化工学报 ›› 2021, Vol. 72 ›› Issue (12): 6351-6360.DOI: 10.11949/0438-1157.20211181

叶珍珍1( ),陈鑫祺1,汪剑1,李博凡1,崔超婕1(

),陈鑫祺1,汪剑1,李博凡1,崔超婕1( ),张刚2,钱陆明2,金鹰1,2,骞伟中1(

),张刚2,钱陆明2,金鹰1,2,骞伟中1( )

)

收稿日期:2021-08-17

修回日期:2021-10-09

出版日期:2021-12-05

发布日期:2021-12-22

通讯作者:

崔超婕,骞伟中

作者简介:叶珍珍(1990—),女,研究助理,基金资助:

Zhenzhen YE1( ),Xinqi CHEN1,Jian WANG1,Bofan LI1,Chaojie CUI1(

),Xinqi CHEN1,Jian WANG1,Bofan LI1,Chaojie CUI1( ),Gang ZHANG2,Luming QIAN2,Ying JIN1,2,Weizhong QIAN1(

),Gang ZHANG2,Luming QIAN2,Ying JIN1,2,Weizhong QIAN1( )

)

Received:2021-08-17

Revised:2021-10-09

Online:2021-12-05

Published:2021-12-22

Contact:

Chaojie CUI,Weizhong QIAN

摘要:

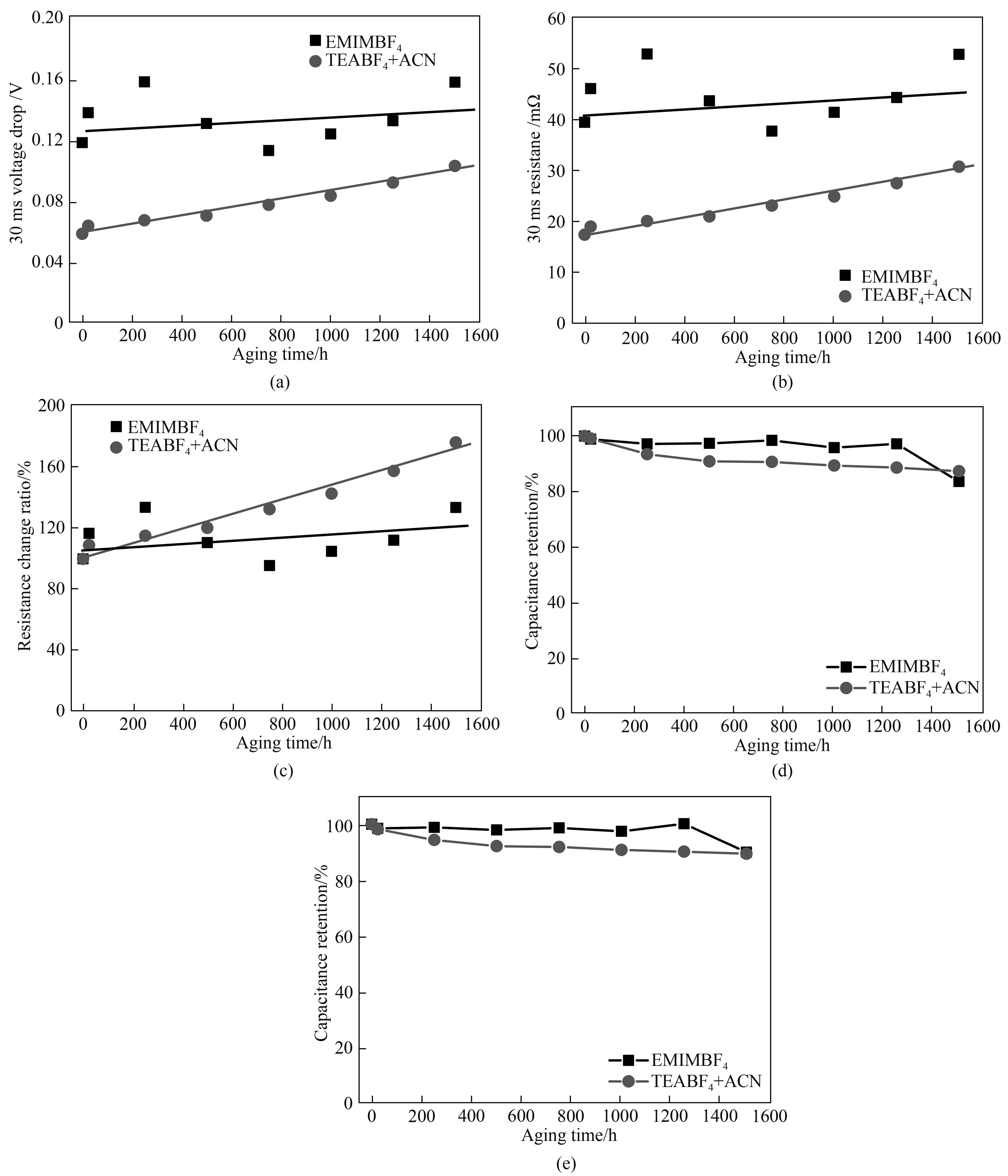

构筑了介孔炭,离子液体(EMIMBF4)与泡沫铝极片结构的超级电容器软包(容量为40 F),评测了其在2.7 V,65℃,1500 h老化实验中的性能。利用恒流充放电、恒流-恒压充放电模式评测,该电容器经过连续1500 h的高温处理后电容值衰减约10%,内阻增加比例低于40%。与传统的乙腈基电解液软包对比,虽然乙腈基软包起始内阻低,但产气多,且高温循环条件下容量衰减比例和内阻增加比例均劣于离子液体基电解液。上述对比说明,离子液体基电解液在泡沫铝三维导电导热结构的配合下,具有了良好的长周期循环性能。同时,由于其无毒性,可以用于封闭的楼宇空间或其他场所,提供本质安全性。

中图分类号:

叶珍珍, 陈鑫祺, 汪剑, 李博凡, 崔超婕, 张刚, 钱陆明, 金鹰, 骞伟中. 离子液体型超级电容器软包高温老化性能评测研究[J]. 化工学报, 2021, 72(12): 6351-6360.

