化工学报 ›› 2020, Vol. 71 ›› Issue (9): 4303-4313.DOI: 10.11949/0438-1157.20200386

何忠义1( ),贾广跃1,2,张萌萌1,2,晏金灿2,3(

),贾广跃1,2,张萌萌1,2,晏金灿2,3( ),熊丽萍1,纪红兵2,4,5(

),熊丽萍1,纪红兵2,4,5( )

)

收稿日期:2020-04-13

修回日期:2020-06-24

出版日期:2020-09-05

发布日期:2020-09-05

通讯作者:

晏金灿,纪红兵

作者简介:何忠义(1971—),男,博士,教授,基金资助:

Zhongyi HE1( ),Guangyue JIA1,2,Mengmeng ZHANG1,2,Jincan YAN2,3(

),Guangyue JIA1,2,Mengmeng ZHANG1,2,Jincan YAN2,3( ),Liping XIONG1,Hongbing JI2,4,5(

),Liping XIONG1,Hongbing JI2,4,5( )

)

Received:2020-04-13

Revised:2020-06-24

Online:2020-09-05

Published:2020-09-05

Contact:

Jincan YAN,Hongbing JI

摘要:

制备了超声剥离的六方氮化硼负载油酸咪唑离子液体(OL-IL/h-BN)润滑添加剂,利用SEM、TEM、FTIR、TG及XRD等对其结构和形貌进行了表征。利用Zeta电位测试方法表征了其在聚乙二醇400中的分散性能,结果发现分散稳定性得到大幅提升。利用四球摩擦磨损试验机测试了摩擦学性能,结果显示减摩抗磨性能都优于h-BN。利用SEM和XPS对其磨斑表面形貌和成分进行了分析,XPS分析结果显示表面膜中含有化学吸附膜以及Fe2O3和B2O3等化学反应膜,这些膜的形成对减摩抗磨性能起到至关重要的作用。

中图分类号:

何忠义, 贾广跃, 张萌萌, 晏金灿, 熊丽萍, 纪红兵. 纳米六方氮化硼负载离子液体润滑添加剂的摩擦学特性[J]. 化工学报, 2020, 71(9): 4303-4313.

Zhongyi HE, Guangyue JIA, Mengmeng ZHANG, Jincan YAN, Liping XIONG, Hongbing JI. Tribological performance of hexagonal boron nitride supported ionic liquid lubricant additives[J]. CIESC Journal, 2020, 71(9): 4303-4313.

