化工学报 ›› 2021, Vol. 72 ›› Issue (12): 6241-6253.DOI: 10.11949/0438-1157.20210871

莫晗旸1,2( ),雍玉梅2(

),雍玉梅2( ),张广积2,于康2,陈文强2,杨超1,2

),张广积2,于康2,陈文强2,杨超1,2

收稿日期:2021-06-28

修回日期:2021-08-30

出版日期:2021-12-05

发布日期:2021-12-22

通讯作者:

雍玉梅

作者简介:莫晗旸(1994—),男,博士研究生, 基金资助:

Hanyang MO1,2( ),Yumei YONG2(

),Yumei YONG2( ),Guangji ZHANG2,Kang YU2,Wenqiang CHEN2,Chao YANG1,2

),Guangji ZHANG2,Kang YU2,Wenqiang CHEN2,Chao YANG1,2

Received:2021-06-28

Revised:2021-08-30

Online:2021-12-05

Published:2021-12-22

Contact:

Yumei YONG

摘要:

为了改善滴流床用的内卷吸型气液分配器的液体分散差的现象,提出了一种文丘里卷吸型气液分配器,并对其结构参数进行了参数化研究,定量认识卷吸型分配器的结构参数对其气液分配性能的影响。在冷态实验装置上进行了文丘里卷吸型气液分配器性能实验,建立了耦合群体平衡模型的欧拉-欧拉两相流模型,数值模拟了文丘里卷吸型气液分配器气液两相分配流动过程。冷模实验结合数值模拟,系统性考察了各结构参数对卷吸型气液分配器的液体分布均匀性、喷淋半径以及压降的影响。结果表明,采用具备缩-扩结构的文丘里管作为降液管能够有效提升卷吸型分配器的分布均匀度和喷淋半径,并显著降低压降。通过正交试验,获得了主要结构参数与分配性能的相关性,给出了结构参数与性能指标的经验关联式。降液管的扩张段是改善液体分配性能的关键结构,其扩张角为30°时液体分配性能最好。

中图分类号:

莫晗旸, 雍玉梅, 张广积, 于康, 陈文强, 杨超. 文丘里卷吸型气液分配器液体分配性能的结构参数研究[J]. 化工学报, 2021, 72(12): 6241-6253.

Hanyang MO, Yumei YONG, Guangji ZHANG, Kang YU, Wenqiang CHEN, Chao YANG. Study on the effects of structural parameters of bubble-cap distributor with Venturi downcomer on the liquid distribution performance[J]. CIESC Journal, 2021, 72(12): 6241-6253.