Zhenzhen YE, Xinqi CHEN, Jian WANG, Bofan LI, Chaojie CUI, Gang ZHANG, Luming QIAN, Ying JIN, Weizhong QIAN. Evaluation of aging performance under high temperature of ionic liquid-based pouch supercapacitor[J]. CIESC Journal, 2021, 72(12): 6351-6360.

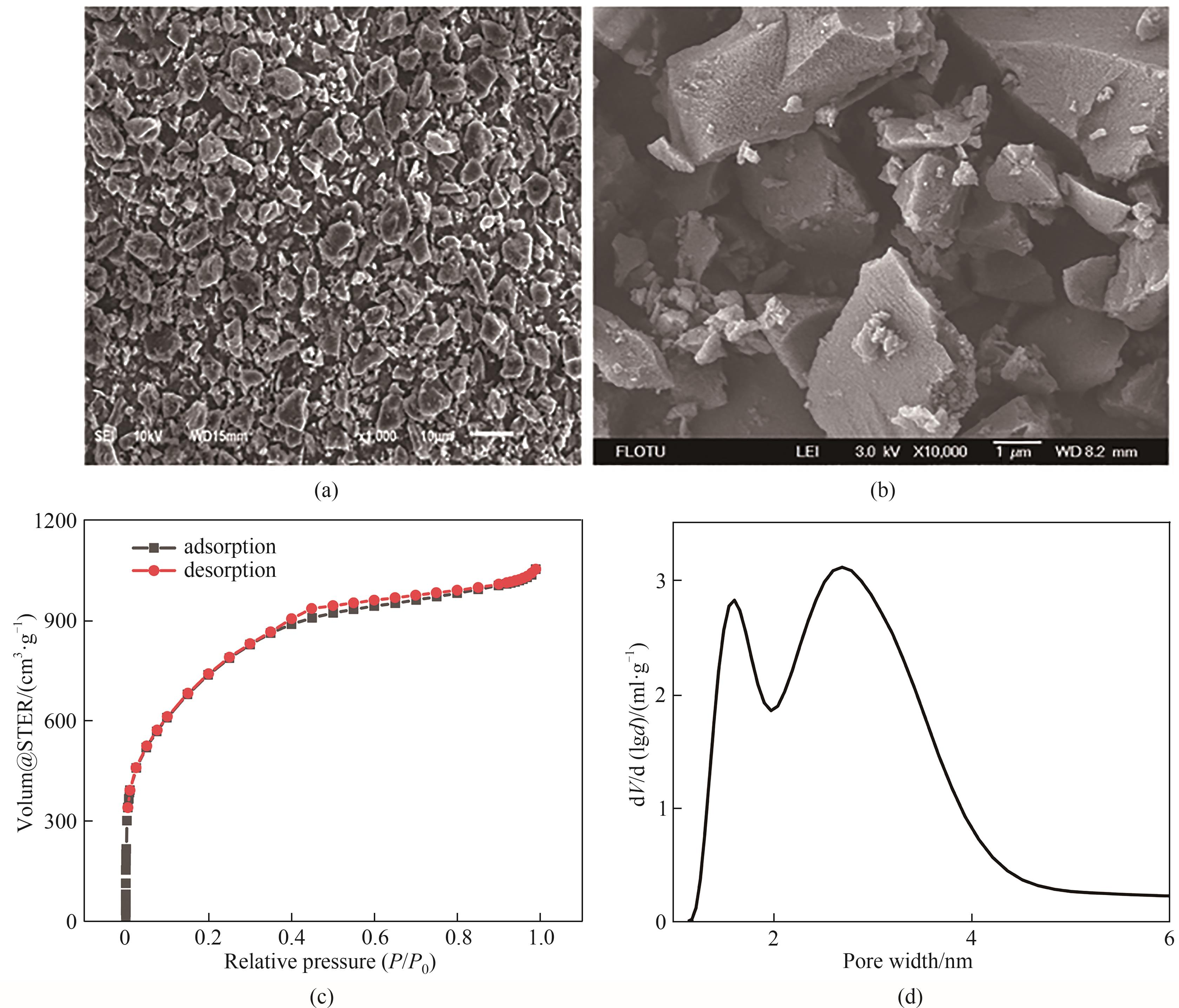

图1 介孔炭的基本特性表征。(a)和(b)为材料的低倍和高倍扫描电镜照片;(c)和(d)为材料的氮气吸脱附曲线和孔径分布

Fig.1 Basic characterization of mesoporous carbon. Low (a) and high (b) magnification SEM images of the material; Nitrogen absorption and desorption curves (c) and pore size distribution (d) of the material