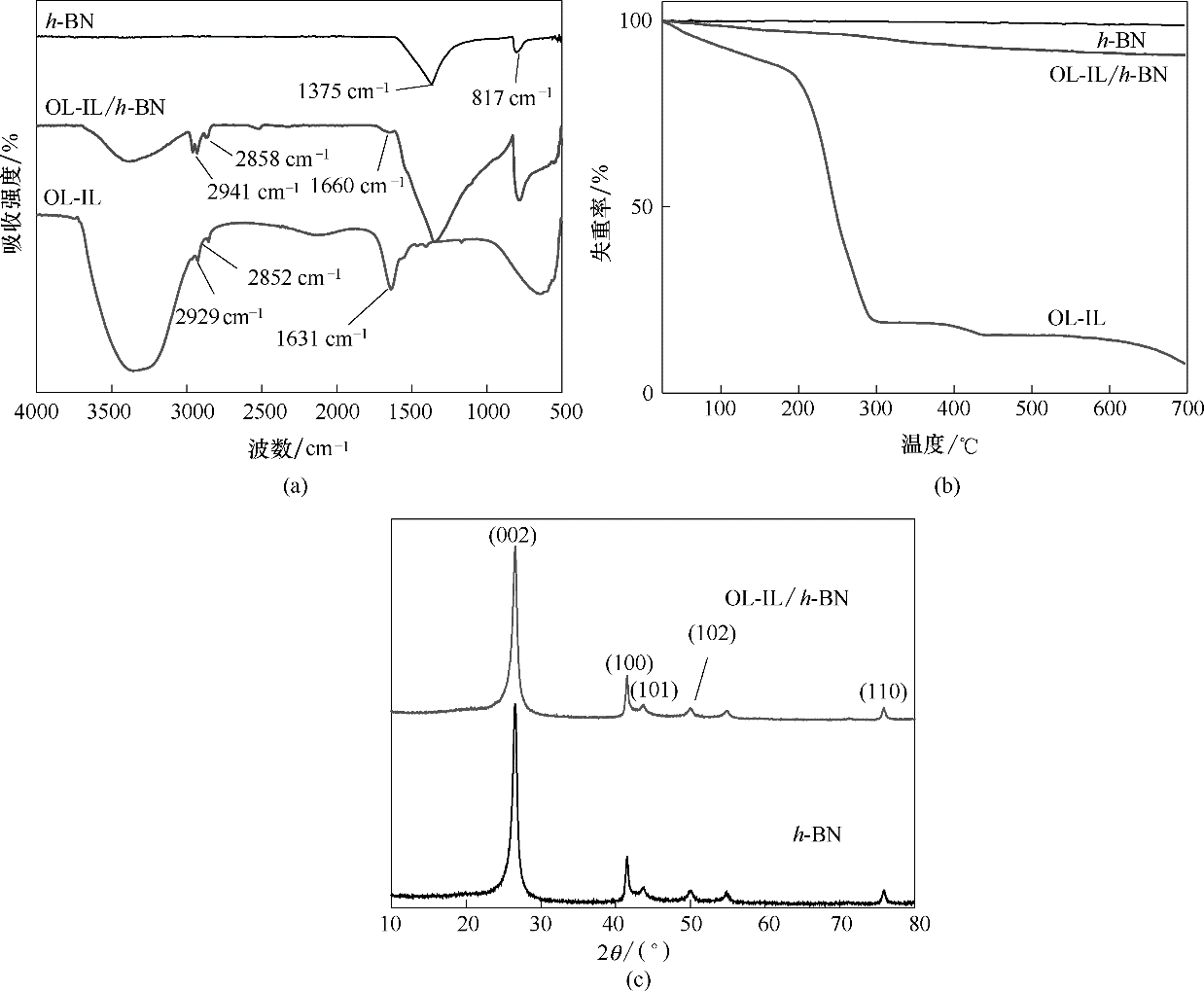

图5 h-BN、OL-IL、OL-IL/h-BN的红外谱图(a)、热重曲线(b)和h-BN、OL-IL/h-BN的XRD谱图(c)

Fig.5 FTIR spectra(a) and TG curves (b) of h-BN,OL-IL, OL-IL/h-BN; XRD patterns of h-BN, OL-IL/h-BN(c)