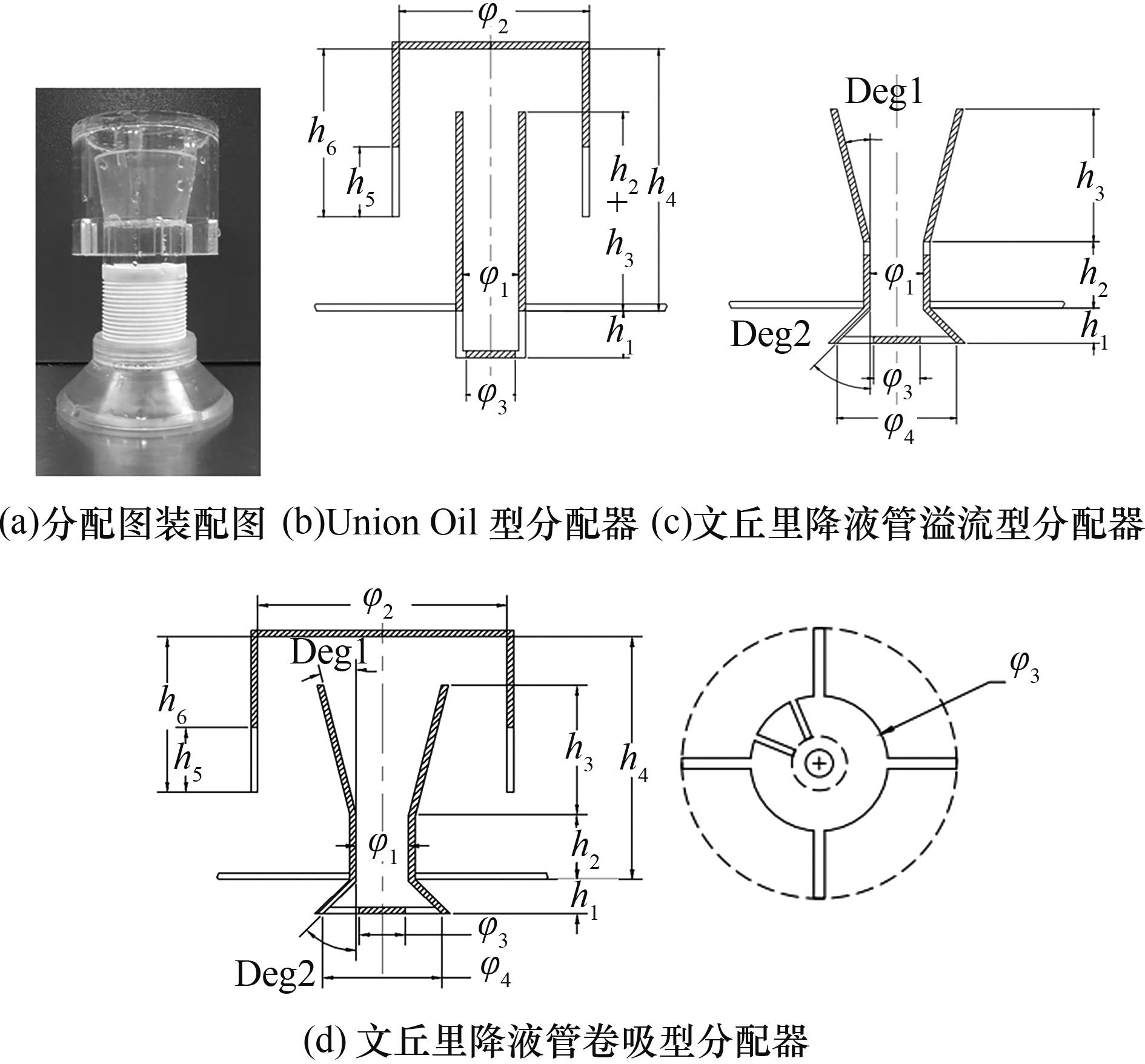

图2 三种类型的气液分配器实验装备图结构示意图φ1—降液管直径;φ2—泡帽直径;φ3—碎液板直径;φ4—降液管扩张段直径;h1—降液管扩张高度;h2—降液管喉管高度;h3—降液管缩径段高度;h4—分配器总高度;h5—条缝高度;h6—泡帽高度;Deg1—缩径角;Deg2—扩张角

Fig.2 Schematic of three types of G-L distributor

| φ1/mm | φ2/mm | φ3/mm | φ4/mm | h1/mm | h2/mm | h3/mm | h4/mm | ns | w | h5/mm | h6/mm | Deg1/(°) | Deg2/(°) | Ug/(m3/h) | Ul/(m3/h) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 50 | 27 | 53 | 20 | 29 | 29 | 66 | 6 | 3 | 16 | 65 | 10 | 45 | 18.0000 | 0.1522 |

表1 气液分配器标准结构和工况参数

Table 1 Standard structural and operation parameters of G-L distributor

| φ1/mm | φ2/mm | φ3/mm | φ4/mm | h1/mm | h2/mm | h3/mm | h4/mm | ns | w | h5/mm | h6/mm | Deg1/(°) | Deg2/(°) | Ug/(m3/h) | Ul/(m3/h) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 50 | 27 | 53 | 20 | 29 | 29 | 66 | 6 | 3 | 16 | 65 | 10 | 45 | 18.0000 | 0.1522 |