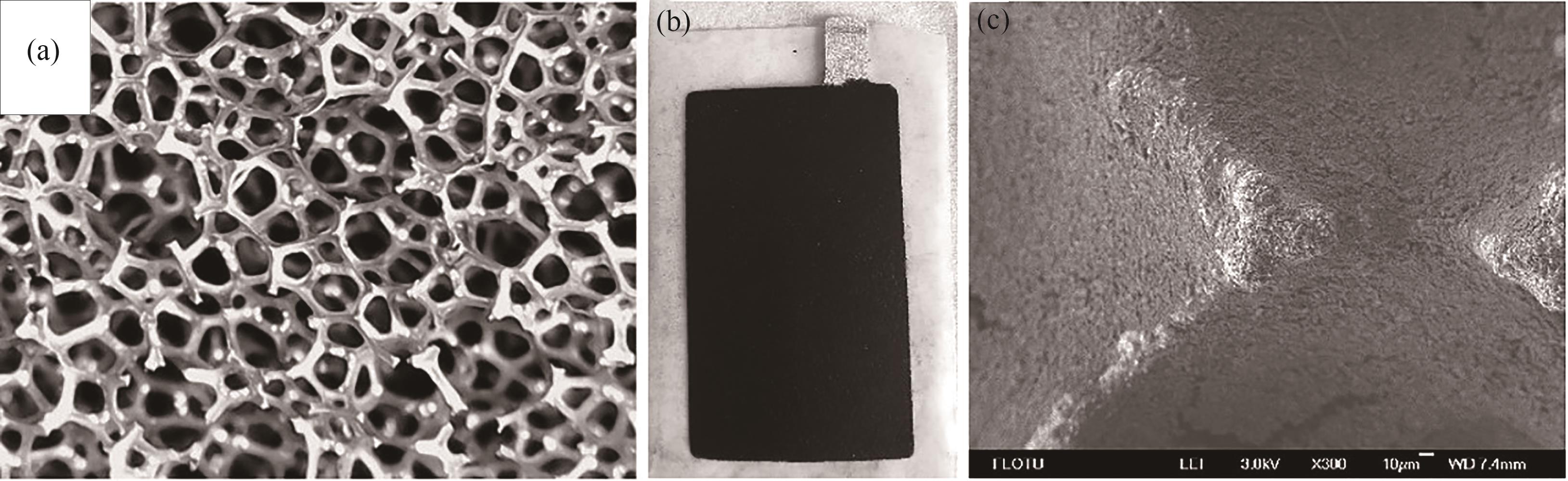

图2 三维通孔泡沫铝集流体的光学照片(a);介孔炭与泡沫铝集流体构建的复合极片(b);介孔炭颗粒在泡沫铝突起表面的附着情况(c)

Fig.2 Optical photograph of 3D through-hole aluminum foam current collector (a); Mesoporous carbon and aluminum foam composite electrode (b); Adhesion of mesoporous carbon particles on the protuberant surface of aluminum foam (c)