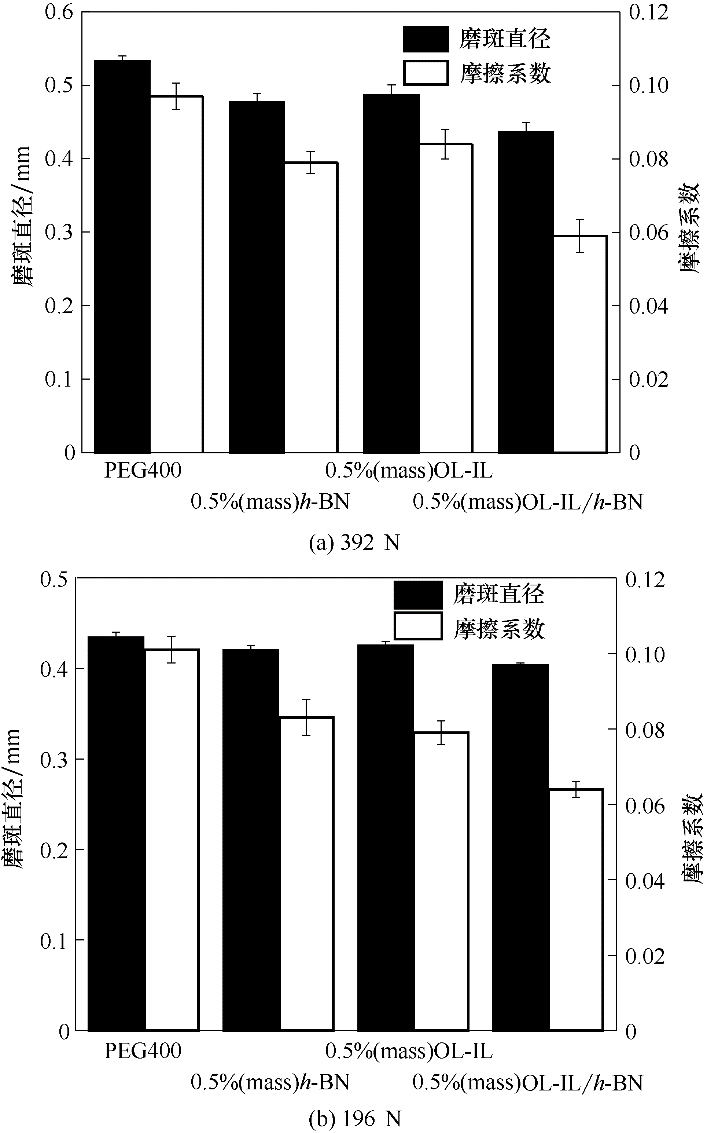

图7 不同载荷下,PEG400和0.5%(质量)h-BN、0.5%(质量)OL-IL、0.5%(质量) OL-IL/h-BN PEG400分散液的摩擦系数和磨斑直径(condition: 1200 r/min, 30 min, 30℃)

Fig.7 Friction coefficient and wear spot diameter of PEG400 and 0.5%(mass)h-BN, 0.5%(mass)OL-IL, 0.5%(mass) OL-IL/h-BN PEG400 dispersion under different loads

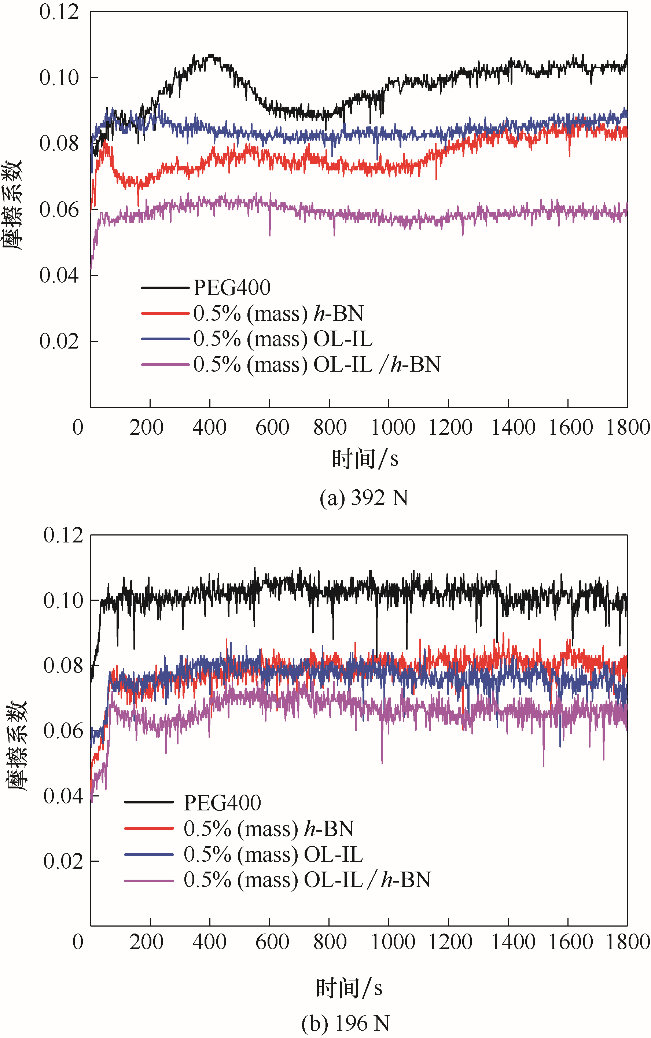

图8 不同载荷下,PEG400和0.5%(质量)h-BN、0.5%(质量)OL-IL、0.5%(质量) OL-IL/h-BN PEG400分散液的摩擦系数动态曲线(condition: 1200 r/min, 30 min, 30℃)

Fig.8 Friction coefficient curves of PEG400 and 0.5%(mass) h-BN hybrid, 0.5%(mass) OL-IL hybrid,0.5%(mass) OL-IL/h-BN PEG400 dispersion hybrid lubricated under different loads

