化工学报 ›› 2022, Vol. 73 ›› Issue (1): 175-183.DOI: 10.11949/0438-1157.20210929

收稿日期:2021-07-06

修回日期:2021-08-30

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

马友光

作者简介:陈一宇(1997—),男,硕士研究生,基金资助:

Yiyu CHEN( ),Chunying ZHU,Taotao FU,Youguang MA(

),Chunying ZHU,Taotao FU,Youguang MA( )

)

Received:2021-07-06

Revised:2021-08-30

Online:2022-01-05

Published:2022-01-18

Contact:

Youguang MA

摘要:

研究了具有三维交错菱形结构的微通道对离子液体1-丁基-3-甲基咪唑四氟硼酸盐([Bmim][BF4])水溶液吸收CO2过程的传质增强作用。实验主要聚焦于弹状流和破碎弹状流。考察了弹状流型下气液流量、离子液体浓度对体积传质系数kLa、增强因子E、CO2吸收率X及压力降ΔP的影响。结果表明,较之于直通道,三维菱形通道可以显著提高体积传质系数和CO2吸收率,其增强因子可达2.1,压力降仅增加 0.9 kPa。提出了一个新的体积传质系数kLa预测式,预测效果良好。采用VOF法模拟了微通道内气液两相流动过程,获得了连续相的速度矢量场。三维菱形通道能诱导涡流,强化传质过程。

中图分类号:

陈一宇, 朱春英, 付涛涛, 马友光. 三维菱形结构微通道内气液传质与强化[J]. 化工学报, 2022, 73(1): 175-183.

Yiyu CHEN, Chunying ZHU, Taotao FU, Youguang MA. Gas-liquid mass transfer and intensification in 3D-rhombus microchannel[J]. CIESC Journal, 2022, 73(1): 175-183.

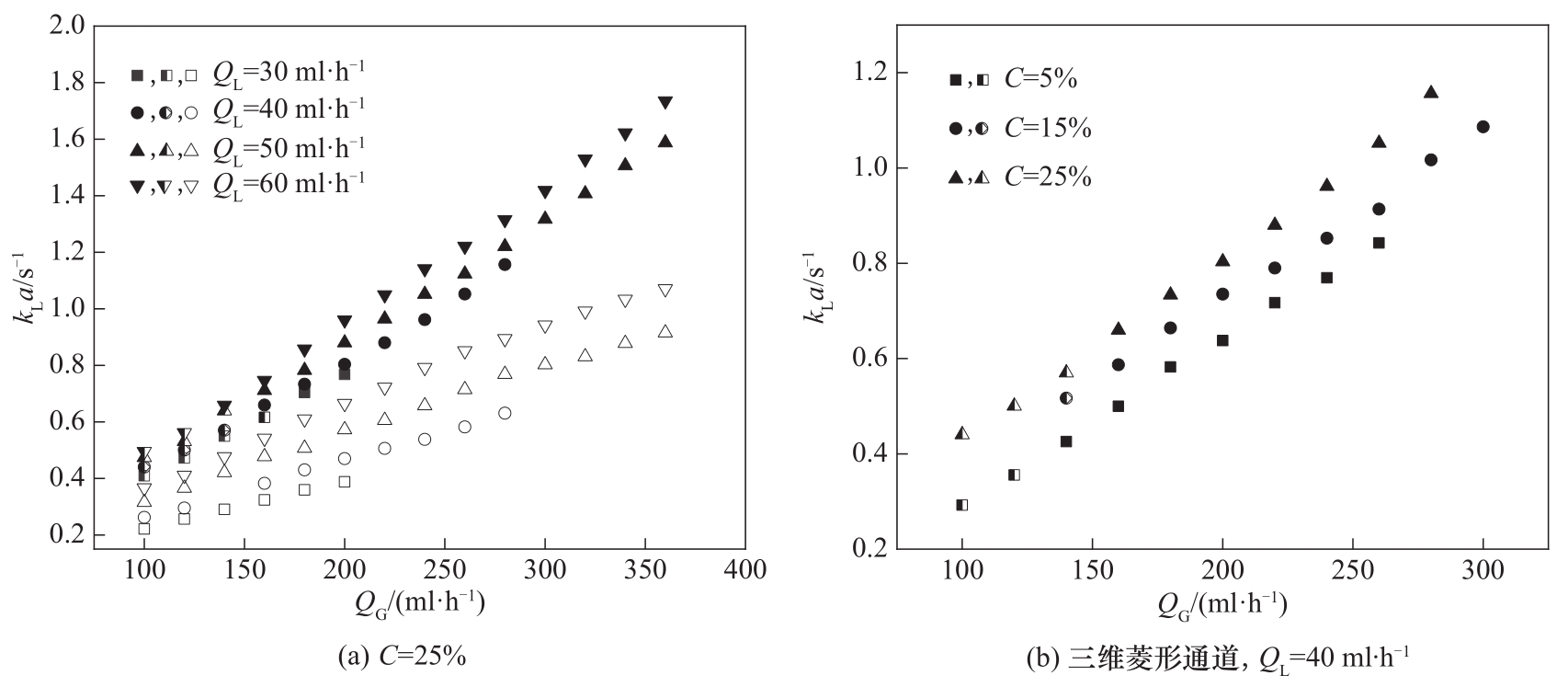

图6 气液流量和[Bmim][BF4]浓度对体积传质系数kLa的影响 [半实心符号(弹状流)和实心符号(破碎弹状流)为三维菱形通道数据,空心符号(弹状流)为直通道数据]