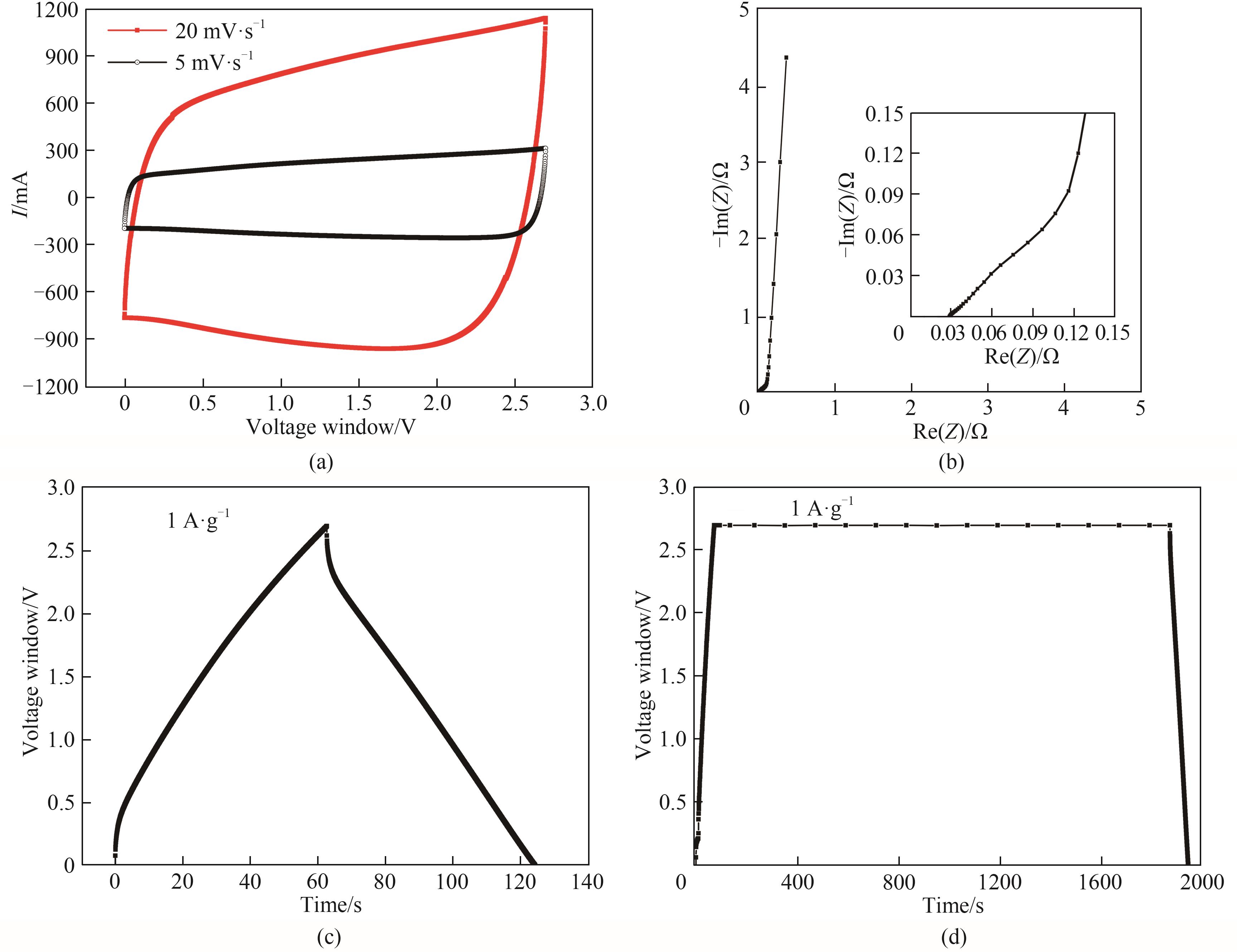

图3 介孔炭-EMIMBF4-泡沫铝体系的基本电化学测试。(a)循环伏安曲线;(b)电化学阻抗谱图;(c)恒流充放电曲线和(d)恒流-恒压充放电曲线

Fig.3 Basic electrochemical tests of mesoporous carbon-EMIMBF4-Al foam system. CV curves (a); EIS spectra (b); Constant current charge-discharge curve (c) and constant current-constant voltage charge-discharge curve (d)

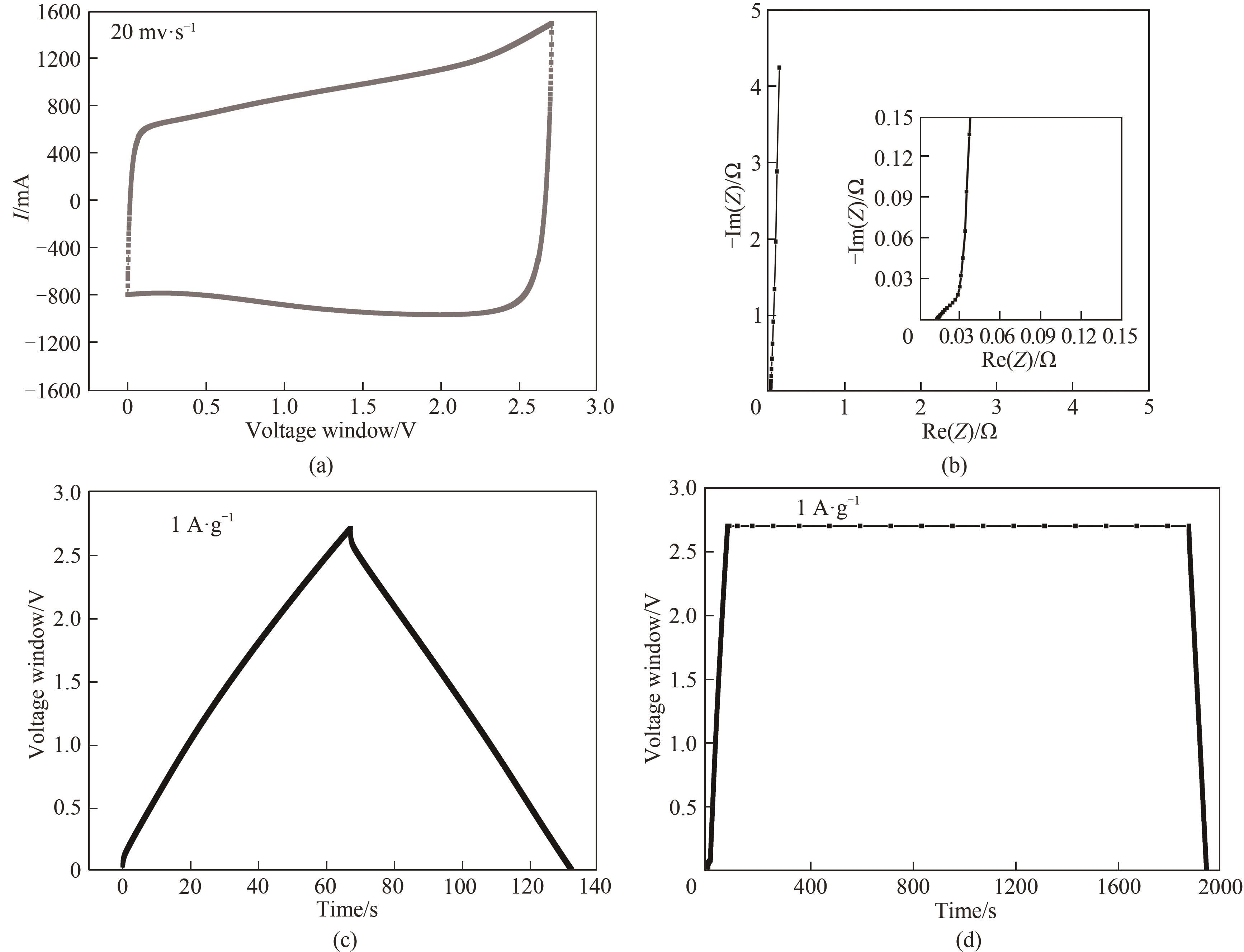

图4 介孔炭-TEABF4/ACN-泡沫铝体系的基本电化学测试。(a)循环伏安曲线;(b)电化学阻抗谱图;(c)恒流充放电曲线和(d)恒流-恒压充放电曲线

Fig.4 Basic electrochemical tests of mesoporous carbon-TEABF4/ACN-Al foam system. CV curve (a); EIS spectra (b); Constant current charge-discharge curve (c) and constant current - constant voltage charge-discharge curve (d)