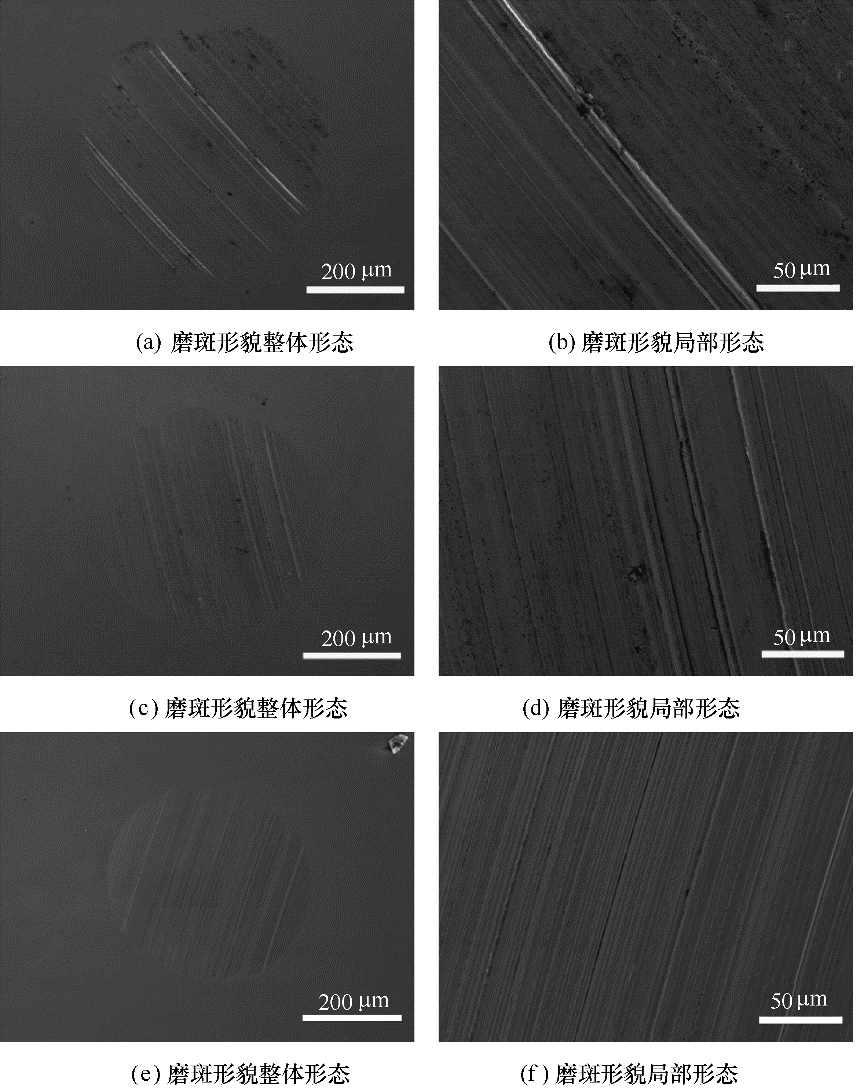

图9 加入PEG400(a)~(b)和0.5%(质量) h-BN(c)~(d)和0.5%(质量) OL-IL/h-BN (e)~(f)PEG400分散液的钢球磨痕表面SEM图(condition: 392 N, 1200 r/min, 30 min, 30℃)

Fig.9 SEM images of the wear scar on the balls lubricated with PEG400(a)—(b), 0.5%(mass) h-BN(c)—(d), 0.5%(mass) OL-IL/h-BN(e)—(f) PEG400 dispersion

图10 加入0.5%(质量) OL-IL/h-BNPEG400分散液的钢球磨痕表面XPS分析(condition: 392 N, 1200 r/min, 30 min)

Fig.10 XPS spectrum of C 1s(a),O 1s(b), Fe 2p(c), B 1s(d), N 1s(e)on the surface of the wear scar lubricated with 0.5%(mass) OL-IL/h-BN PEG400 dispersion