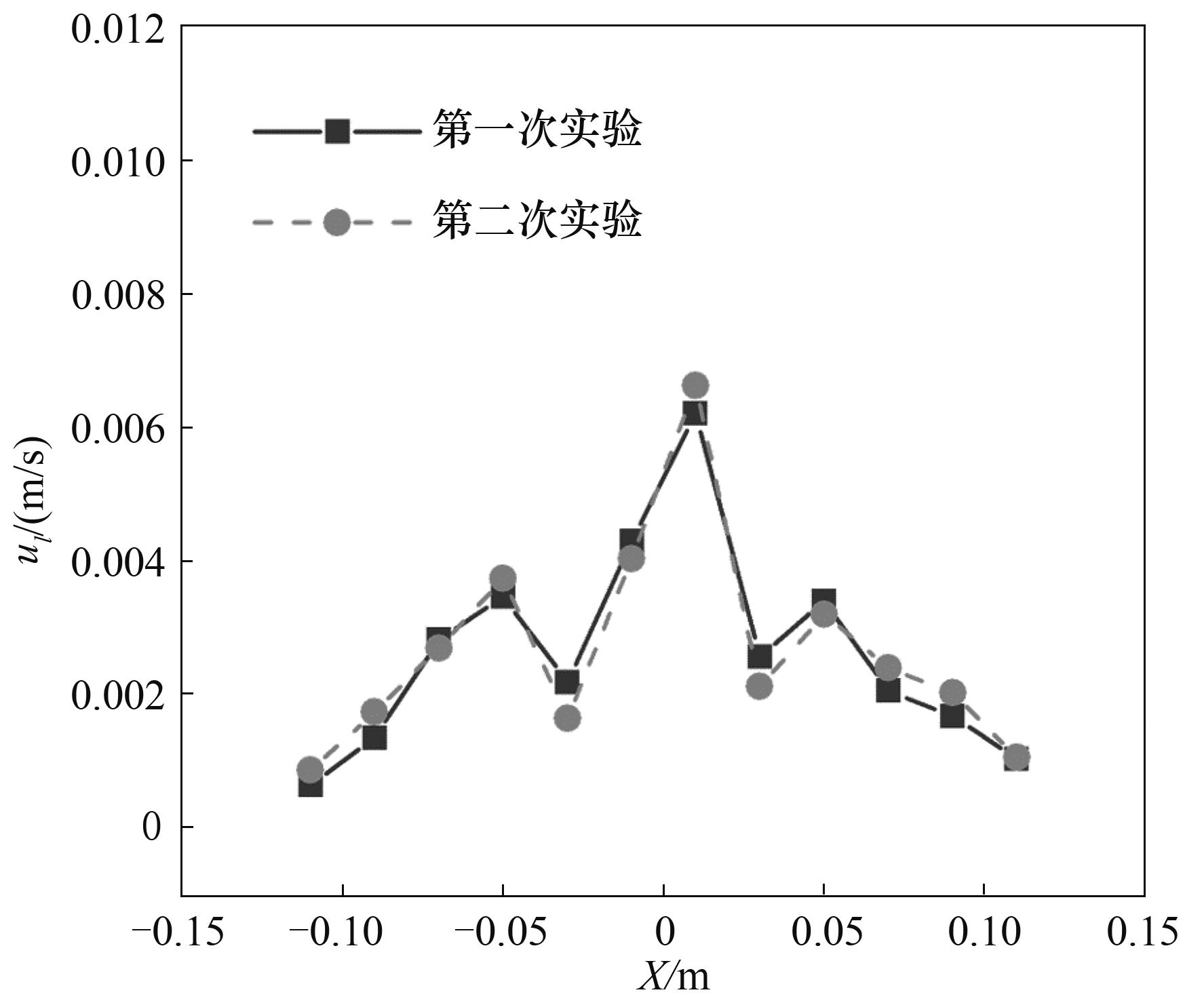

图3 实验可重复性验证(新型分配器, φ1=30 mm, Ug=18 m3/h, Ul=0.1522 m3/h)

Fig.3 Validation on repeatability of cold-flow model experiment (new G-L distributor, φ1=30 mm,Ug=18 m3/h, Ul=0.1522 m3/h)