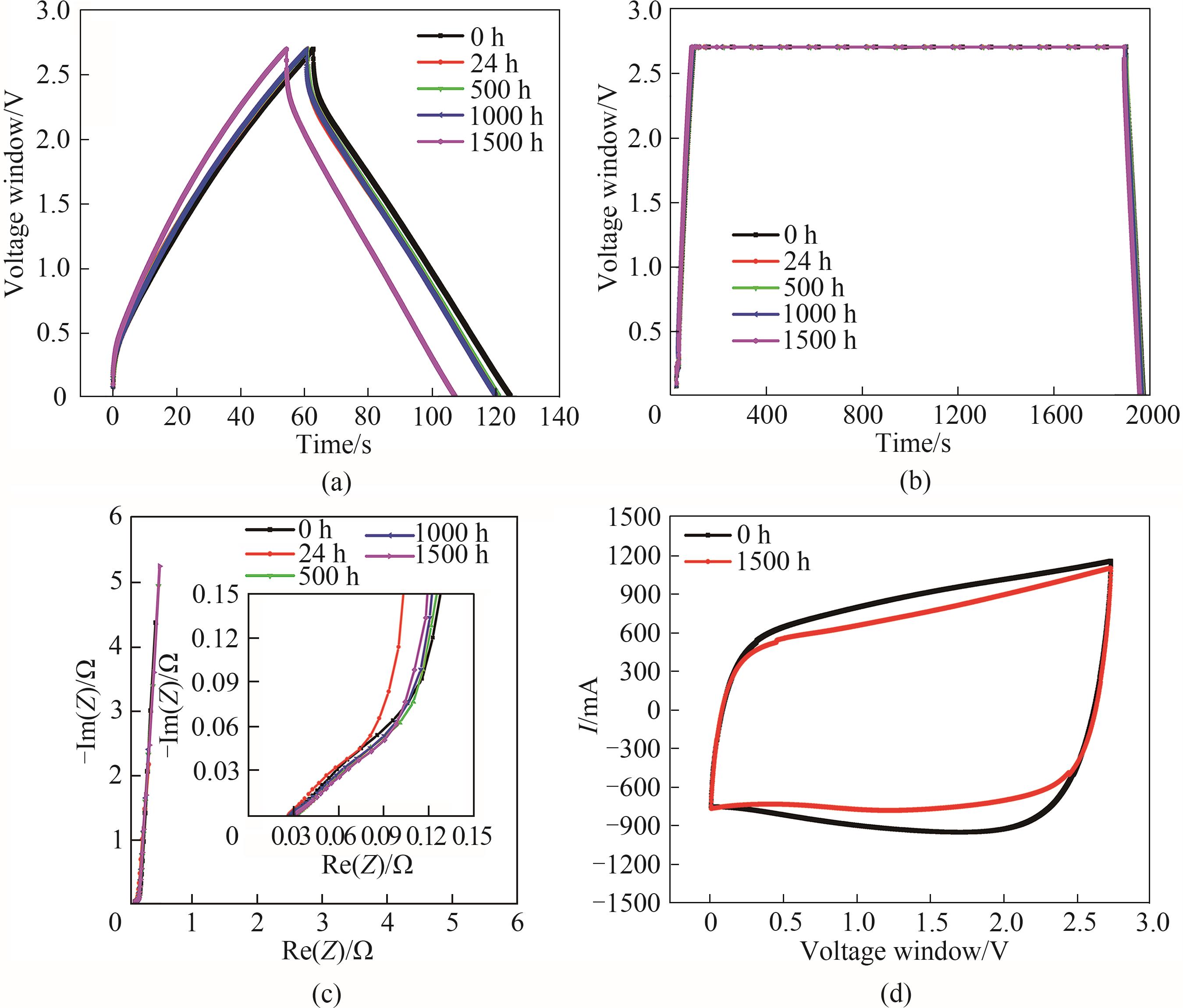

图5 介孔炭-EMIMBF4-泡沫铝体系的高温长时间测试。(a)恒流充放电曲线和(b)恒流-恒压充放电曲线;(c)电化学阻抗谱图;(d)循环伏安曲线

Fig.5 Long cycling test of mesoporous carbon-EMIMBF4-Al foam system at high temperature. Constant current charge-discharge curves (a) and constant current-constant voltage charge-discharge curves (b); EIS spectra (c); CV curves (d)