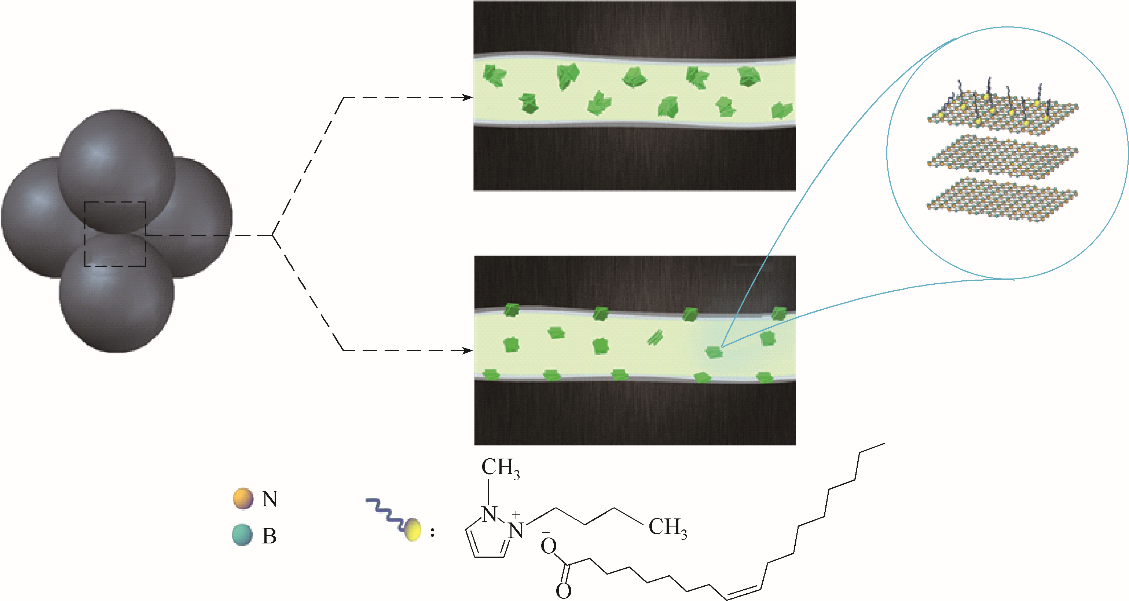

图11 0.5%(质量) h-BN与0.5%(质量) OL-IL/h-BN PEG400分散液中添加剂润滑示意图

Fig.11 Schematic diagram of the lubrication mechanism of water-based lubricant containing 0.5%(mass) h-BN and 0.5%(mass) OL-IL/h-BN PEG400 dispersion

| 1 | Zhou J F, Wu Z S, Zhang Z J, et al. Study on an antiwear and extreme pressure additive of surface coated LaF3 nanoparticles in liquid paraffin[J]. Wear, 2001, 249(5/6): 333-337. |

| 2 | Li Y G, Wang H L, Xie L M, et al. MoS2 nanoparticles grown on graphene: an advanced catalyst for the hydrogen evolution reaction[J]. Journal of the American Chemical Society, 2011, 133(19): 7296-7299. |

| 3 | Hwang H, Kim H, Cho J. MoS2 nanoplates consisting of disordered graphene-like layers for high rate lithium battery anode materials[J]. Nano Letters, 2011, 11(11): 4826-4830. |

| 4 | Diana B, Ali E, Anirud V S. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen[J]. Carbon, 2013, 59(8): 167-175. |

| 5 | Zhai W Z, Shi X L, Wang M, et al. Grain refinement: a mechanism for graphene nanoplatelets to reduce friction and wear of Ni3Al matrix self-lubricating composites[J]. Wear, 2014, 310(1/2): 33-40. |

| 6 | Njiwa P, Hadj-Aissa A, Afanasiev P, et al. Tribological properties of new MoS2 nanoparticles prepared by seed-assisted solution technique[J]. Tribology Letters, 2014, 55(3): 473-481. |

| 7 | E S F, Ye X Y, Zhu Z Z, et al. Tuning the structures of boron nitride nanosheets by template synthesis and their application as lubrication additives in water[J]. Applied Surface Science, 2019, 479: 119-127. |

| 8 | Pawlak Z, Pai R, Bayraktar E, et al. Lamellar lubrication in vivo and vitro: friction testing of hexagonal boron nitride[J]. Biosystems, 2008, 94(3): 202-208. |

| 9 | Singh D, Li L H, Chen Y, et al. High-efficient production of boron nitride nanosheets via an optimized ball milling process for lubrication in oil[J]. Scientific Reports, 2015, 4: 7288. |

| 10 | Jaiswal V, Kalkhanday K, Umrao S, et al. Synthesis, characterization, and tribological evaluation of TiO2-reinforced boron and nitrogen co-doped reduced graphene oxide based hybrid nanomaterials as efficient antiwear lubricant additives [J]. ACS Applied Materials & Interfaces, 2016, 8(18): 11698-11710. |

| 11 | Sato K, Horibe H, Shirai T, et al. Thermally conductive composite films of hexagonal boron nitride and polyimide with affinity-enhanced interfaces[J]. Journal of Materials Chemistry, 2010, 20(14): 2749-2752. |