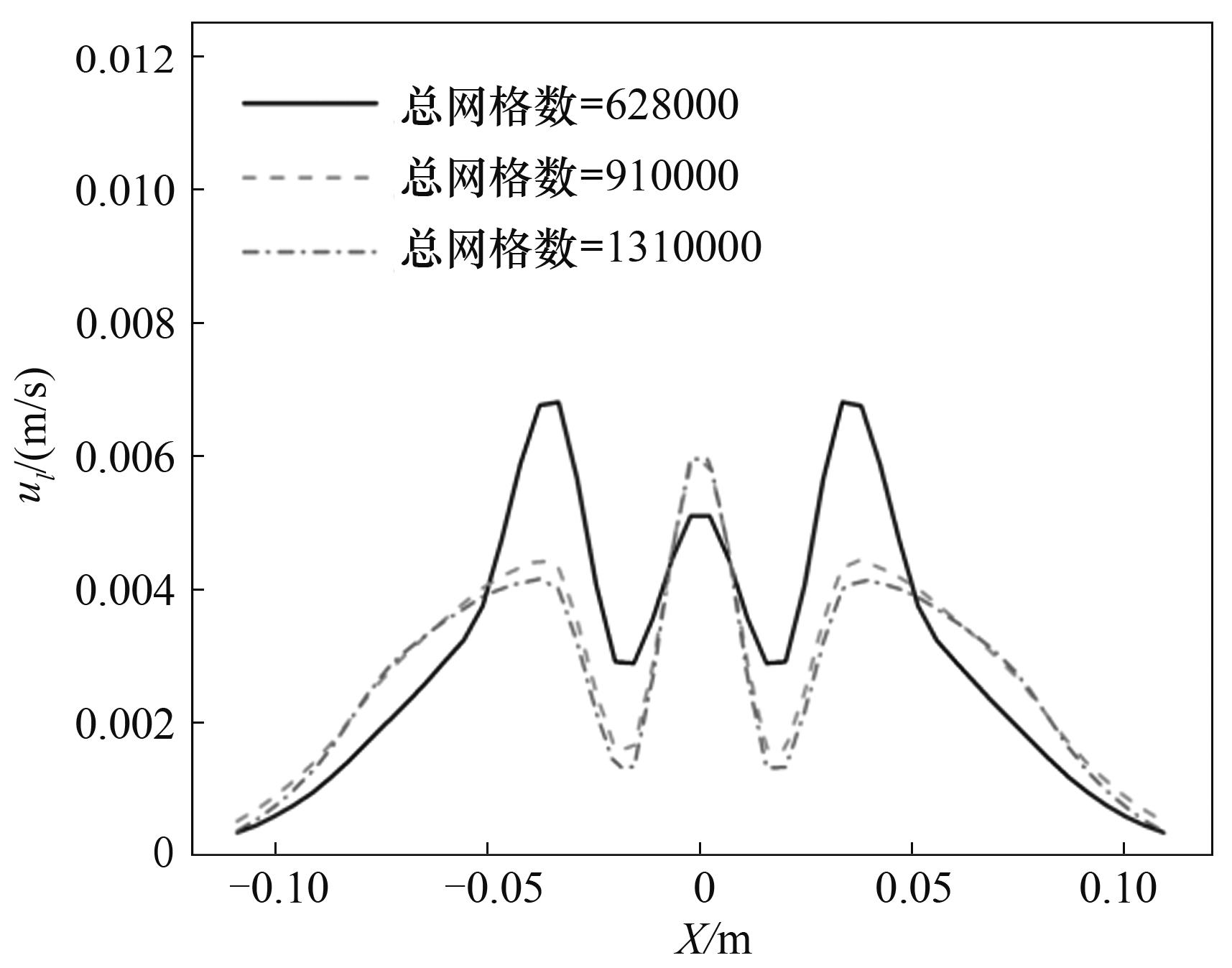

图5 Euler-PBE模型的网格无关性验证(新型分配器, φ1=30 mm, Ug=18 m3/h, Ul=0.1522 m3/h)

Fig.5 Mesh independence test on Euler-PBE model with experimental data (new G-L distributor, φ1=30 mm, Ug=18 m3/h, Ul=0.1522 m3/h)

图6 不同气液分配器(φ1=30 mm)在流动距离0.135 m处的液体速度分布云图

Fig.6 Contours of liquid velocity distribution at flow distance of 0.135 m of different types of G-L distributor (φ1=30 mm)