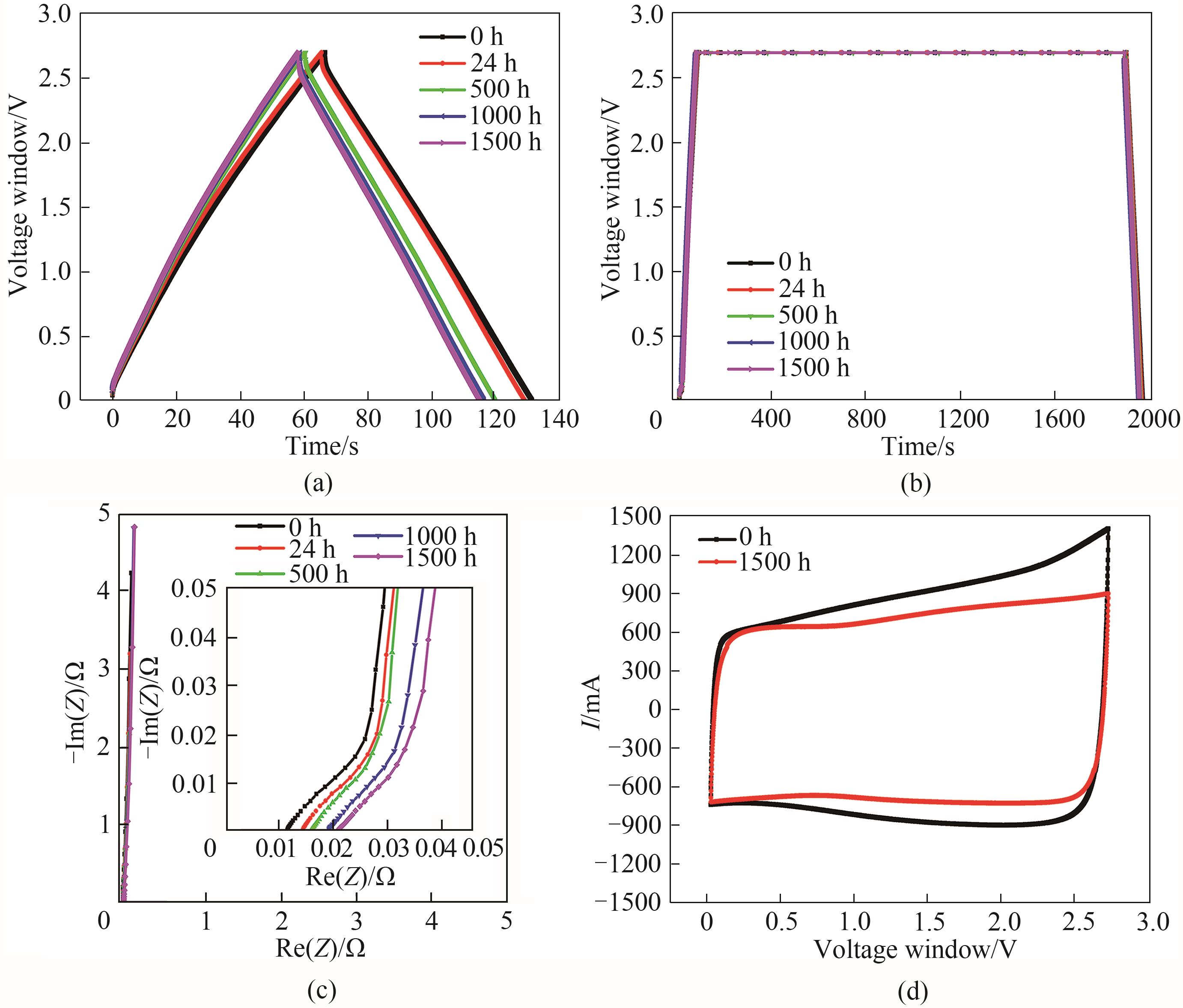

图6 介孔炭-TEABF4/ACN-泡沫铝体系的高温长时间测试。(a)恒流充放电曲线和(b)恒流-恒压充放电曲线;(c)电化学阻抗谱图;(d)循环伏安曲线

Fig.6 Long cycling test of mesoporous carbon-TEABF4/ACN-Al foam system at high temperature. Constant current charge-discharge curves (a) and constant current-constant voltage charge-discharge curves (b); EIS spectra (c); CV curves (d)

图7 EMIBF4 和TEABF4/ACN两体系的高温老化数据对比。(a)器件30 ms电压降值比较;(b)器件30 ms电阻值和(c)归一化比较;(d)恒流充放电比容量和(e)恒流-恒压充放电比容量进行归一化比较

Fig.7 Comparison of high temperature aging performance between EMIMBF4 and TEABF4/ACN systems. Comparison of 30 ms voltage drop of devices (a); Comparison of 30 ms resistance values (b) and ratio of resistance change (c); Comparison of the ratio of the specific capacitance change by the constant current charge-discharge mode (d) and the constant current-constant voltage charge-discharge mode (e)