| 12 | Perkin S. Ionic liquids in confined geometries[J]. Physical Chemistry Chemical Physics, 2012, 14(15): 5052-5062. |

| 13 | Battez A H, Gonzalez R, Viesca J L, et al. Tribological behaviour of two imidazolium ionic liquids as lubricant additives for steel/steel contacts[J]. Wear, 2009, 266(11/12): 1224-1228. |

| 14 | Qu J, Chi M, Meyer H M, et al. Nanostructure and composition of tribo-boundary films formed in ionic liquid lubrication[J]. Tribology Letters, 2011, 43(2): 205-211. |

| 15 | 刘维民,叶承峰,王海忠. 烷基咪唑四氟硼酸盐离子液作为润滑剂的摩擦学性能[J]. 摩擦学学报, 2001, 21(6): 482-484. |

| Liu W M, Ye C F, Wang H Z, et al. Tribological behavior of the ionic liquid of alkylimidazolium tetrafluoroborate as an additive[J]. Tribology, 2001, 21(6): 482-484. | |

| 16 | Guo Y X, Guo L H, Li G T, et al. Solvent-free ionic nanofluids based on graphene oxide-silica hybrid as high-performance lubricating additive[J]. Applied Surface Science, 2019, 471: 482-493. |

| 17 | Kobayashi M, Koide T, Hyon S H. Tribological characteristics of polyethylene glycol (PEG) as a lubricant for wear resistance of ultra-high-molecular-weight polyethylene (UHMWPE) in artificial knee join[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2014, 38: 33-38. |

| 18 | Wang B B, Hu E Z, Tu Z Q, et al. Characterization and tribological properties of rice husk carbon nanoparticles co-doped with sulfur and nitrogen[J]. Applied Surface Science, 2018, 462(31): 944-954. |

| 19 | Sen N, Singh K K, Mukhopadhyay S, et al. On continuous, solvent-free synthesis of ionic liquid [BMIM]Br in a microbore tube[J]. Journal of Radioanalytical & Nuclear Chemistry, 2016, 307(2): 1001-1009. |

| 20 | Kim T Y, Lee H W, Kim J E, et al. Synthesis of phase transferable graphene sheets using ionic liquid polymers[J]. ACS Nano, 2010, 4(3): 1612-1618. |

| 21 | Mo Y F, Wan Y F, Chau A, et al. Graphene/ionic liquid composite films and ion exchange[J]. Scientific Reports, 2014, 4: 5466. |

| 22 | Gusain R, Mungse H, Kumar N, et al. Covalently attached graphene-ionic liquid hybrid nanomaterials: synthesis, characterization and tribological application[J]. Jourmal of Materials Chemistry A, 2016, 4(3): 926-937. |

| 23 | Kumari S, Sharma O P, Gusain R, et al. Alkyl-chain-grafted hexagonal boron nitride nanoplatelets as oil-dispersible additives for friction and wear reduction[J]. ACS Applied Materials & Interfaces, 2015,7(6): 3708-3716. |

| 24 | 孙佳. 氮化硼负载杂多酸催化氧化燃油深度脱硫研究[D]. 镇江:江苏大学, 2017. |

| Sun J. Boron nitride supported heteropoly acid for catalytic oxidative deep desulfurization of fuels[D]. Zhenjiang: Jiangsu University, 2017. | |

| 25 | Fu L, Wang T, Yu J H, et al. An ultrathin high-performance heat spreader fabricated with hydroxylated boron nitride nanosheets[J]. 2D Materials, 2017, 4(2): 025047. |

| 26 | Zhu W S, Dai B L, Wu P W, et al. Graphene-Analogue hexagonal BN supported with tungsten-based ionic liquid for oxidative desulfurization of fuels[J]. ACS Sustainable Chemistry&Engineering, 2015, 3(1): 186-194. |

| 27 | Morishita T, Takahashi N. Highly thermally conductive and electrically insulating polymer nanocomposites with boron nitride nanosheet/ionic liquid complexes[J]. RSC Advances, 2017, 7(58): 36450-36459. |

| 28 | Wang L X, Han W F, Ge C H, et al. Covalent functionalized boron nitride nanosheets as efficient lubricant oil additives[J]. Advanced Materials Interfaces, 2019, 6(21): 1901172. |