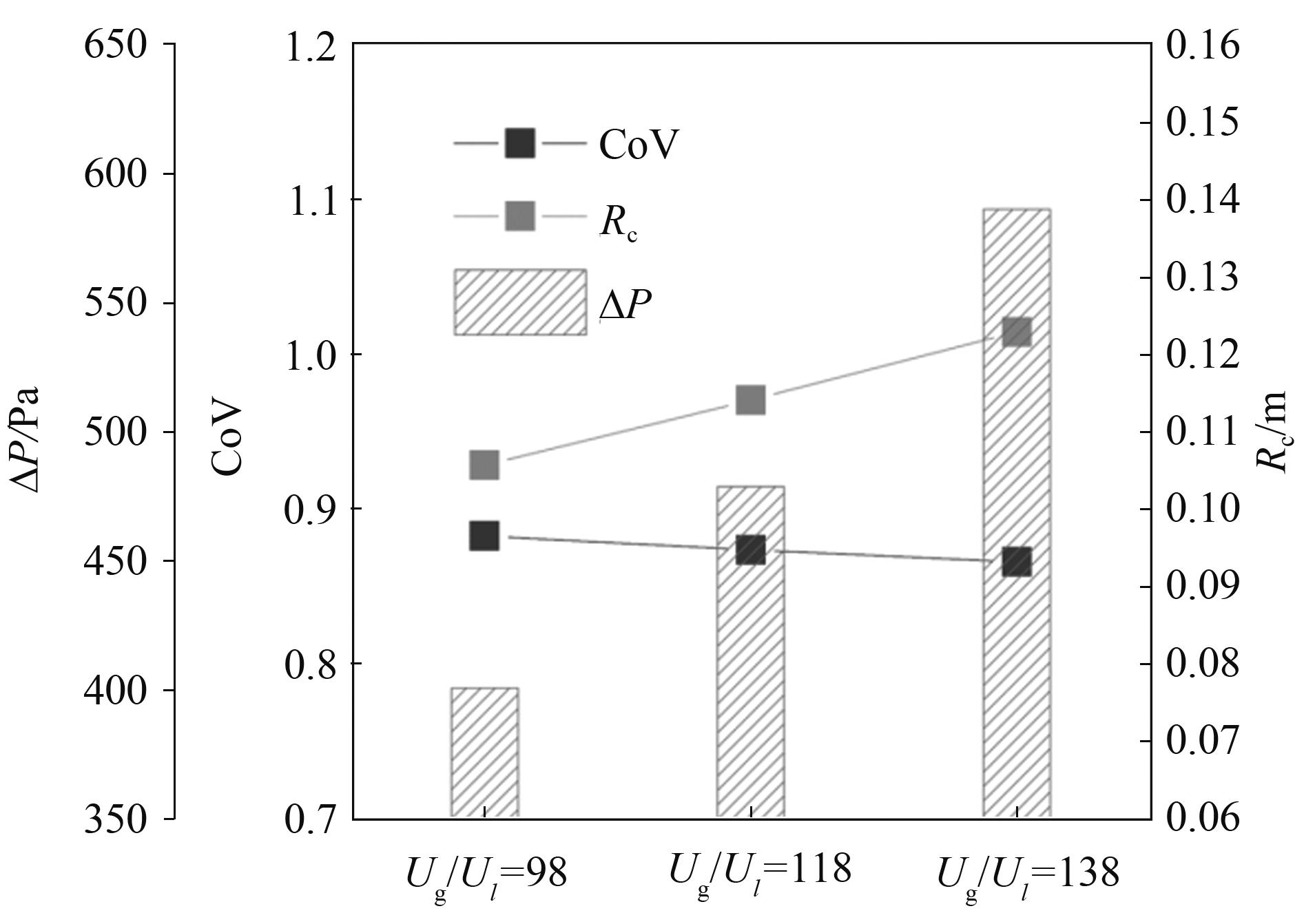

图8 不同气液比(Ug/Ul)下的压力降和流动距离0.135 m处的液相CoV和Rc (Ug=14.4 ~ 21.6 m3/h, Ul=0.1522 m3/h)

Fig.8 ?P, CoV and Rc under different Ug/Ul at flow distance of 0.135 m (Ug=14.4 ~ 21.6 m3/h, Ul=0.1522 m3/h)

| 实验序号 | φ2/mm | (h2+h3)/mm | α/(°) | ns | h5/mm | w | (h4-h6)/mm | Deg2/(°) | φ3/mm |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 50 | 21+29 | 7.5 | 4 | 13 | 2.5 | 9 | 15 | 23 |

| 2 | 50 | 21+29 | 7.5 | 6 | 16 | 3 | 17 | 45 | 31 |

| 3 | 50 | 21+29 | 7.5 | 8 | 19 | 3.5 | 13 | 30 | 27 |

| 4 | 50 | 28+29 | 15.12 | 4 | 16 | 3.5 | 9 | 30 | 31 |

| 5 | 50 | 28+29 | 15.12 | 6 | 19 | 2.5 | 17 | 15 | 27 |

| 6 | 50 | 28+29 | 15.12 | 8 | 13 | 3 | 13 | 45 | 23 |

| 7 | 50 | 35+29 | 10.12 | 4 | 19 | 3 | 9 | 45 | 27 |

| 8 | 50 | 35+29 | 10.12 | 6 | 13 | 3.5 | 17 | 30 | 23 |

| 9 | 50 | 35+29 | 10.12 | 8 | 16 | 2.5 | 13 | 15 | 31 |

| 10 | 53 | 21+29 | 15.12 | 4 | 19 | 3 | 17 | 30 | 23 |

| 11 | 53 | 21+29 | 15.12 | 6 | 13 | 3.5 | 13 | 15 | 31 |

| 12 | 53 | 21+29 | 15.12 | 8 | 16 | 2.5 | 9 | 45 | 27 |

| 13 | 53 | 28+29 | 10.12 | 4 | 13 | 2.5 | 17 | 45 | 31 |

| 14 | 53 | 28+29 | 10.12 | 6 | 16 | 3 | 13 | 30 | 27 |

| 15 | 53 | 28+29 | 10.12 | 8 | 19 | 3.5 | 9 | 15 | 23 |

| 16 | 53 | 35+29 | 7.5 | 4 | 16 | 3.5 | 17 | 15 | 27 |

| 17 | 53 | 35+29 | 7.5 | 6 | 19 | 2.5 | 13 | 45 | 23 |

| 18 | 53 | 35+29 | 7.5 | 8 | 13 | 3 | 9 | 30 | 31 |

| 19 | 56 | 21+29 | 10.12 | 4 | 16 | 3.5 | 13 | 45 | 23 |

| 20 | 56 | 21+29 | 10.12 | 6 | 19 | 2.5 | 9 | 30 | 31 |

| 21 | 56 | 21+29 | 10.12 | 8 | 13 | 3 | 17 | 15 | 27 |

| 22 | 56 | 28+29 | 7.5 | 4 | 19 | 3 | 13 | 15 | 31 |

| 23 | 56 | 28+29 | 7.5 | 6 | 13 | 3.5 | 9 | 45 | 27 |

| 24 | 56 | 28+29 | 7.5 | 8 | 16 | 2.5 | 17 | 30 | 23 |

| 25 | 56 | 35+29 | 15.12 | 4 | 13 | 2.5 | 13 | 30 | 27 |

| 26 | 56 | 35+29 | 15.12 | 6 | 16 | 3 | 9 | 15 | 23 |

| 27 | 56 | 35+29 | 15.12 | 8 | 19 | 3.5 | 17 | 45 | 31 |

表2 气液分配器模拟工况设计(L27(3,9))