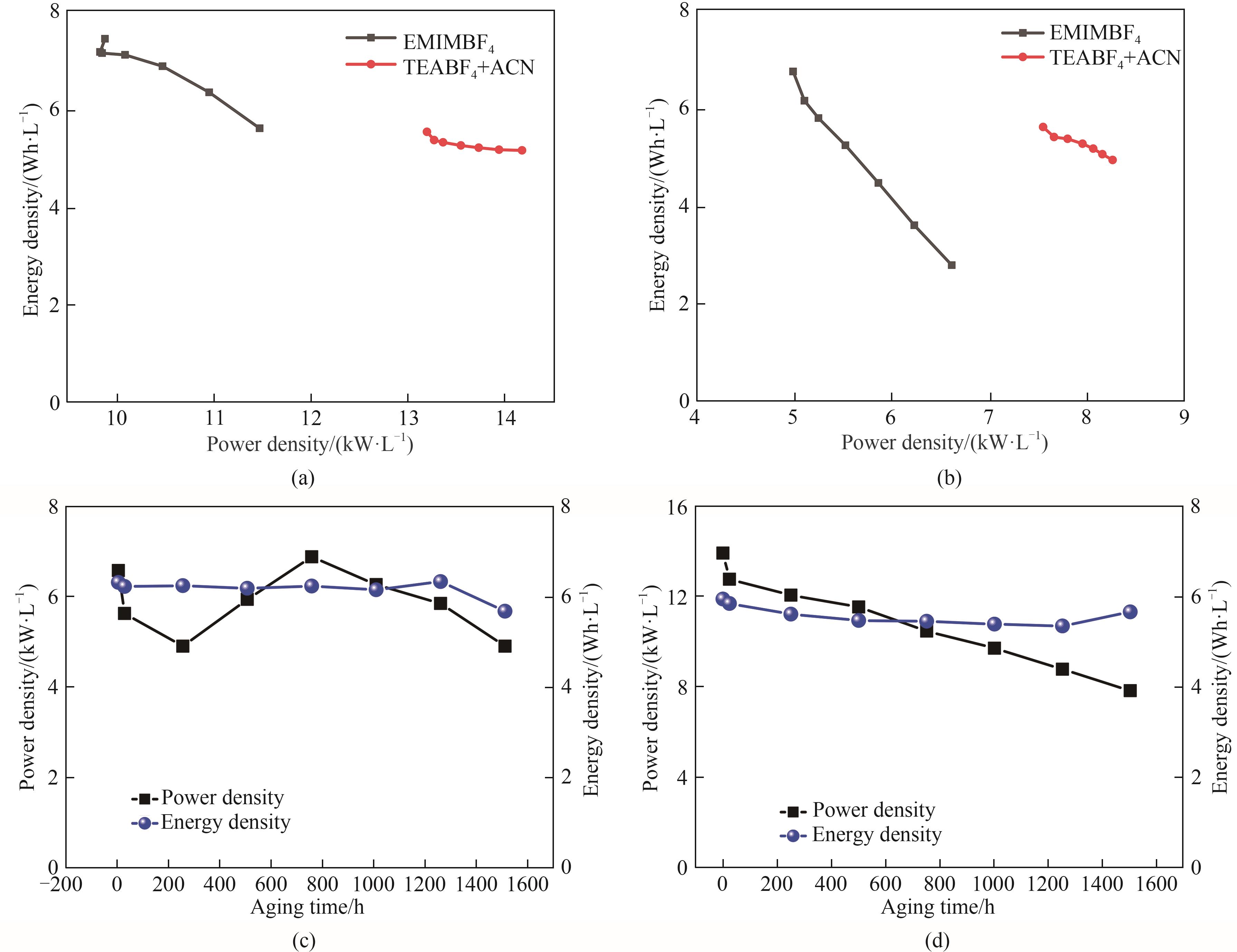

图9 介孔炭-EMIMBF4-泡沫铝和介孔炭-TEABF4/ACN-泡沫铝两体系在高温老化前(a)、后(b)的能量密度与功率密度的比较;随着高温老化的进行EMIMBF4软包(c)、TEABF4/ACN软包(d)的能量密度与功率密度的变化趋势

Fig.9 Comparison of energy density and power density of mesoporous carbon-EMIMBF4-Al foam and mesoporous carbon-TEABF4/ACN-Al foam before (a) and after (b) high temperature aging; The changing trend of energy density and power density of EMIMBF4 pouch (c) and TEABF4/ACN pouch (d) with high temperature aging

| 1 | Kötz R, Carlen M. Principles and applications of electrochemical capacitors[J]. Electrochimica Acta, 2000, 45(15/16): 2483-2498. |

| 2 | Winter M, Brodd R J. What are batteries, fuel cells, and supercapacitors? [J]. ChemInform, 2004, 35(50): 4245-4270. |

| 3 | Inagaki M, Konno H, Tanaike O. Carbon materials for electrochemical capacitors[J]. Journal of Power Sources, 2010, 195(24): 7880-7903. |

| 4 | 郑超, 李林艳, 陈雪丹, 等. 超级电容器百篇论文点评(2017.7.1—2017.12.15)[J]. 储能科学与技术, 2018, 7(1): 20-36. |

| Zheng C, Li L Y, Chen X D, et al. Review of selected 100 recent papers for supercapacitors(Jul. 1, 2017 to Dec. 15, 2017)[J]. Energy Storage Science and Technology, 2018, 7(1): 20-36. | |

| 5 | 时志强, 陈明鸣, 赵朔, 等. 新型微晶炭的结构与电化学电容特性[J]. 物理化学学报, 2008, 24(2): 237-242. |

| Shi Z Q, Chen M M, Zhao S, et al. Structure and electrochemical capacitive behavior of novel crystallite carbon[J]. Acta Physico-Chimica Sinica, 2008, 24(2): 237-242. | |

| 6 | Ruch P W, Cericola D, Foelske A, et al. A comparison of the aging of electrochemical double layer capacitors with acetonitrile and propylene carbonate-based electrolytes at elevated voltages[J]. Electrochimica Acta, 2010, 55(7): 2352-2357. |

| 7 | Ruch P W, Cericola D, Foelske-Schmitz A, et al. Aging of electrochemical double layer capacitors with acetonitrile-based electrolyte at elevated voltages[J]. Electrochimica Acta, 2010, 55(15): 4412-4420. |

| 8 | 张莉, 时红雷. 超级电容器的老化趋势分析[J]. 电子测量与仪器学报, 2018, 32(7): 187-191. |

| Zhang L, Shi H L. Aging tendency Investigation of supercapacitor[J]. Journal of Electronic Measurement and Instrumentation, 2018, 32(7): 187-191. | |

| 9 | 顾帅, 韦莉, 张逸成, 等. 超级电容器老化特征与寿命测试研究展望[J]. 中国电机工程学报, 2013, 33(21): 145-153, 204. |

| Gu S, Wei L, Zhang Y C, et al. Prospects of ageing characteristic and life test research on supercapacitors[J]. Proceedings of the CSEE, 2013, 33(21): 145-153, 204. | |

| 10 | 于金山, 苏展, 裴锋, 等. 超级电容器寿命预测的研究进展[J]. 电镀与精饰, 2020, 42(12): 26-31. |

| Yu J S, Su Z, Pei F, et al. Research progress on life prediction of supercapacitors[J]. Plating & Finishing, 2020, 42(12): 26-31. | |

| 11 | 伍世嘉, 王超, 张丽田, 等. 恒功率充放电条件下的双电层超级电容器循环性能研究[J]. 广东电力, 2020, 33(1): 9-16. |

| Wu S J, Wang C, Zhang L T, et al. Study on cycle performance of electrical double layer capacitors under constant power charging and discharging conditions[J]. Guangdong Electric Power, 2020, 33(1): 9-16. | |

| 12 | Ye L, Liang Q H, Huang Z H, et al. A supercapacitor constructed with a partially graphitized porous carbon and its performance over a wide working temperature range[J]. Journal of Materials Chemistry A, 2015, 3(37): 18860-18866. |