| 29 | Mahyari M, Shaabani A, Bide Y. Gold nanoparticles supported on supramolecular ionic liquid grafted graphene: a bifunctional catalyst for the selective aerobic oxidation of alcohols[J]. RSC Advances, 2013, 3(44): 22509-22517. |

| 30 | Wu L Y, Wu K, Lei C X, et al. Surface modifications of boron nitride nanosheets for poly(vinylidene fluoride) based film capacitor: artful virtue of edge-hydroxylation[J]. Journal of Materials Chemistry A, 2019, 7(13):7664-7674. |

| 31 | Xiao F, Naficy S, Casillas G, et al. Edge-hydroxylated boron nitride nanosheets as an effective additive to improve the thermal response of hydrogels[J]. Advanced Materials, 2015, 27(44): 7247-7247. |

| 32 | Zhang H N, Pan J J, He X C, et al. Zeta potential of nafion molecules in isopropanol-water mixture solvent[J]. Journal of Applied Polymer Science, 2008, 107(5): 3306-3309. |

| 33 | Khoo K S, Teh E J, Leong Y K, et al. Hydrogen bonding and interparticle forces in platelet α-Al2O3 dispersions: yield stress and zeta potential[J]. Langmuir, 2009, 25(6):3418-3424. |

| 34 | Zheng Z Y, Cox M, Li B. Surface modification of hexagonal boron nitride nanomaterials: a review[J]. Journal of Materials Science, 2018, 53(1): 66-99. |

| 35 | 于鹤龙, 徐滨士, 许一, 等. 纳米铜添加剂改善钢-铝摩擦副摩擦磨损性能的研究[J]. 摩擦学学报, 2006, 26(5): 433-438. |

| Yu H L, Xu B S, Xu Y, et al. Friction and sliding-wear behavior of steel-aluminum tribopair improved by nanocopper additive[J]. Tribology, 2006, 26(5): 433-438. | |

| 36 | Bas H, Karabacak Y E. Investigation of the effects of boron additives on the performance of engine oil[J]. Tribology Transactions, 2014, 57(4): 740-748. |

| 37 | Wu H X, Qin L G, Zeng Q F, et al. Understanding the physical adsorption action mechanism of MoS2,nanoparticles in boundary lubrication with different polyisobutyleneamine succinimide(PIBS) concentrations[J]. Tribology Letters, 2015, 60(2): 26. |

| 38 | Song W, Yan J C, Ji H B. Fabrication of GNS/MoS2 composite with different morphology and its tribological performance as a lubricant additive[J]. Applied Surface Science, 2019, 469: 226-235. |

| 39 | Lee K, Hwang Y, Cheong S, et al. Understanding the role of nanoparticles in nano-oil lubrication[J]. Tribology Letters, 2009, 35(2): 127-131. |

| 40 | Alazemi A, Etacheri V, Dysart A D, et al. Ultrasmooth submicrometer carbon spheres as lubricant additives for friction and wear reduction[J]. ACS Applied Materials & Interfaces, 2015, 7(9): 5514-5521. |

| 41 | Ma S Y, Zheng S H, Cao D X, et al. Anti-wear and friction performance of ZrO2 nanoparticles as lubricant additive[J]. Particuology, 2010, 8(5):468-472. |

| 42 | He J Q, Sun J L, Meng Y N, et al. Preliminary investigations on the tribological performance of hexagonal boron nitride nanofluids as lubricant for steel/steel friction pairs[J]. Surface Topography Metrology & Properties, 2019, 7(1): 015022. |

| 43 | Song W, Yan J C, Ji H B. Tribological study of SOCNTs@MoS2 composite as a lubricant additive: synergistic effect[J]. Industrial & Engineering Chemistry Research, 2018, 57(20): 6878-6887. |

| [1] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [2] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [3] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [4] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [5] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [6] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [7] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [8] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [9] | 王俐智, 杭钱程, 郑叶玲, 丁延, 陈家继, 叶青, 李进龙. 离子液体萃取剂萃取精馏分离丙酸甲酯+甲醇共沸物[J]. 化工学报, 2023, 74(9): 3731-3741. |

| [10] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [11] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [12] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [13] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [14] | 盛冰纯, 于建国, 林森. 铝基锂吸附剂分离高钠型地下卤水锂资源过程研究[J]. 化工学报, 2023, 74(8): 3375-3385. |

| [15] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号