanol catalyzed by [HSO3-bmim][HSO4][J]. Chemical Engineering Research and Design, 2018, 137: 235-245. |

| 28 | 胡甜甜, 赵地顺, 武宇, 等. 醚基功能化离子液体催化合成乙酸正丁酯[J]. 化工学报, 2017, 68(1): 136-145. |

| Hu T T, Zhao D S, Wu Y, et al. Synthesis of n-butyl acetate by ether-functionalized ionic liquid[J]. CIESC Journal, 2017, 68(1): 136-145. | |

| 29 | Miao J M, Wan H, Guan G F. Synthesis of immobilized Brønsted acidic ionic liquid on silica gel as heterogeneous catalyst for esterification[J]. Catalysis Communications, 2011, 12(5): 353-356. |

| 30 | Zhen B, Jiao Q Z, Zhang Y P, et al. Acidic ionic liquid immobilized on magnetic mesoporous silica: preparation and catalytic performance in esterification[J]. Applied Catalysis A: General, 2012, 445/446: 239-245. |

| 31 | 沈忠权, 余锡孟, 陈纪忠. 新型磺化竹炭材料催化酯化反应[J]. 化工学报, 2015, 66(8): 3072-3077. |

| Shen Z Q, Yu X M, Chen J Z. Esterification reactions catalyzed by novel sulfonated carbon material derived from bamboo[J]. CIESC Journal, 2015, 66(8): 3072-3077. | |

| 32 | 廖安平, 蓝平, 李媚, 等. 流化催化精馏制备乙酸乙酯研究[J]. 化学工程, 2000, 28(6): 19-21, 33. |

| Liao A P, Lan P, Li M, et al. Synthesis of acetic ether using fluidizing catalytic reaction rectification[J]. Chemical Engineering (China), 2000, 28(6): 19-21, 33. | |

| 33 | 廖安平, 蓝平, 周桂, 等. 催化反应精馏技术连续制备乙酸乙酯[J]. 现代化工, 1997, 17(9): 25-27. |

| Liao A P, Lan P, Zhou G, et al. Synthesis of ethyl acetate using catalytic reaction distillation[J]. Modern Chemical Industry, 1997, 17(9): 25-27. | |

| 34 | Skoda-Földes R. The use of supported acidic ionic liquids in organic synthesis[J]. Molecules (Basel, Switzerland), 2014, 19(7): 8840-8884. |

| 35 | 徐浩, 李洋, 夏成康, 等. 吡啶硫酸氢盐离子液体催化甘油与乙酸酯化反应动力学[J]. 化工学报, 2020, 71(11): 5178-5187. |

| Xu H, Li Y, Xia C K, et al. Kinetics of esterification of glycerol with acetic acid catalyzed by pyridine bisulfate ionic liquid[J]. CIESC Journal, 2020, 71(11): 5178-5187. | |

| 36 | 夏成康, 徐浩, 何瑞宁, 等. 离子液体催化乙酸和乙醇酯化反应动力学的分析[J]. 高校化学工程学报, 2021, 35(6): 1027-1034. |

| Xia C K, Xu H, He R N, et al. Kinetic analysis of acetic acid and ethanol esterification catalyzed by ionic liquids[J]. Journal of Chemical Engineering of Chinese Universities, 2021, 35(6): 1027-1034. | |

| 37 | Brenna S, Posset T, Furrer J, et al. 14N NMR and two-dimensional suspension 1H and 13C HRMAS NMR spectroscopy of ionic liquids immobilized on silica[J]. Chemistry - A European Journal, 2006, 12(10): 2880-2888. |

| 38 | 魏作君, 李艳, 李斐瑾, 等. 固定化Brönsted酸性离子液体催化酯化反应[J]. 化工学报, 2009, 60(6): 1452-1458. |

| Wei Z J, Li Y, Li F J, et al. Catalytic esterification reactions over immobilized Brönsted ionic liquid[J]. CIESC Journal, 2009, 60(6): 1452-1458. | |

| 39 | 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 不锈钢5%硫酸腐蚀试验方法: [S]. 北京: 中国标准出版社, 2016. |

| General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Test method for stainless steels in 5% sulfuric acid: [S]. Beijing: Standards Press of China, 2016. | |

| 40 | Tao D J, Wu Y T, Zhou Z, et al. Kinetics for the esterification reaction of n-butanol with acetic acid catalyzed by noncorrosive Brønsted acidic ionic liquids[J]. Industrial & Engineering Chemistry Research, 2011, 50(4): 1989-1996. |

| 41 | Wang Y N, Lou W J, Wang X B. A green way to synthesize lubricating ester oils: the esterification of pentaerythrotol with fatty acids at stoichiometric ratio over [BHSO3MMIm]+[HSO4]-/SiO2 [J]. Catalysis Communications, 2018, 111: 21-25. |

| 42 | 胡晶晶, 赵地顺, 胡甜甜, 等. SBA-15固载酸性离子液体催化酯化反应性能[J]. 化工学报, 2016, 67(5): 1907-1914. |

| Hu J J, Zhao D S, Hu T T, et al. Synthesis and performance of heterogeneous catalyst of immobilized acidic ionic liquid on SBA-15 for esterification[J]. CIESC Journal, 2016, 67(5): 1907-1914. | |

| 43 | 安华良, 田金萍, 赵新强, 等. SiO2固载磺酸功能化离子液体的制备及其催化合成4, 4'-二氨基二苯甲烷[J]. 化工学报, 2015, 66(S1): 171-179. |

| An H L, Tian J P, Zhao X Q, et al. Preparation of silica-immobilized SO3H-functionalized ionic liquids and its catalytic activity in reaction of 4, 4'-methylenedianiline synthesis[J]. CIESC Journal, 2015, 66(S1): 171-179. | |

| 44 | Haumann M, Schönweiz A, Breitzke H, et al. Solid-state NMR investigations of supported ionic liquid phase water-gas shift catalysts: ionic liquid film distribution vs. catalyst performance[J]. Chemical Engineering & Technology, 2012, 35(8): 1421-1426. |

| 45 | Ma X X, Wang T T, Zhang M N, et al. Heteropoly acid supported on Cu-doped three-dimensionally ordered macroporous SiO2 as efficient catalyst for the selective oxidation of methacrolein[J]. Catalysis Letters, 2018, 148(2): 660-670. |

| 46 | 廖安平, 张雷, 蓝丽红, 等. 强酸性离子交换树脂催化合成乙酸乙酯动力学[J]. 化学反应工程与工艺, 2008, 24(4): 363-367. |

| Liao A P, Zhang L, Lan L H, et al. Kinetics of synthesis of ethyl acetate over strong acid ion exchange resin catalyst[J]. Chemical Reaction Engineering and Technology, 2008, 24(4): 363-367. |

| [1] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [2] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [3] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [4] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [5] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [6] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [7] | 王俐智, 杭钱程, 郑叶玲, 丁延, 陈家继, 叶青, 李进龙. 离子液体萃取剂萃取精馏分离丙酸甲酯+甲醇共沸物[J]. 化工学报, 2023, 74(9): 3731-3741. |

| [8] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [9] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [10] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [11] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [12] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [13] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [14] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [15] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号