Table 2 Orthogonal experiments of numerical simulation on G-L distributor(L27(3,9))

| 实验序号 | φ2/mm | (h2+h3)/mm | α/(°) | ns | h5/mm | w | (h4-h6)/mm | Deg2/(°) | φ3/mm |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 50 | 21+29 | 7.5 | 4 | 13 | 2.5 | 9 | 15 | 23 |

| 2 | 50 | 21+29 | 7.5 | 6 | 16 | 3 | 17 | 45 | 31 |

| 3 | 50 | 21+29 | 7.5 | 8 | 19 | 3.5 | 13 | 30 | 27 |

| 4 | 50 | 28+29 | 15.12 | 4 | 16 | 3.5 | 9 | 30 | 31 |

| 5 | 50 | 28+29 | 15.12 | 6 | 19 | 2.5 | 17 | 15 | 27 |

| 6 | 50 | 28+29 | 15.12 | 8 | 13 | 3 | 13 | 45 | 23 |

| 7 | 50 | 35+29 | 10.12 | 4 | 19 | 3 | 9 | 45 | 27 |

| 8 | 50 | 35+29 | 10.12 | 6 | 13 | 3.5 | 17 | 30 | 23 |

| 9 | 50 | 35+29 | 10.12 | 8 | 16 | 2.5 | 13 | 15 | 31 |

| 10 | 53 | 21+29 | 15.12 | 4 | 19 | 3 | 17 | 30 | 23 |

| 11 | 53 | 21+29 | 15.12 | 6 | 13 | 3.5 | 13 | 15 | 31 |

| 12 | 53 | 21+29 | 15.12 | 8 | 16 | 2.5 | 9 | 45 | 27 |

| 13 | 53 | 28+29 | 10.12 | 4 | 13 | 2.5 | 17 | 45 | 31 |

| 14 | 53 | 28+29 | 10.12 | 6 | 16 | 3 | 13 | 30 | 27 |

| 15 | 53 | 28+29 | 10.12 | 8 | 19 | 3.5 | 9 | 15 | 23 |

| 16 | 53 | 35+29 | 7.5 | 4 | 16 | 3.5 | 17 | 15 | 27 |

| 17 | 53 | 35+29 | 7.5 | 6 | 19 | 2.5 | 13 | 45 | 23 |

| 18 | 53 | 35+29 | 7.5 | 8 | 13 | 3 | 9 | 30 | 31 |

| 19 | 56 | 21+29 | 10.12 | 4 | 16 | 3.5 | 13 | 45 | 23 |

| 20 | 56 | 21+29 | 10.12 | 6 | 19 | 2.5 | 9 | 30 | 31 |

| 21 | 56 | 21+29 | 10.12 | 8 | 13 | 3 | 17 | 15 | 27 |

| 22 | 56 | 28+29 | 7.5 | 4 | 19 | 3 | 13 | 15 | 31 |

| 23 | 56 | 28+29 | 7.5 | 6 | 13 | 3.5 | 9 | 45 | 27 |

| 24 | 56 | 28+29 | 7.5 | 8 | 16 | 2.5 | 17 | 30 | 23 |

| 25 | 56 | 35+29 | 15.12 | 4 | 13 | 2.5 | 13 | 30 | 27 |

| 26 | 56 | 35+29 | 15.12 | 6 | 16 | 3 | 9 | 15 | 23 |

| 27 | 56 | 35+29 | 15.12 | 8 | 19 | 3.5 | 17 | 45 | 31 |

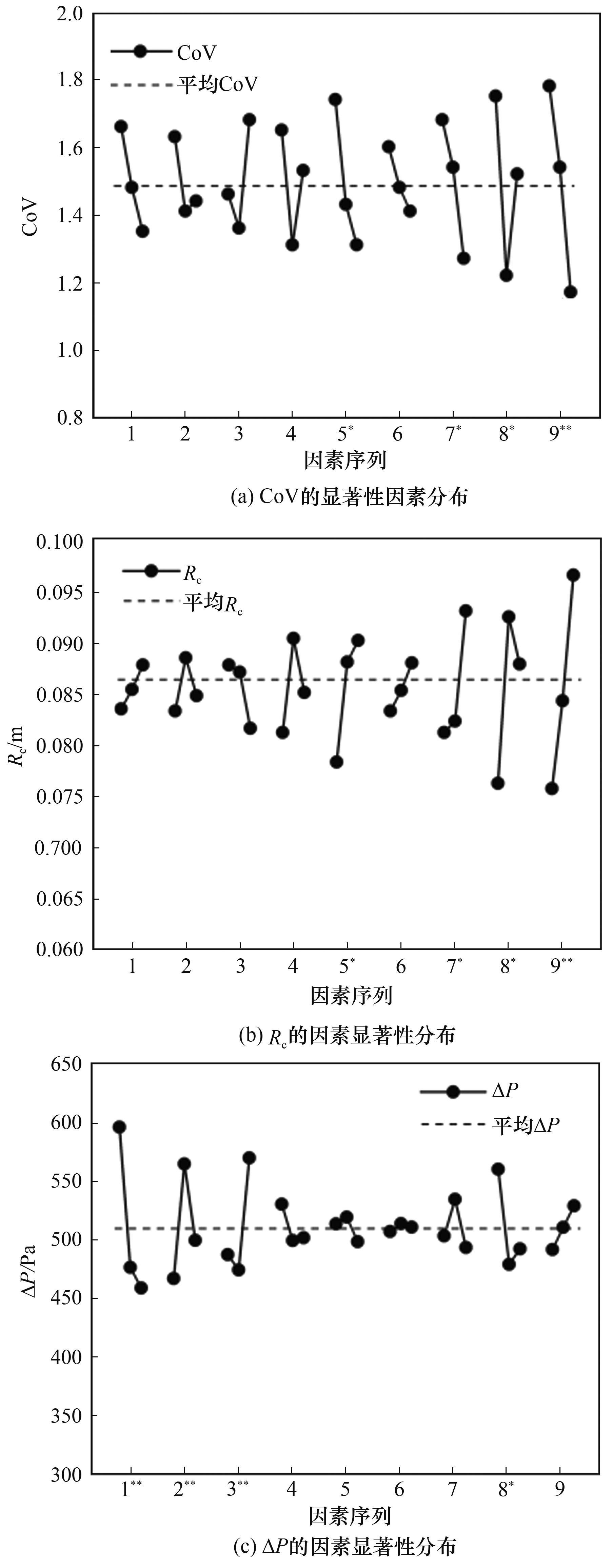

图13 CoV、Rc与压力降的因素显著性1—泡帽直径;2—降液管高;3—变径角度;4—条缝数量;5—条缝高度;6—条缝宽度;7—泡帽高度;8—扩孔角度;9—花板直径;*—显著(p < 0.05);**—非常显著(p < 0.01)

Fig.13 Main effect plots response for CoV, Rc, and ?P

| 1 | Singh B K, Jain E, Buwa V V. Feasibility of electrical resistance tomography for measurements of liquid holdup distribution in a trickle bed reactor[J]. Chemical Engineering Journal, 2019, 358: 564-579. |