| 13 | Hung K, Masarapu C, Ko T, et al. Wide-temperature range operation supercapacitors from nanostructured activated carbon fabric[J]. Journal of Power Sources, 2009, 193(2): 944-949. |

| 14 | Liu W W, Yan X B, Lang J W, et al. Effects of concentration and temperature of EMIMBF4/acetonitrile electrolyte on the supercapacitive behavior of graphene nanosheets[J]. Journal of Materials Chemistry, 2012, 22(18): 8853. |

| 15 | Tian J R, Cui C J, Xie Q, et al. EMIMBF4-GBL binary electrolyte working at -70℃ and 3.7 V for a high performance graphene-based capacitor[J]. Journal of Materials Chemistry A, 2018, 6(8): 3593-3601. |

| 16 | Lewandowski A, Olejniczak A. N-methyl-N-propylpiperidinium bis(trifluoromethanesulphonyl)imide as an electrolyte for carbon-based double-layer capacitors[J]. Journal of Power Sources, 2007, 172(1): 487-492. |

| 17 | Yuyama K, Masuda G, Yoshida H, et al. Ionic liquids containing the tetrafluoroborate anion have the best performance and stability for electric double layer capacitor applications[J]. Journal of Power Sources, 2006, 162(2): 1401-1408. |

| 18 | Balducci A, Dugas R, Taberna P L, et al. High temperature carbon-carbon supercapacitor using ionic liquid as electrolyte[J]. Journal of Power Sources, 2007, 165(2): 922-927. |

| 19 | Galiński M, Lewandowski A, Stępniak I. Ionic liquids as electrolytes[J]. Electrochimica Acta, 2006, 51(26): 5567-5580. |

| 20 | Armand M, Endres F, MacFarlane D R, et al. Ionic-liquid materials for the electrochemical challenges of the future[J]. Nature Materials, 2009, 8(8): 621-629. |

| 21 | Cui C, Qian W, Yu Y, et al. Highly electroconductive mesoporous graphene nanofibers and their capacitance performance at 4 V[J]. Journal of the American Chemical Society, 2014, 136(6): 2256-2259. |

| 22 | Li J, Wang N, Tian J R, et al. Cross-coupled macro-mesoporous carbon network toward record high energy-power density supercapacitor at 4 V[J]. Advanced Functional Materials, 2018, 28(51): 1806153. |

| 23 | Yang Z F, Tian J R, Yin Z F, et al. Carbon nanotube- and graphene-based nanomaterials and applications in high-voltage supercapacitor: a review[J]. Carbon, 2019, 141: 467-480. |

| 24 | Kong C, Qian W, Zheng C, et al. Raising the performance of a 4 V supercapacitor based on an EMIBF4-single walled carbon nanotube nanofluid electrolyte[J]. Chemical Communications, 2013, 49(91): 10727-10729. |

| 25 | Kong C Y, Qian W Z, Zheng C, et al. Enhancing 5 V capacitor performance by adding single walled carbon nanotubes into an ionic liquid electrolyte[J]. Journal of Materials Chemistry A, 2015, 3(31): 15858-15862. |

| 26 | Yang Z F, Tian J R, Ye Z Z, et al. High energy and high power density supercapacitor with 3D Al foam-based thick graphene electrode: fabrication and simulation[J]. Energy Storage Materials, 2020, 33: 18-25. |

| 27 | Hurilechaoketu, Wang J, Cui C J, et al. Highly electroconductive mesoporous activated carbon fibers and their performance in the ionic liquid-based electrical double-layer capacitors[J]. Carbon, 2019, 154: 1-6. |

| 28 | 骞伟中, 崔超婕, 汪剑, 等. 一种高导电、高导热活性炭及制备系统、制备方法与用途: 110510609B[P]. 2021-04-13. |

| Qian W, Cui C, Wang J, et al. High-conductivity and high-thermal-conductivity activated carbon and preparation system, preparation method and application thereof: 110510609B[P]. 2021-04-13. | |

| 29 | 中华人民共和国工业和信息化部. 中华人民共和国汽车行业标准: 车用超级电容器[S]. 北京: 中国计划出版社, 2015. |

| Ministry of Industry and Information of the People's Republic of China. Automobile & Vehicle Standard of the People's Republic of China: Ultra-capacitor for electric vehicles. [S]. Beijing: China Planning Press, 2015. | |

| 30 | Yu Y T, Cui C J, Qian W Z, et al. Full capacitance potential of SWCNT electrode in ionic liquids at 4 V[J]. J. Mater. Chem. A, 2014, 2(46): 19897-19902. |

| [1] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [2] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [3] | 陈美思, 陈威达, 李鑫垚, 李尚予, 吴有庭, 张锋, 张志炳. 硅基离子液体微颗粒强化气体捕集与转化的研究进展[J]. 化工学报, 2023, 74(9): 3628-3639. |

| [4] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [5] | 王俐智, 杭钱程, 郑叶玲, 丁延, 陈家继, 叶青, 李进龙. 离子液体萃取剂萃取精馏分离丙酸甲酯+甲醇共沸物[J]. 化工学报, 2023, 74(9): 3731-3741. |

| [6] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [7] | 陆俊凤, 孙怀宇, 王艳磊, 何宏艳. 离子液体界面极化及其调控氢键性质的分子机理[J]. 化工学报, 2023, 74(9): 3665-3680. |

| [8] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [9] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [10] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [11] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [12] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [13] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| [14] | 李靖, 沈聪浩, 郭大亮, 李静, 沙力争, 童欣. 木质素基碳纤维复合材料在储能元件中的应用研究进展[J]. 化工学报, 2023, 74(6): 2322-2334. |

| [15] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号