Fig.6 Effects of [Bmim][BF4] concentration and gas and liquid flow rates on volumetric mass transfer coefficient kLa

| 1 | Pang Z F, Jiang S K, Zhu C Y, et al. Mass transfer of chemical absorption of CO2 in a serpentine minichannel[J]. Chemical Engineering Journal, 2021, 414: 128791. |

| 2 | Ma D F, Zhu C Y, Fu T T, et al. Synergistic effect of functionalized ionic liquid and alkanolamines mixed solution on enhancing the mass transfer of CO2 absorption in microchannel[J]. Chemical Engineering Journal, 2021, 417: 129302. |

| 3 | 许宏图, 马宗燕, 王嘉明, 等. 铈锆固溶体担载的镍催化剂对CO2甲烷化性能研究[J]. 化学工业与工程, 2020, 37(6): 18-29. |

| Xu H T, Ma Z Y, Wang J M, et al. CO2 methanation performance of cerium zirconium solid solution supported nickel catalyst[J]. Chemical Industry and Engineering, 2020, 37(6): 18-29. | |

| 4 | Makarem M A, Farsi M, Rahimpour M R. CFD simulation of CO2 removal from hydrogen rich stream in a microchannel[J]. International Journal of Hydrogen Energy, 2021, 46(37): 19749-19757. |

| 5 | 王冠球, 林冠屹, 朱春英, 等. 微通道反应器的一维放大及气液传质特性[J]. 化工学报, 2021, 72(2): 937-944. |

| Wang G Q, Lin G Y, Zhu C Y, et al. One-dimensional amplification and gas-liquid mass transfer characteristics of microchannel reactor[J]. CIESC Journal, 2021, 72(2): 937-944. | |

| 6 | 王彦, 王靖涛. 微流控技术制备聚酰胺微胶囊的工艺研究[J]. 化学工业与工程, 2018, 35(6): 20-25. |

| Wang Y, Wang J T. Preparation of polyamide microcapsules based on microfluidics[J]. Chemical Industry and Engineering, 2018, 35(6): 20-25. | |

| 7 | Yue J, Boichot R, Luo L G, et al. Flow distribution and mass transfer in a parallel microchannel contactor integrated with constructal distributors[J]. AIChE Journal, 2010, 56(2): 298-317. |

| 8 | Sinton D. Energy: the microfluidic frontier[J]. Lab on a Chip, 2014, 14(17): 3127-3134. |

| 9 | Aravind G P, Deepu M. Numerical study on convective mass transfer enhancement by lateral sweep vortex generators[J]. International Journal of Heat and Mass Transfer, 2017, 115: 809-825. |

| 10 | Kaur J, Agarwal G P. Studies on protein transmission in thin channel flow module: the role of Dean vortices for improving mass transfer[J]. Journal of Membrane Science, 2002, 196(1): 1-11. |

| 11 | Mohand Kaci H, Habchi C, Lemenand T, et al. Flow structure and heat transfer induced by embedded vorticity[J]. International Journal of Heat and Mass Transfer, 2010, 53(17/18): 3575-3584. |

| 12 | Idrus-Saidi S A, Tang J B, Ghasemian M B, et al. Liquid metal core–shell structures functionalised via mechanical agitation: the example of Field’s metal[J]. Journal of Materials Chemistry A, 2019, 7(30): 17876-17887. |

| 13 | Su Y H, Chen G W, Zhao Y C, et al. Intensification of liquid-liquid two-phase mass transfer by gas agitation in a microchannel[J]. AIChE Journal, 2009, 55(8): 1948-1958. |

| 14 | Bengtsson M, Laurell T. Ultrasonic agitation in microchannels[J]. Analytical and Bioanalytical Chemistry, 2004, 378(7): 1716-1721. |

| 15 | Zhang F, Daghighi Y, Li D Q. Control of flow rate and concentration in microchannel branches by induced-charge electrokinetic flow[J]. Journal of Colloid and Interface Science, 2011, 364(2): 588-593. |

| 16 | Guan Y F, Yang T H, Wu J. Mixing and transport enhancement in microchannels by electrokinetic flows with charged surface heterogeneity[J]. Physics of Fluids, 2021, 33(4): 042006. |