| 2 | Dang-Vu T, Doan H D, Lohi A, et al. A new liquid distribution factor and local mass transfer coefficient in a random packed bed[J]. Chemical Engineering Journal, 2006, 123(3): 81-91. |

| 3 | Maiti R N, Nigam K D P. Gas–liquid distributors for trickle-bed reactors: a review[J]. Industrial & Engineering Chemistry Research, 2007, 46(19): 6164-6182. |

| 4 | Y.阿鲁恩, F.巴泽尔-巴希, F.奥吉耶, 等. 装有对水平度缺失很不敏感的分配元件的气液混合物的分配器盘: 103906563B[P]. 2016-12-28. |

| Yacine H, Frederic B B, Frederic A, et al. Distributor plate for gas/liquid mixture equipped with distributor elements largely insensitive to the lack of horizontality: 103906563B[P]. 2016-12-28. | |

| 5 | 孙凤侠, 刘俊涛, 刘国强. 滴流床反应组件: 205235933U[P]. 2016-05-18. |

| Sun F X, Liu J T, Liu G Q. Trickle bed reaction subassembly: 205235933U[P]. 2016-05-18. | |

| 6 | 周秋成, 张相平. 一种壳式气液混合器及一种壳式气液分配器: 208449276U[P]. 2019-02-01. |

| Zhou Q C, Zhang X P. Shell type gas -liquid mixer and shell type gas -liquid distributor: 208449276U[P]. 2019-02-01. | |

| 7 | 蔡连波. BL型气液分配器的试验研究[J]. 石油化工设备, 2009, 38(2): 1-4. |

| Cai L B. Experimental study on BL type vapor-liquid distributor[J]. Petro-Chemical Equipment, 2009, 38(2): 1-4. | |

| 8 | 佟博, 陈宇宁. 加氢反应器中气液分配器的发展与应用[J]. 当代化工研究, 2018(6): 111-112. |

| Tong B, Chen Y N. Development and application of gas-liquid distributor in hydrogenation reactor[J]. Modern Chemical Research, 2018(6): 111-112. | |

| 9 | 王岩, 彭德强, 李欣, 等. 新型气液分配器在加氢反应器的应用[J]. 当代化工, 2016, 45(9): 2147-2149. |

| Wang Y, Peng D Q, Li X, et al. Application of new gas-liquid distributor in hydrogenation reactors[J]. Contemporary Chemical Industry, 2016, 45(9): 2147-2149. | |

| 10 | 王少兵, 张占柱, 曾祥根, 等. 一种抽吸分流型气液分配器: 2757911Y[P]. 2006-02-15. |

| Wang S B, Zhang Z Z, Zeng X G, et al. Suction split flow type gas liquid distributor: 2757911Y[P]. 2006-02-15. | |

| 11 | 张兵, 李建明, 阮杰, 等. 滴流床反应装置气液分布器: 205042449U[P]. 2016-02-24. |

| Zhang B, Li J M, Ruan J, et al. Trickle bed reaction unit gas -liquid distributor: 205042449U[P]. 2016-02-24. | |

| 12 | Sie S T, Krishna R. Process development and scale up(III): Scale-up and scale-down of trickle bed processes[J]. Reviews in Chemical Engineering, 1998, 14(3): 203-252. |

| 13 | Al-Dahhan M H, Larachi F, Dudukovic M P, et al. High-pressure trickle-bed reactors: a review[J]. Industrial & Engineering Chemistry Research, 1997, 36(8): 3292-3314. |

| 14 | 王少兵, 张占柱, 毛俊义. 新型气液分配器的开发与应用[J]. 计算机与应用化学, 2016, 33(3): 287-291. |

| Wang S B, Zhang Z Z, Mao J Y. Development and application of the novel gas-liquid distributor[J]. Computers and Applied Chemistry, 2016, 33(3): 287-291. | |

| 15 | Marchot P, Toye D, Crine M, et al. Investigation of liquid maldistribution in packed columns by X-ray tomography[J]. Chemical Engineering Research and Design, 1999, 77(6): 511-518. |

| 16 | Sederman A J, Gladden L F. Magnetic resonance imaging as a quantitative probe of gas-liquid distribution and wetting efficiency in trickle-bed reactors[J]. Chemical Engineering Science, 2001, 56(8): 2615-2628. |

| 17 | Tyagi P, Buwa V V. Experimental characterization of dense gas-liquid flow in a bubble column using voidage probes[J]. Chemical Engineering Journal, 2017, 308: 912-928. |

| 18 | 侯亚飞, 李伟, 柳士开, 等. 加氢反应器气液分配器数值模拟与结构优化[J]. 石油炼制与化工, 2018, 49(5): 97-102. |

| Hou Y F, Li W, Liu S K, et al. Numerical simulation and structure optimization of distributor in hydrogenation reactor[J]. Petroleum Processing and Petrochemicals, 2018, 49(5): 97-102. | |

| 19 | 范勇, 荣蕾, 聂永广, 等. 加氢反应器气液分配盘数值模拟[J]. 化学反应工程与工艺, 2017, 33(4): 349-355. |

| Fan Y, Rong L, Nie Y G, et al. Numerical simulation of gas-liquid distribution plate in hydrogenation reactor[J]. Chemical Reaction Engineering and Technology, 2017, 33(4): 349-355. | |

| 20 | Jain E, Sau M, Buwa V V. Eulerian simulations of liquid distribution generated by chimney and bubble cap distributors[J]. Chemical Engineering Journal, 2021, 421: 127799. |

| 21 | Martínez M, Pallares J, López J, et al. Numerical simulation of the liquid distribution in a trickle-bed reactor[J]. Chemical Engineering Science, 2012, 76: 49-57. |

| 22 | Bazer-Bachi F, Haroun Y, Augier F, et al. Experimental evaluation of distributor technologies for trickle-bed reactors[J]. Industrial & Engineering Chemistry Research, 2013, 52(32): 11189-11197. |

| 23 | 雍玉梅, 杨超, 莫晗旸, 等. 一种降液管及抽吸型、溢流型、混合型气液分配器: 112546967A[P]. 2021-03-26. |

| Yong Y M, Yang C, Mo H Y, et al. Downcomer, suction type gas-liquid distributor, overflow type gas-liquid distributor and mixed type gas-liquid distributor: 112546967A[P]. 2021-03-26. | |

| 24 | Solomenko Z, Haroun Y, Fourati M, et al. Liquid spreading in trickle-bed reactors: experiments and numerical simulations using Eulerian-Eulerian two-fluid approach[J]. Chemical Engineering Science, 2015, 126: 698-710. |

| 25 | Zhang L, Gao G H, Sui H, et al. CFD simulation and experimental validation of fluid flow in pre-distributor[J]. Chinese Journal of Chemical Engineering, 2011, 19(5): 815-820. |

| 26 | Akbari V, Borhani T N G, Godini H R, et al. Model-based analysis of the impact of the distributor on the hydrodynamic performance of industrial polydisperse gas phase fluidized bed polymerization reactors[J]. Powder Technology, 2014, 267: 398-411. |

| 27 | Akbari V, Nejad Ghaffar Borhani T, Aramesh R, et al. Evaluation of hydrodynamic behavior of the perforated gas distributor of industrial gas phase polymerization reactor using CFD-PBM coupled model[J]. Computers & Chemical Engineering, 2015, 82: 344-361. |

| 28 | McGraw R. Description of aerosol dynamics by the quadrature method of moments[J]. Aerosol Science and Technology, 1997, 27(2): 255-265. |

| 29 | Lehr F, Millies M, Mewes D. Bubble-size distributions and flow fields in bubble columns[J]. AIChE Journal, 2002, 48(11): 2426-2443. |

| 30 | Hanusch F, Künzler M, Renner M, et al. Liquid distributor design for random packed columns[J]. Chemical Engineering Research and Design, 2019, 147: 689-698. |

| 31 | Moore F, Rukovena F. Liquid and gas distribution in commercial packed towers[J]. Chem. Plants & Processing, 1987, 8:11-15. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [5] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [6] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [9] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [10] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [11] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [12] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [15] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号