| 17 | Burns J R, Ramshaw C. The intensification of rapid reactions in multiphase systems using slug flow in capillaries[J]. Lab on a Chip, 2001, 1(1): 10. |

| 18 | Wang J S, Li H, Li X G, et al. An intensification of mass transfer process for gas-liquid counter-current flow in a novel microchannel with limited path for CO2 capture[J]. Process Safety and Environmental Protection, 2021, 149: 905-914. |

| 19 | Adeosun J T, Lawal A. Mass transfer enhancement in microchannel reactors by reorientation of fluid interfaces and stretching[J]. Sensors and Actuators B: Chemical, 2005, 110(1): 101-111. |

| 20 | Fang W F, Yang J T. A novel microreactor with 3D rotating flow to boost fluid reaction and mixing of viscous fluids[J]. Sensors and Actuators B: Chemical, 2009, 140(2): 629-642. |

| 21 | Park J M, Kim D S, Kang T G, et al. Improved serpentine laminating micromixer with enhanced local advection[J]. Microfluidics and Nanofluidics, 2008, 4(6): 513-523. |

| 22 | Yang A S, Chuang F C, Chen C K, et al. A high-performance micromixer using three-dimensional Tesla structures for bio-applications[J]. Chemical Engineering Journal, 2015, 263: 444-451. |

| 23 | Liu R H, Stremler M A, Sharp K V, et al. Passive mixing in a three-dimensional serpentine microchannel[J]. Journal of Microelectromechanical Systems, 2000, 9(2): 190-197. |

| 24 | Yue J, Chen G W, Yuan Q, et al. Hydrodynamics and mass transfer characteristics in gas-liquid flow through a rectangular microchannel[J]. Chemical Engineering Science, 2007, 62(7): 2096-2108. |

| 25 | Zhu C Y, Lu Y T, Fu T T, et al. Experimental investigation on gas-liquid mass transfer with fast chemical reaction in microchannel[J]. International Journal of Heat and Mass Transfer, 2017, 114: 83-89. |

| 26 | Whitman W G. The two film theory of gas absorption[J]. International Journal of Heat and Mass Transfer, 1962, 5(5): 429-433. |

| 27 | 孙俊杰, 郝婷婷, 马学虎, 等. 壁面润湿性对微通道内二氧化碳-水两相流流动及传质性能的影响[J]. 化工学报, 2015, 66(9): 3405-3412. |

| Sun J J, Hao T T, Ma X H, et al. Surface wettability effect on carbon dioxide-water two-phase flow and mass transfer in rectangular microchannel[J]. CIESC Journal, 2015, 66(9): 3405-3412. | |

| 28 | Liu W W, Cheng L Y, Zhang Y M, et al. The physical properties of aqueous solution of room-temperature ionic liquids based on imidazolium: database and evaluation[J]. Journal of Molecular Liquids, 2008, 140(1/2/3): 68-72. |

| 29 | Ji X Y, Ma Y G, Fu T T, et al. Experimental investigation of the liquid volumetric mass transfer coefficient for upward gas-liquid two-phase flow in rectangular microchannels[J]. Brazilian Journal of Chemical Engineering, 2010, 27(4): 573-582. |

| 30 | Wu Y N, Fu T T, Zhu C Y, et al. Bubble coalescence at a microfluidic T-junction convergence: from colliding to squeezing[J]. Microfluidics and Nanofluidics, 2014, 16(1/2): 275-286. |

| 31 | Yin Y R, Zhu C Y, Fu T T, et al. Enhancement effect and mechanism of gas-liquid mass transfer by baffles embedded in the microchannel[J]. Chemical Engineering Science, 2019, 201: 264-273. |

| 32 | Zhang P, Yao C Q, Ma H Y, et al. Dynamic changes in gas-liquid mass transfer during Taylor flow in long serpentine square microchannels[J]. Chemical Engineering Science, 2018, 182: 17-27. |

| 33 | Akanksha, Pant K K, Srivastava V K. Mass transport correlation for CO2 absorption in aqueous monoethanolamine in a continuous film contactor[J]. Chemical Engineering and Processing: Process Intensification, 2008, 47(5): 920-928. |

| 34 | Ganapathy H, Shooshtari A, Dessiatoun S, et al. Fluid flow and mass transfer characteristics of enhanced CO2 capture in a minichannel reactor[J]. Applied Energy, 2014, 119: 43-56. |

| [1] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [5] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [6] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [7] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [8] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [9] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [10] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [11] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [12] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [13] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [14] | 王俐智, 杭钱程, 郑叶玲, 丁延, 陈家继, 叶青, 李进龙. 离子液体萃取剂萃取精馏分离丙酸甲酯+甲醇共沸物[J]. 化工学报, 2023, 74(9): 3731-3741. |

| [15] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号